A pipeline inner wall spraying device

A spraying device and pipeline technology, which is applied to the device and coating of the surface coating liquid, can solve the problems such as the influence of the spraying length, the trolley cannot walk freely, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

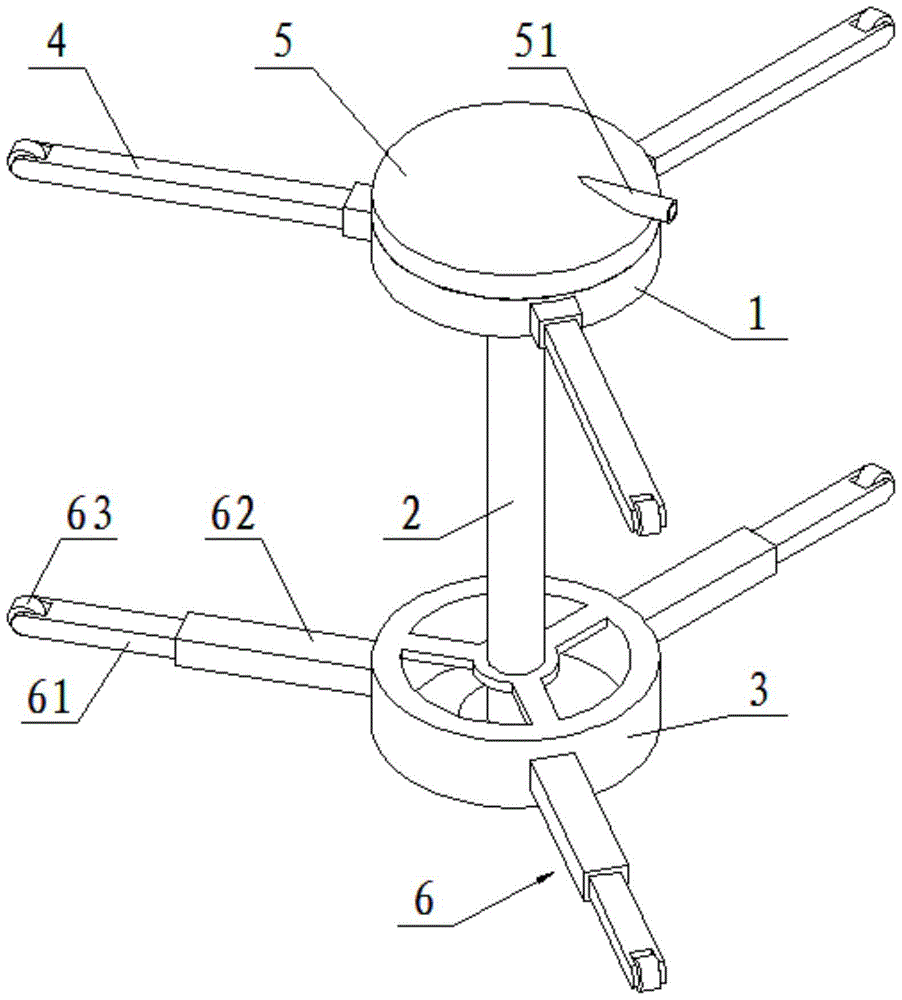

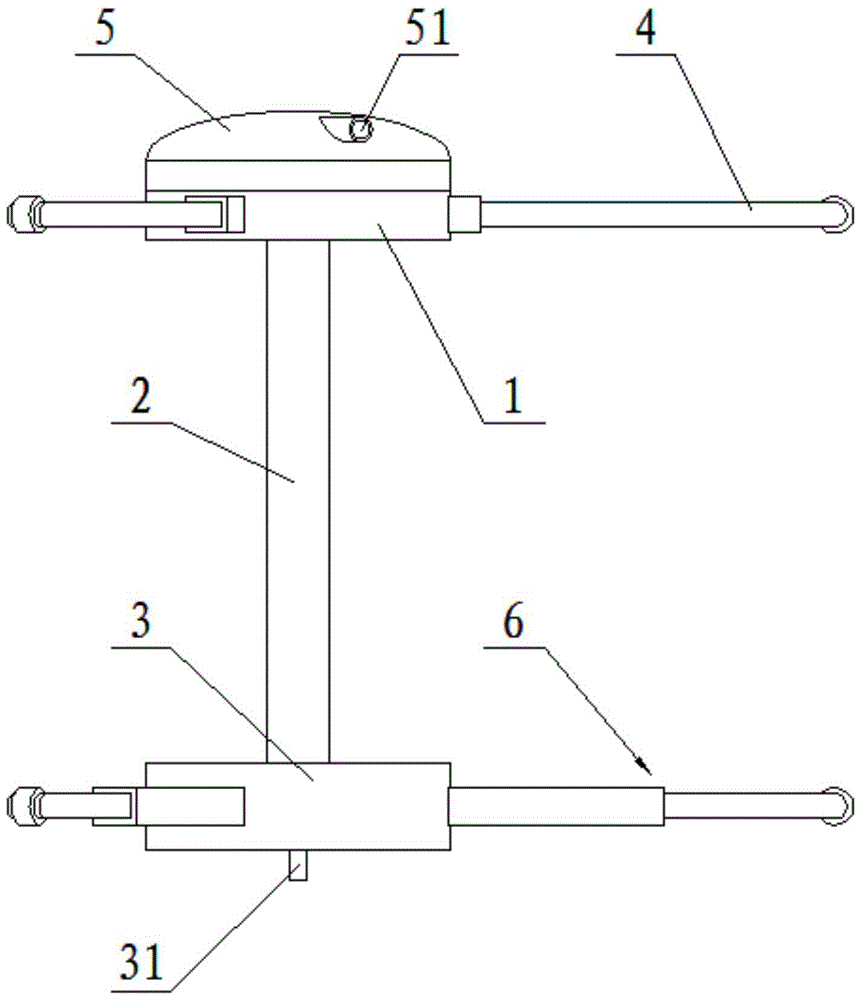

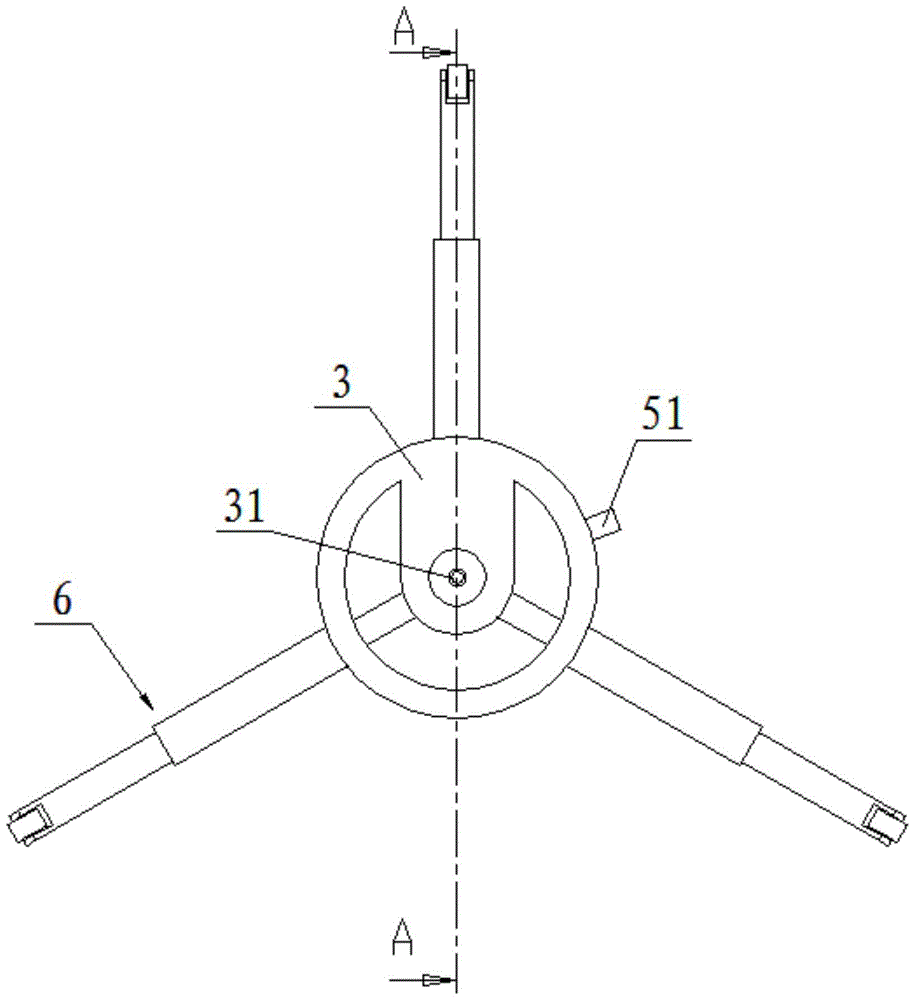

[0025] figure 1 , figure 2 , image 3 , Figure 4 As shown, a pipeline inner wall spraying device includes a front stator 1, a rear stator 3, and a strut 2; one end of the strut 2 is fixedly connected to one end of the front stator 1, and the other end of the strut 2 is connected to the One end of the rear stator 3 is fixedly connected; the other end of the front stator 1 is provided with a nozzle 5 , and at least three groups of first legs 4 are evenly distributed on the circumferential surface of the front stator 1 . The inside of 1 is provided with a first motor 11 that drives the nozzle 5 to rotate; the other end of the rear stator 3 is provided with a nozzle adapter 31, and the circumferential surface of the rear stator 3 is evenly distributed with at least three groups of second Outrigger 6, the interior of the rear stator 3 is provided with a battery 7, the battery 7 is each drive motor (the drive motor can be the first motor 11, the second motor 64, the third motor...

no. 2 example

[0030] like Figure 5 As shown, the structure of the first leg 4 in this embodiment is different from the structure of the first leg 4 in the first embodiment, and the structure of the first leg 4 in this embodiment is different from that of the second leg in the first embodiment. The structure of the legs 6 is the same, and other conditions are the same as those of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com