Artificial sandstone physical model and manufacturing method and application thereof

A production method and technology of physical models, applied in the field of geophysical research, can solve problems that cannot truly reflect the rock physical characteristics and seismic response of underground reservoirs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

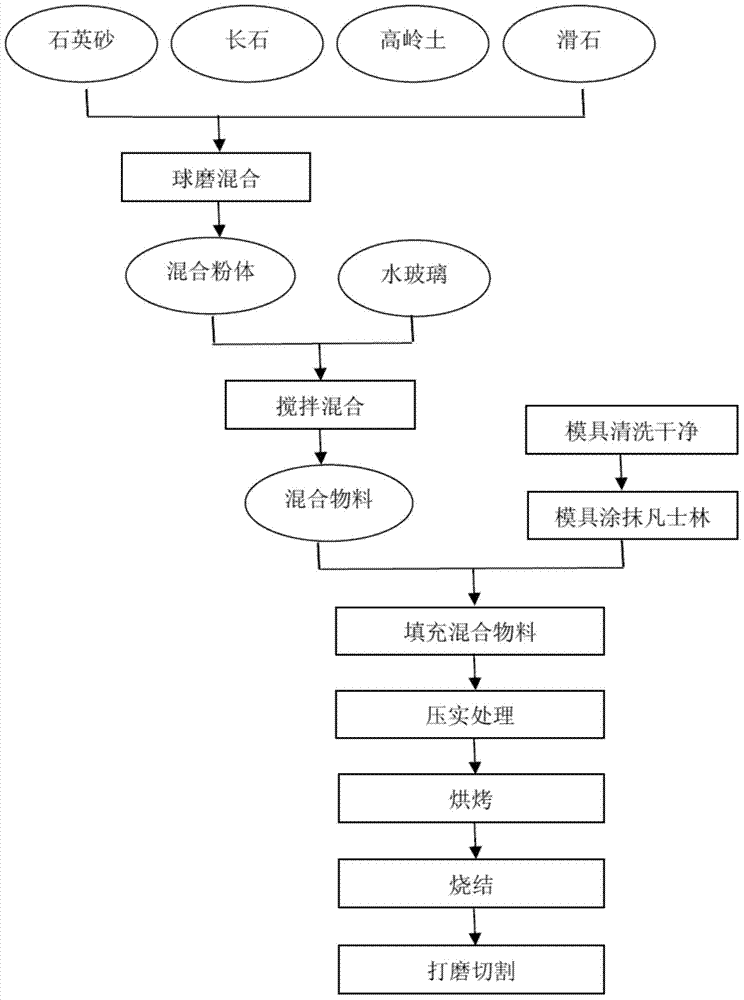

[0036] This embodiment provides a method for making a physical model of artificial sandstone, such as figure 1 As shown, it includes the following steps:

[0037] Put 500 g of 100-mesh quartz sand, 50 g of 350-mesh feldspar, 50 g of 500-mesh kaolin and 50 g of 800-mesh talc into a ball mill jar, put the ball mill jar into a ball mill for dry ball milling, and mix evenly to obtain a mixed powder;

[0038] Add 65g of water glass (the water glass has a modulus of 2.5 and a density of 1.4g / cc) into the mixed powder, put it into a mixer and stir and mix evenly to obtain a mixed material;

[0039] After the cleaned and assembled mold is coated with vaseline, the mixed material is put into the mold to obtain a mold filled with the mixed material;

[0040]The mold filled with the mixed material is placed on a press, and after being compacted for 24 hours under a constant pressure of 20T, the mold is removed and the green body is taken out, and the green body is put into a constant te...

Embodiment 2

[0044] This embodiment provides a method for making a physical model of artificial sandstone, which is basically the same as that of Example 1, except that the quartz sand is a mixture of 200-mesh quartz sand and 400-mesh quartz sand with a weight ratio of 1:1. Mixing (the total weight of quartz sand is 500g), the pressure of compaction treatment is 100T, and the sintering temperature is 1300°C.

[0045] After testing, the artificial sandstone physical model of this embodiment has a density of about 2.3g / cc, a porosity of about 10%, and a longitudinal wave velocity of about 4100m / s. The parameters of the actual natural sandstone are as described in Example 1. The above parameters are close to the physical parameters of the actual natural sandstone and meet the requirements of the simulation experiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| P-wave velocity | aaaaa | aaaaa |

| P-wave velocity | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com