Extrusion type automatic high-viscosity insulating varnish spraying teleoperator for overhead power transmission line

A technology of automatic spraying and power lines, applied in spraying devices and other directions, can solve problems such as casualties, accidental poisoning of personnel, and failure to guarantee quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

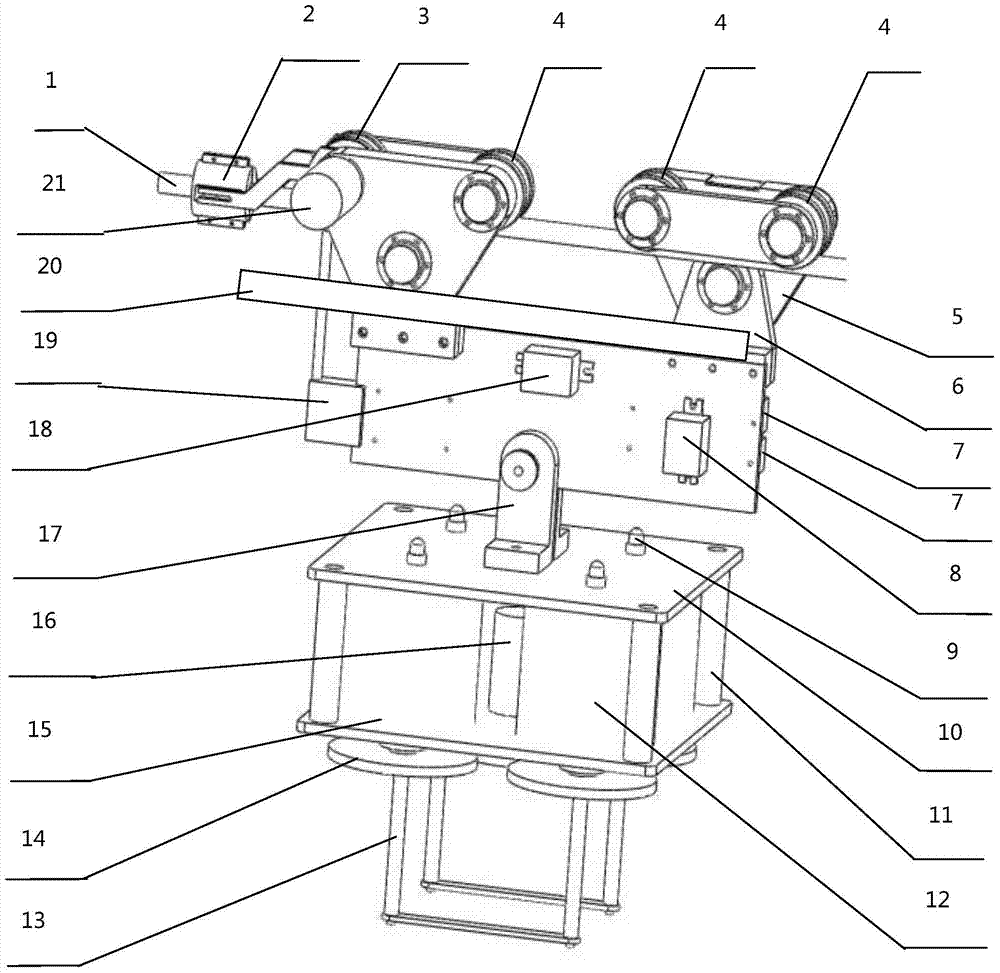

[0025] The extrusion-type overhead power line high-viscosity insulating paint automatic spraying remote control robot of the present invention, its preferred specific implementation is as follows figure 1 Shown:

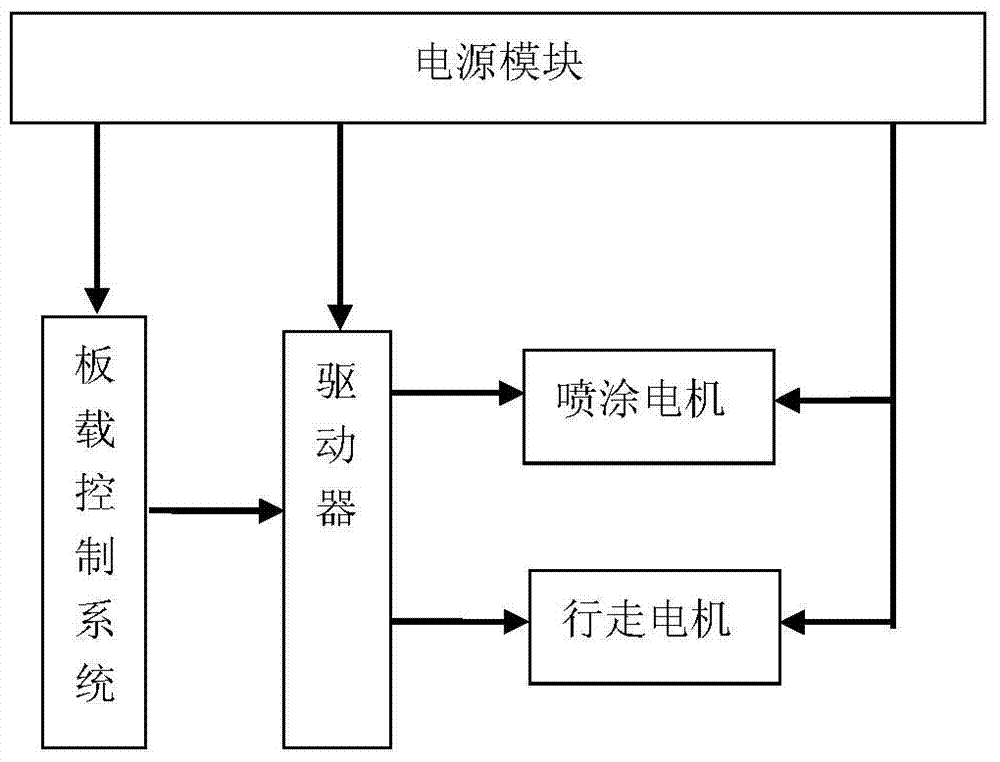

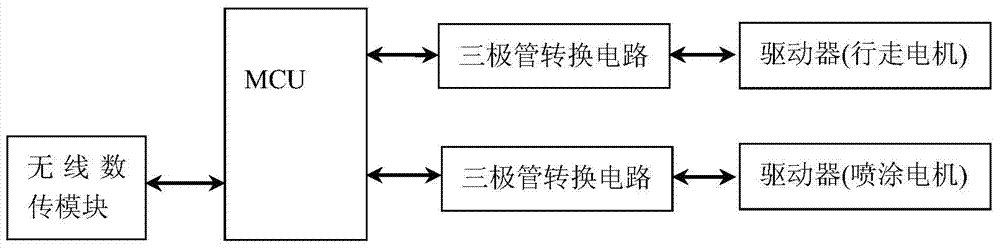

[0026] The specific embodiment of the extrusion-type overhead power line high-viscosity insulating paint automatic spraying remote control robot of the present invention can walk on the overhead power line and the distribution network conductor, and can detect and control the propulsion speed of the spraying motor and the progress of the walking motor in real time through the ground control system Speed realizes efficient and reliable spraying operation of high-viscosity insulating varnish;

[0027] The entire robot system is completed through wireless control under program control, thus ensuring the coordination of the moving speed of the moving car body and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com