Computer numerical control special-shaped stone cutting machine

A cutting machine and special-shaped technology, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of laborious processing of special-shaped stone, secondary pollution, time-consuming and laborious, etc., and achieve easy operation, strong practicability, and simple manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the examples and accompanying drawings, because the following description is only the specific implementation of the present invention, but the protection of the present invention is not limited thereto, and any changes or substitutions conceived by those skilled in the art are all covered within the protection scope of the present invention.

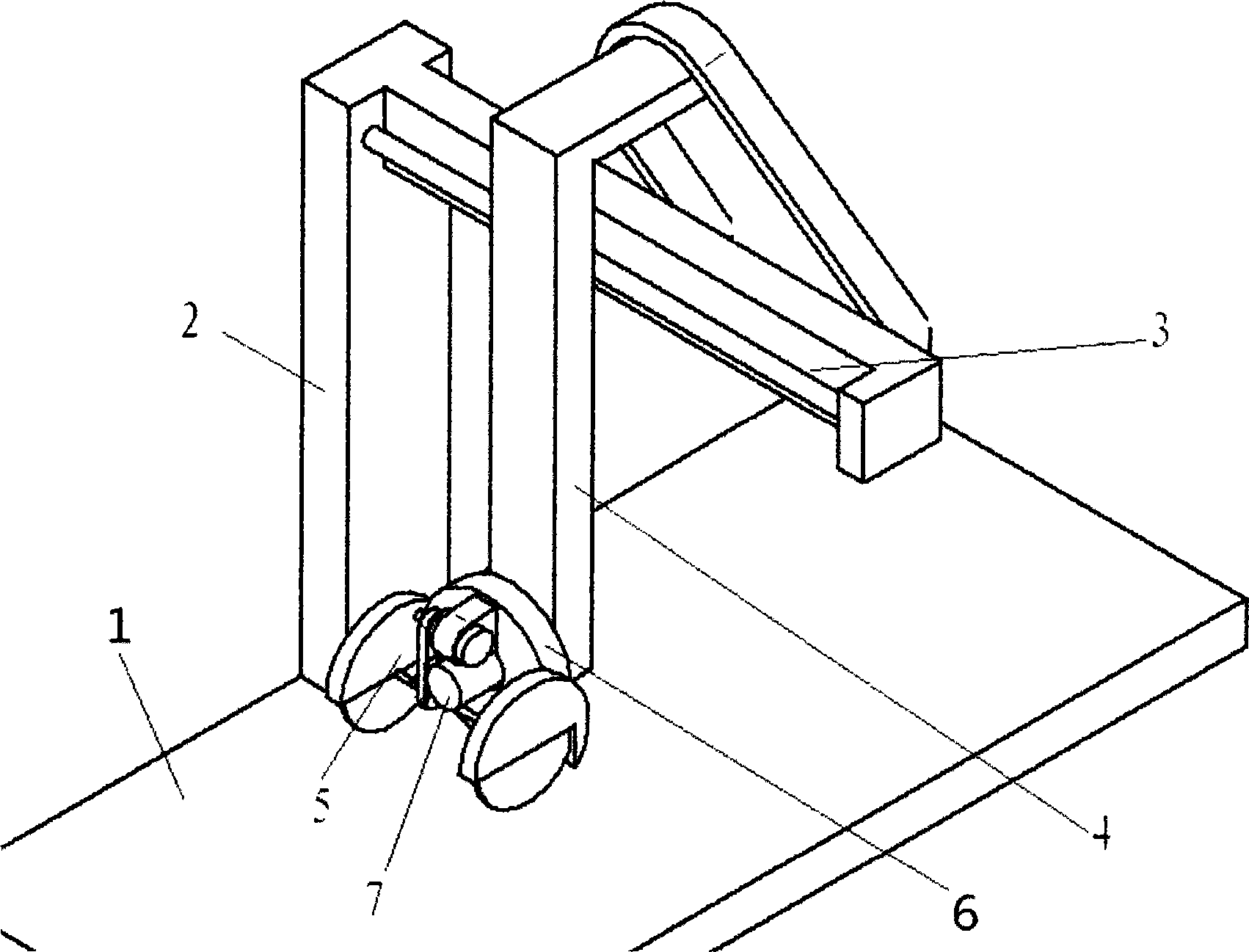

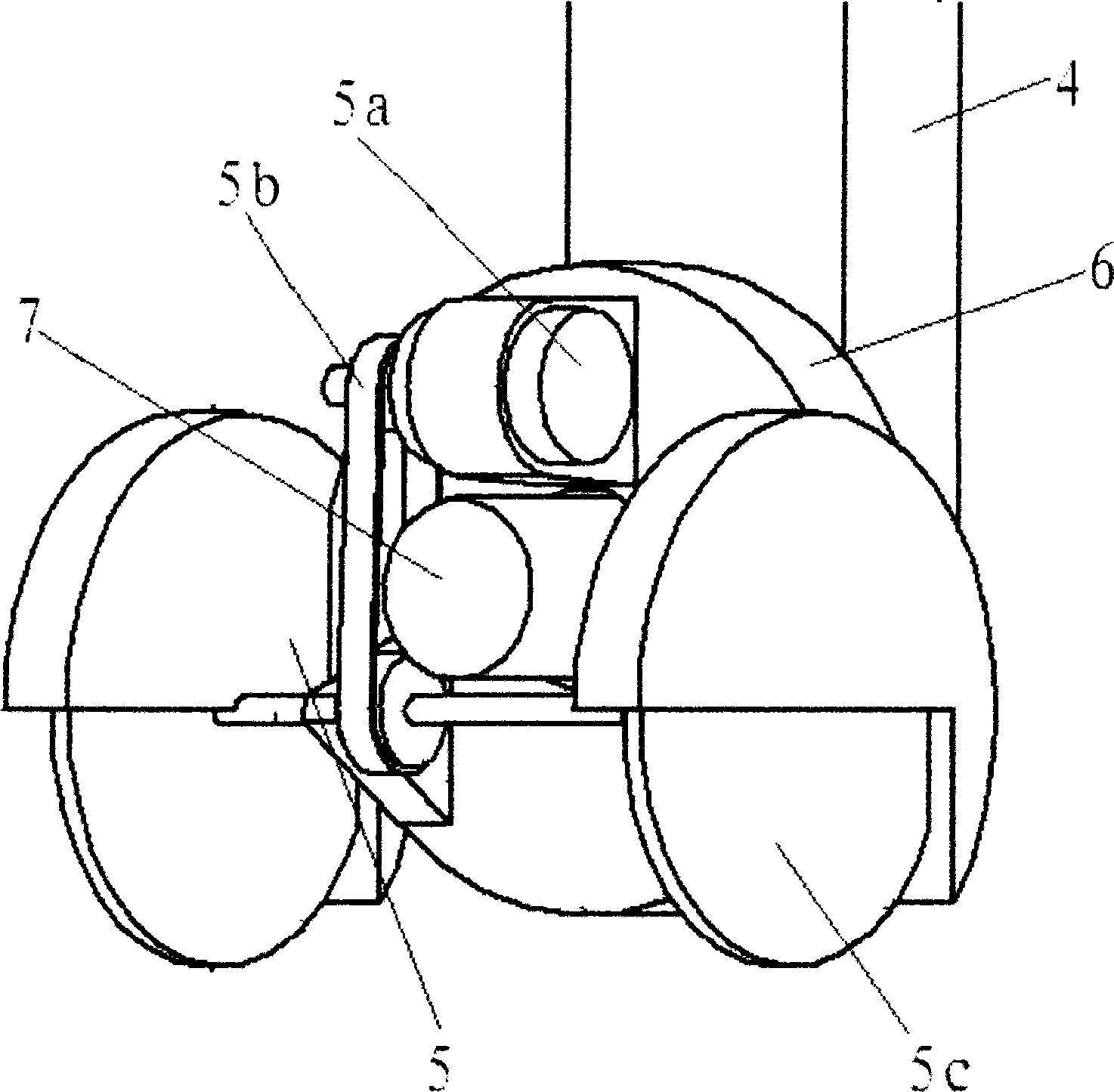

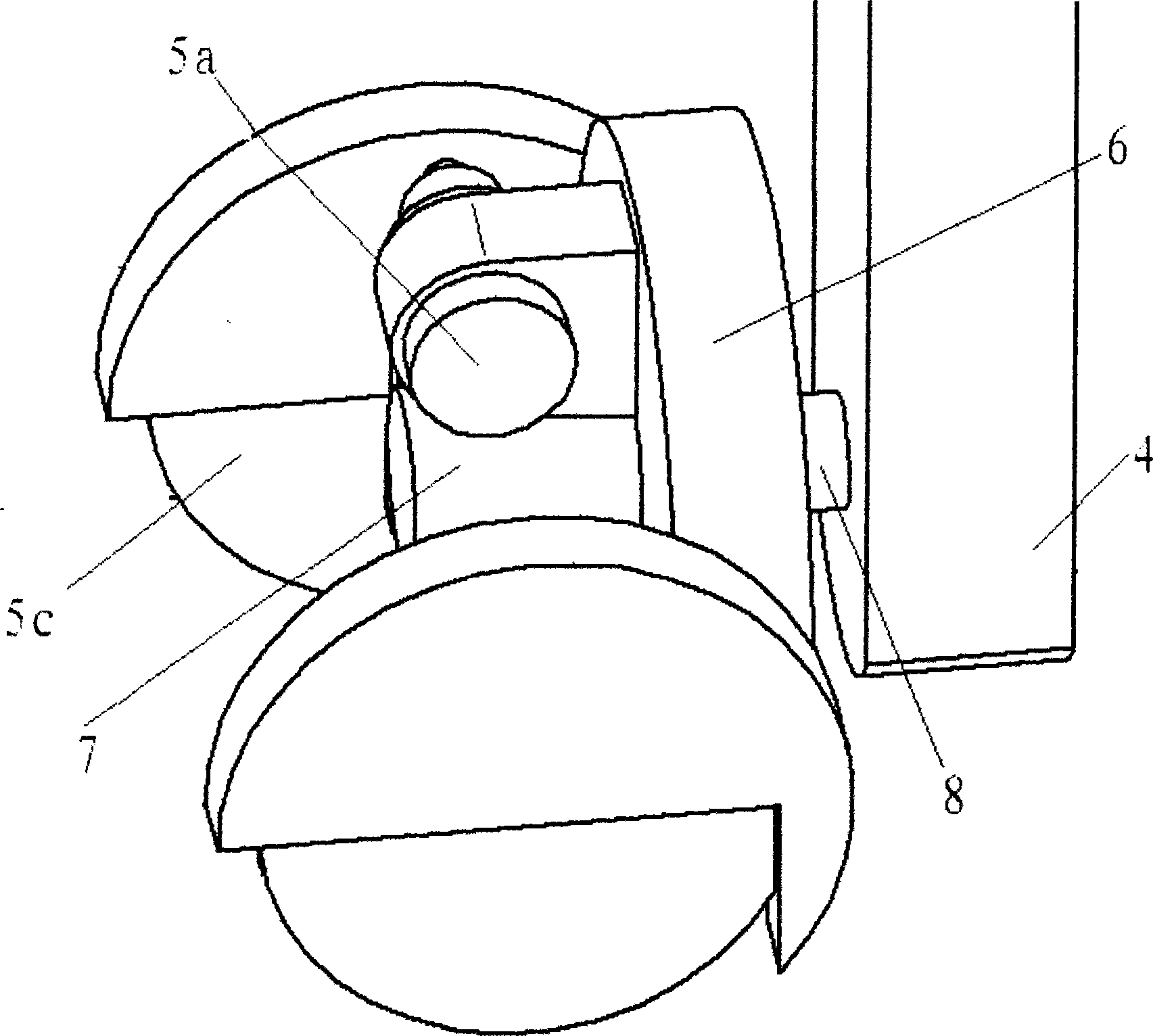

[0015] A computerized numerical control special-shaped stone cutting machine, comprising a workbench 1, a column 2, a beam 3, a vertical beam 4, a knife rest 5, and a beam 3 installed on the column 2, and a transverse guide rail (not shown in the figure) is arranged on the beam 3, The vertical beam 4 is installed on the transverse guide rail of the crossbeam 3, the longitudinal guide rail (not shown in the figure) is arranged on the vertical beam 4, the knife rest 5 is installed on the longitudinal guide rail of the vertical beam, and the knife rest 5 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com