Detection system and control method for bolts and their pretightening force

A technology of bolt pretightening force and control method, which is applied to measure the direction of torque/torsion force during tightening, which can solve the problems of large error range and inability to realize precise control of bolt pretightening force, so as to improve safety and avoid control errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

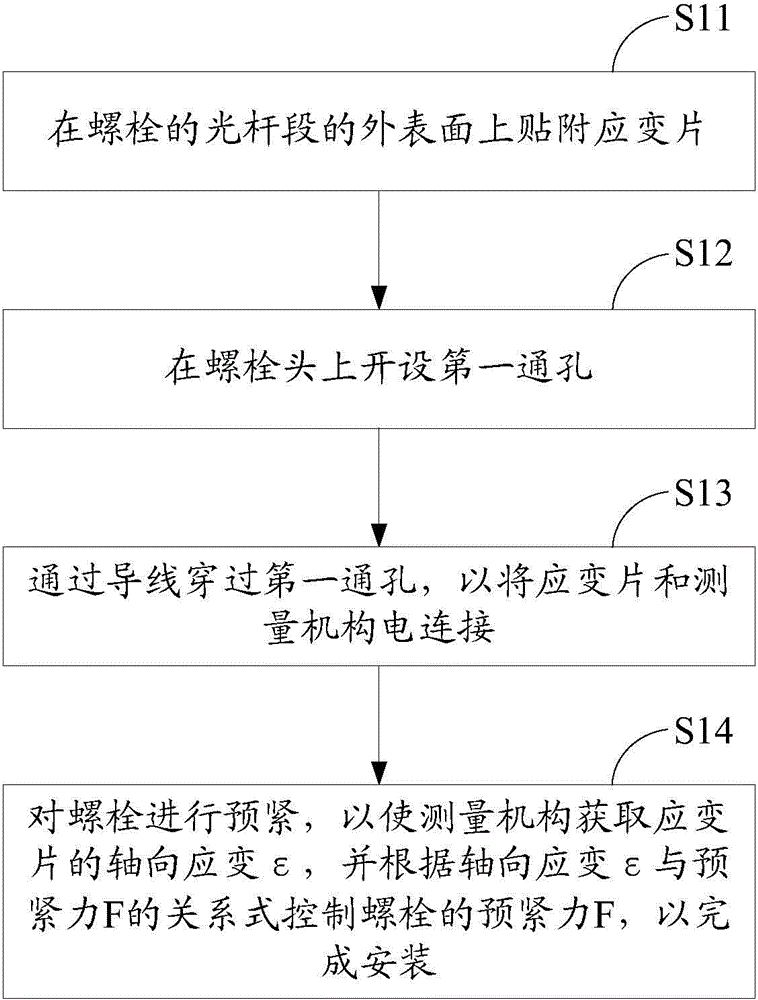

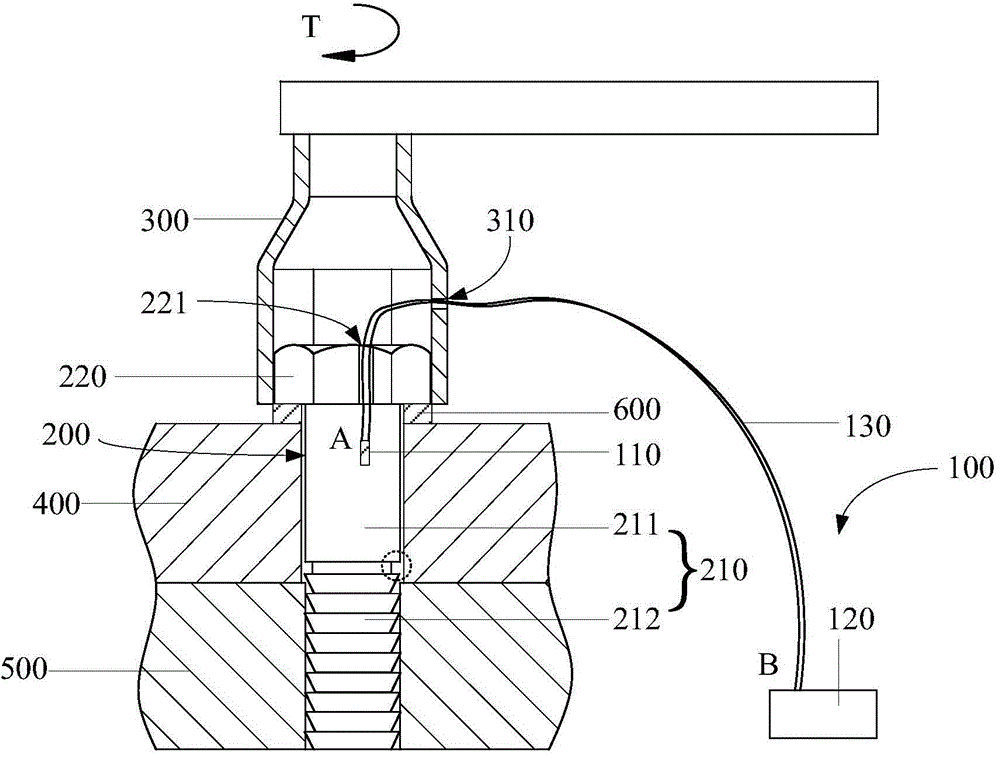

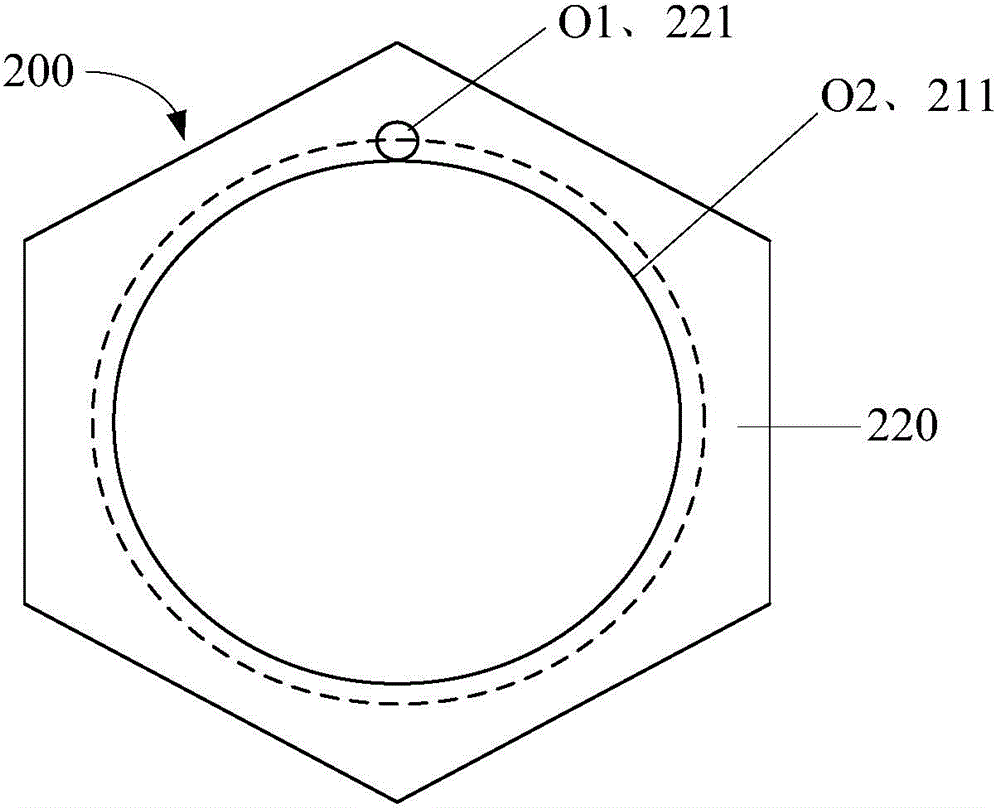

[0022] In order to make the purpose of the present invention, technical scheme and technical effect clearer, below in conjunction with appendix Figure 1~3 Embodiments of the present invention are further described in detail.

[0023] figure 1 It is the flow chart of the first embodiment of the control method of the bolt pretightening force in the present invention, which is in figure 2 The description will be made on the basis of the detection system 100 for bolt pretightening force shown, wherein the detection system 100 includes a strain gauge 110 , a measuring device 120 and a wire 130 for electrically connecting the strain gauge 110 and the measuring device 120 . refer to figure 1 and figure 2 As shown, the control method of the bolt pretightening force of the present embodiment comprises:

[0024] Step S11: Paste strain gauges on the outer surface of the polished rod section of the bolt.

[0025] The detection system 100 for the bolt pretightening force is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com