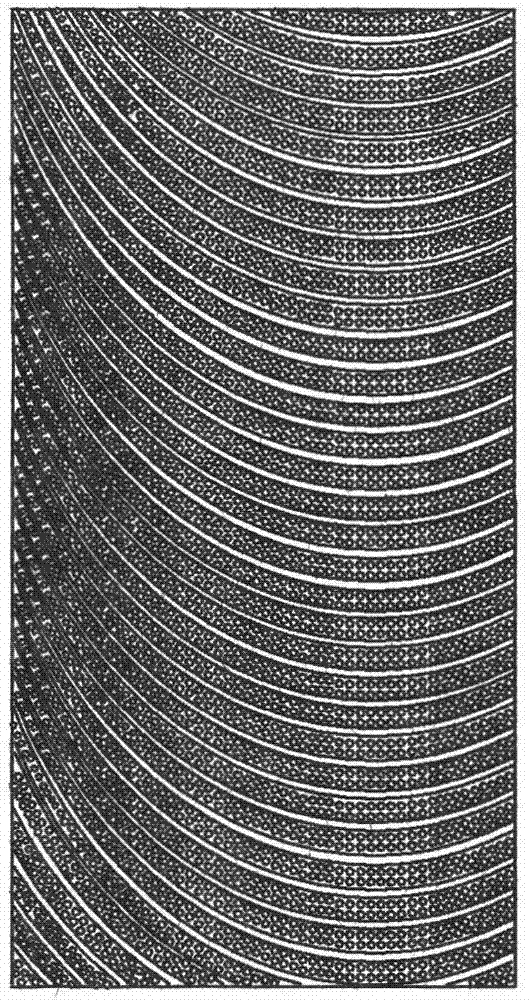

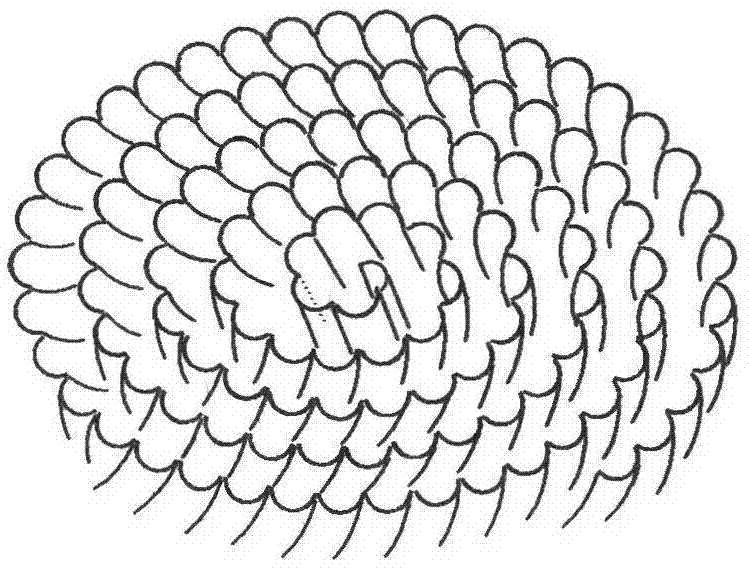

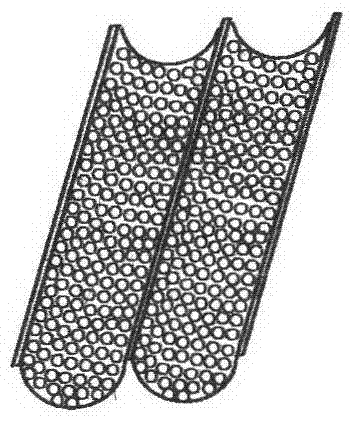

Spiral-plate corrugated structured packing

A technology of structured packing and corrugated packing, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as air friction and collision, increased operating costs, and gas phase kinetic energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The working process of the present invention is that the liquid phase is sprayed from the liquid distributor from the top and slides down along the corrugated packing, and is quickly stretched to form a film, and the gas phase flows upward from the bottom of the tower to contact the liquid countercurrent for mass transfer. Evolving into the inertial flow in the vortex flow field, from the enhanced membrane mass transfer to the spray mass transfer, the gas-liquid mass transfer process is effectively strengthened, and the mass transfer efficiency is greatly improved; and the operation elasticity of the spiral plate corrugated structured packing is higher than that of ordinary corrugated packing. The board is large and the operating range is wide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com