Vulcanizing mold of rubber bushing

A technology of rubber bushing and vulcanization mold, applied in the field of molds, can solve the problems of insecure product size, inability to smoothly eject the mold, deformation of the lower cavity, etc., and achieve the effects of uniform force, simple structure, and reduced scrap rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

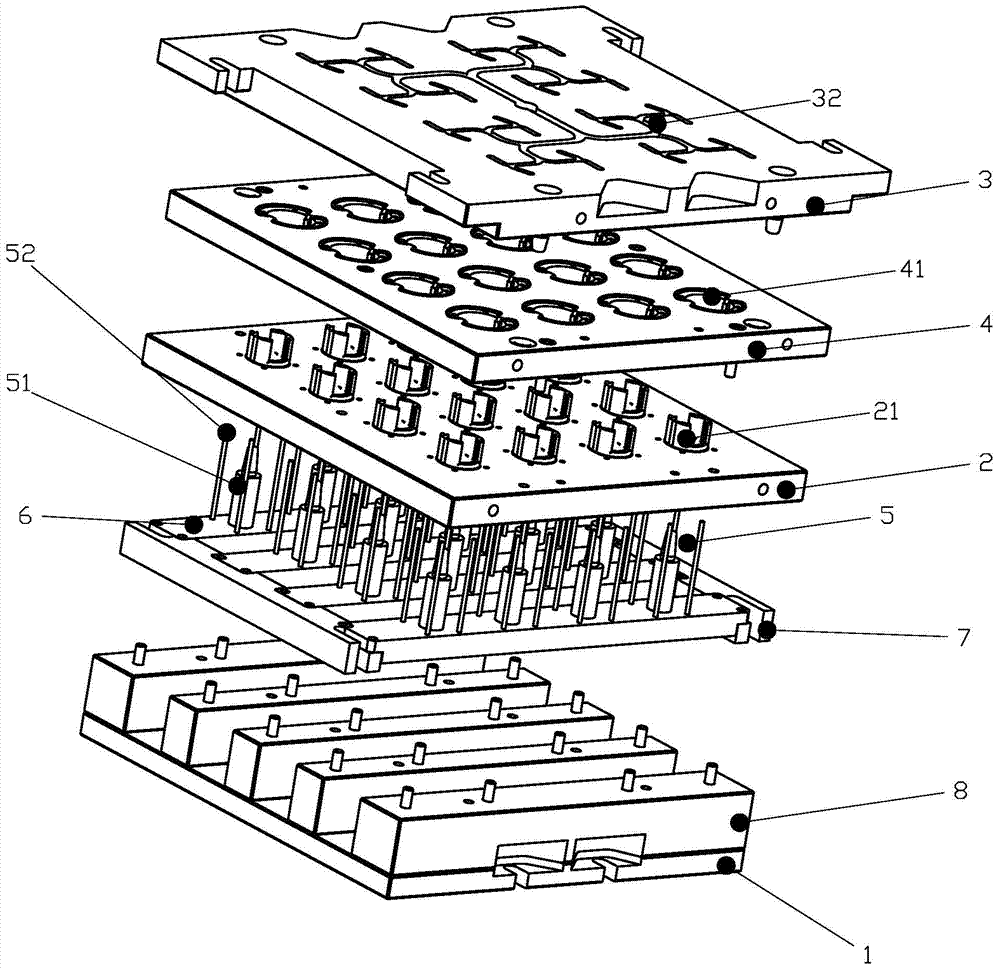

[0018] Embodiment: As shown in the figure, a rubber bush vulcanization mold includes a base plate 1, an ejection mechanism positioned on the base plate 1 that can move up and down, a lower template 2 located on the ejection mechanism and fixed on the base plate 1, and The upper template 3 above the template 2, the product positioning plate 4 between the lower template 2 and the upper template 3, the upper template 3 is provided with a plurality of upper mold cavities 31 and flow channels 32 communicated with the upper mold cavity 31, the lower template 2 is provided with a plurality of lower cavities 21, and the product positioning plate 4 is provided with a plurality of positioning cavities 41, and the upper cavity 31, the lower cavity 21 and the positioning cavity 41 are combined from top to bottom to form accommodating rubber bushes and For a fixed product cavity, the ejector mechanism includes a plurality of ejector pin groups 5, and the ejector pin group 5 includes a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com