Full-automatic multi-station automobile ABS pile-up valve end cover stamping equipment

A stamping equipment and multi-station technology, applied in the field of die stamping, can solve the problems of difficulty in controlling the pressure, reduce economic benefits, and high scrap rate, and achieve the effects of avoiding the impact of product quality, simplifying the process flow, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

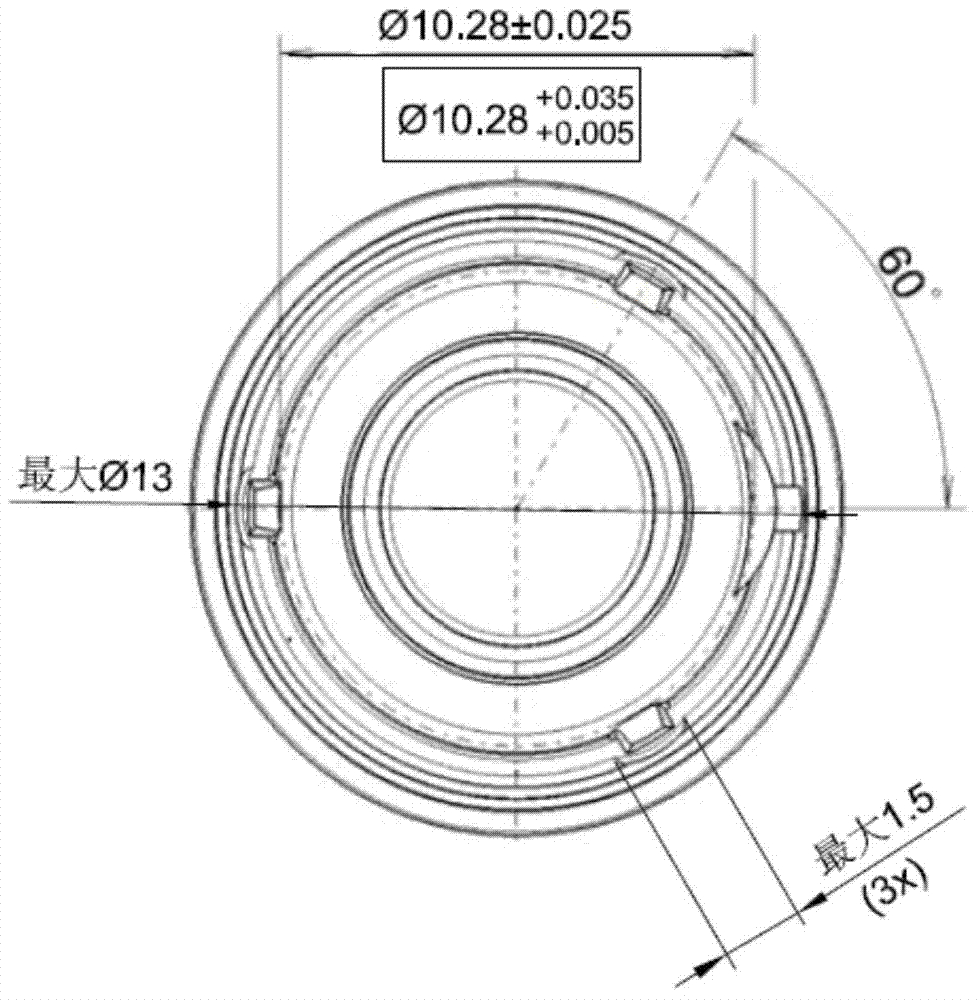

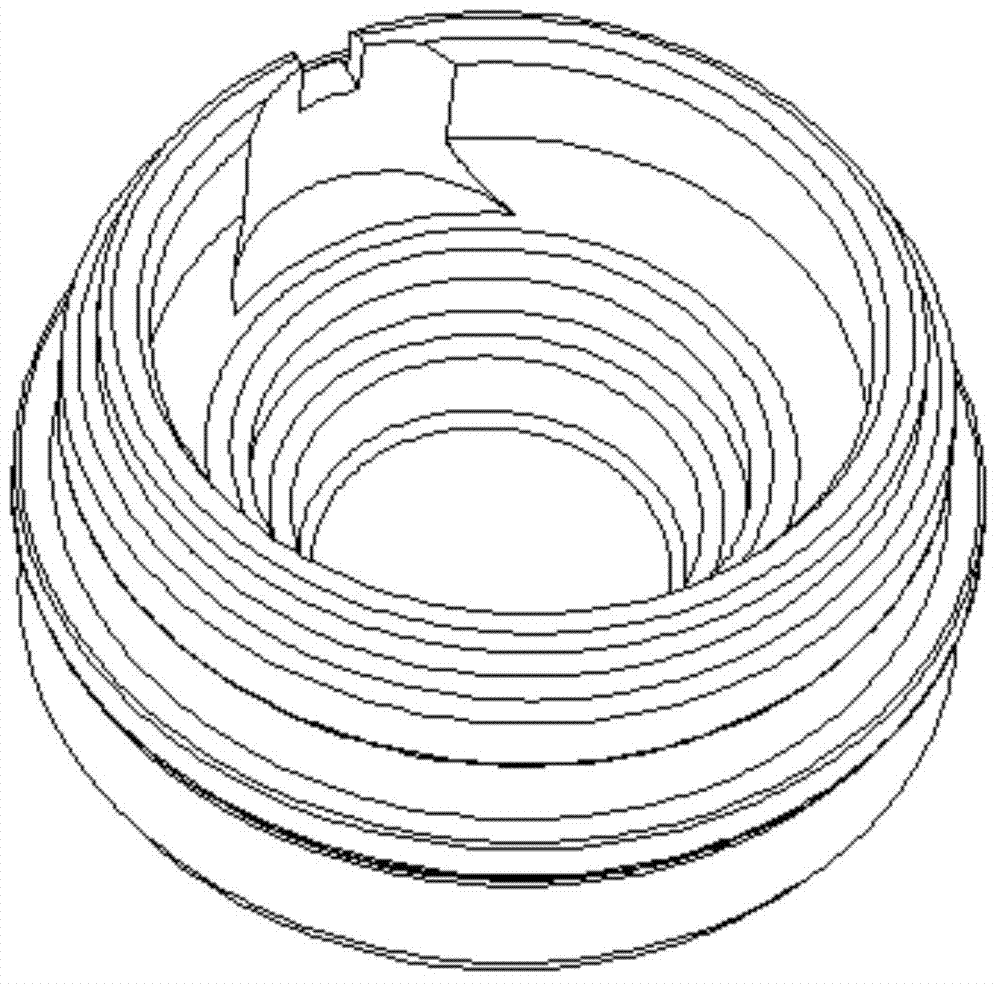

[0038] The invention discloses a full-automatic multi-station automobile ABS integrated valve end cover stamping equipment, which is used for processing such as figure 1 parts shown. see Figure 3-5 , the equipment includes feeding device 1, feeding manipulator 2, positioning device 3, bump stamping die 4, bump stamping mechanism 5, transfer manipulator 6, extrusion rotary table 7, unloading manipulator 8, stamping rotary table 9, connection Material box 10 , extrusion die 11 , bump extrusion mechanism 12 and material pushing mechanism 13 . A pusher mechanism 13 is set at the discharge position of the feeding device 1, and a positioning device 3 is arranged at the front end of the pusher mechanism 13. The feeding manipulator 2 is arranged between the positioning device 3 and the stamping rotary table 9. A bump stamping die 4 and a bump punching mechanism 5 are set, and a transfer manipulator 6 is arranged between the stamping rotary table 9 and the extrusion rotary table 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com