Method and system for evaluating vibration comfort level of excavator

An evaluation method and excavator technology, applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve the problems of less measuring points, vibration analysis and evaluation, human vibration comfort and shock absorber performance Evaluation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0120] Please also refer to Figure 5-9 , an embodiment of the vibration comfort evaluation system of the excavator of the present invention includes:

[0121] An acceleration sensor 201 and a data processing module 202, wherein both the acceleration sensor 201 and the data processing module 202 are installed on the excavator, and the acceleration sensor 201 is connected to the data processing module 202.

[0122] The acceleration sensor 201 is used to collect the acceleration signal corresponding to the vibration generated by the excavator when the excavator is in a vibration test condition. Among them, the vibration test conditions are walking test conditions, simulated excavation test conditions, actual excavation test conditions, single impact test conditions or fixed test conditions.

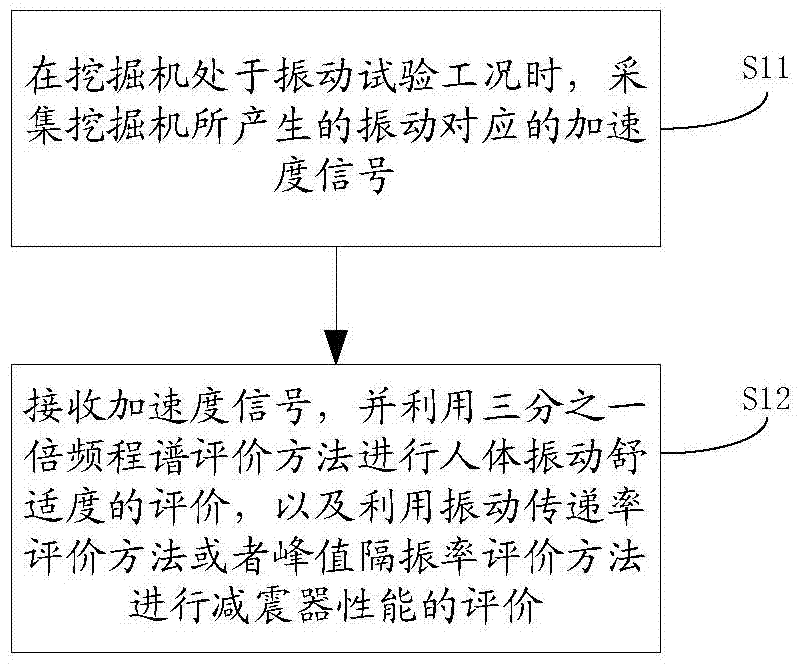

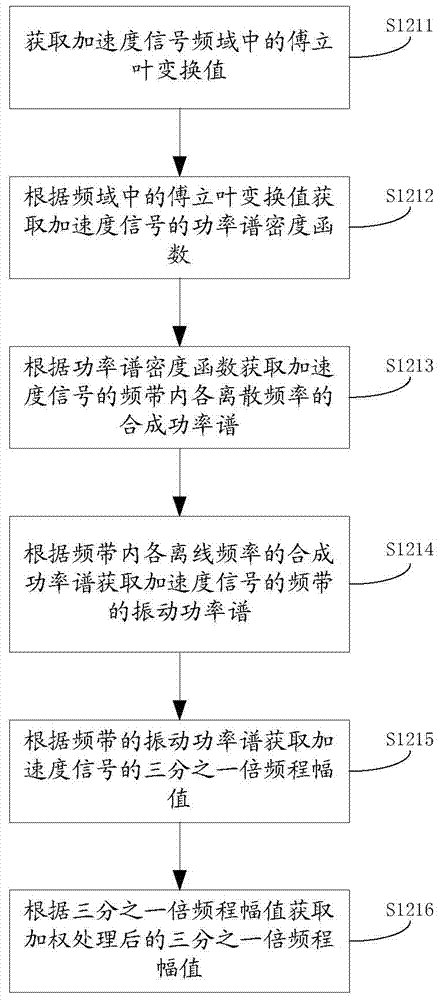

[0123] The data processing module 202 is used to receive the acceleration signal, and use the one-third octave frequency spectrum evaluation method to evaluate the human body vibration com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com