Bored pile construction method for reinforcing cage framework layered installation

A technology of bored piles and construction methods, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of collision hole wall, easy shaking, inconvenience for construction personnel, etc., to avoid collision hole wall, avoid deformation, Good hole cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

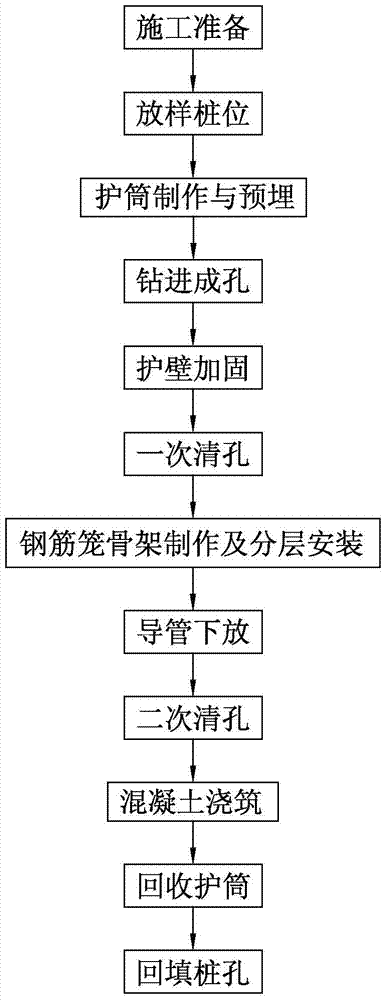

[0033] This construction method comprises the following steps:

[0034] (a) Preparation for construction:

[0035] According to the construction personnel, construction machinery and equipment, materials and materials in the construction organization design, the construction site is arranged and the construction platform is built.

[0036] (b) stake position:

[0037] According to the axis and pile layout in the designed drawings, use the total station to measure and set out the line, then establish a control network on the construction site, then fix the control points and benchmark points with cement mortar, and then use the theodolite to carry out the pile construction according to the control network. For accurate stakeout, a wooden pile is nailed at the center of the pile. For accurate control, an iron nail is nailed on the top of the pile and positioned accurately. At the same time, a guard pile is set in the form of a cross pile.

[0038] (c) Casing fabrication and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com