Equipment floor pipe vibration isolation structure

A technology for equipment layers and pipelines, applied in the direction of pipeline supports, mechanical equipment, pipe components, etc., can solve the problems of low vibration reduction efficiency and high natural frequency, and achieve the effect of high vibration isolation efficiency and load balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

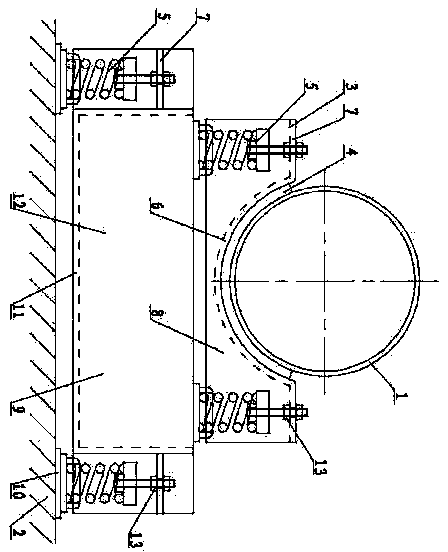

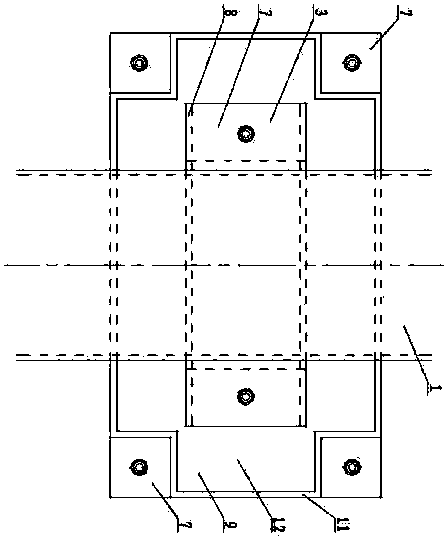

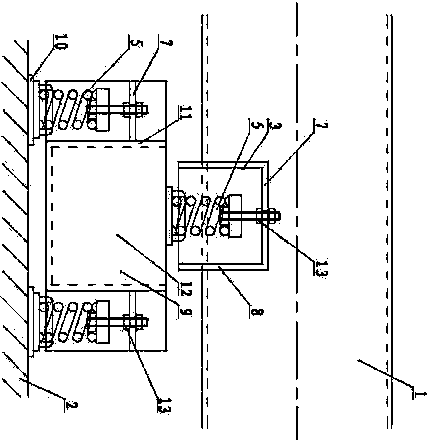

[0018] exist figure 1 , 2 . In the first embodiment shown in 3, it consists of a pipeline vibration isolation member installed under the pipeline (1) and a lower vibration isolation structure installed between the pipeline vibration isolation component and the floor (2). The pipeline vibration isolation component is composed of a pipeline support frame (3), an elastic vibration-absorbing pad (4) and an upper adjustable spring vibration isolator (5). The pipeline support frame (3) is composed of an arc-shaped steel plate (6) (7) and stiffening plate (8) are welded into an integrated component; the lower vibration isolation structure consists of vibration isolation mass (9), bearing steel plate (7), lower adjustable spring vibration isolator (5) and rubber vibration damping pad (10), and the vibration-isolation mass (9) is an integrated component formed by a steel plate frame structure (11) and a counterweight (12). The pipe support frame (3) is installed under the pipe (1), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com