Yoghourt ice cream and preparation method thereof

A technology of yogurt ice cream and ice cream, which is applied in frozen sweets, food science, applications, etc., can solve the problem of lack of yogurt ice cream, etc., and achieve the effect of mellow and natural aroma and smooth taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

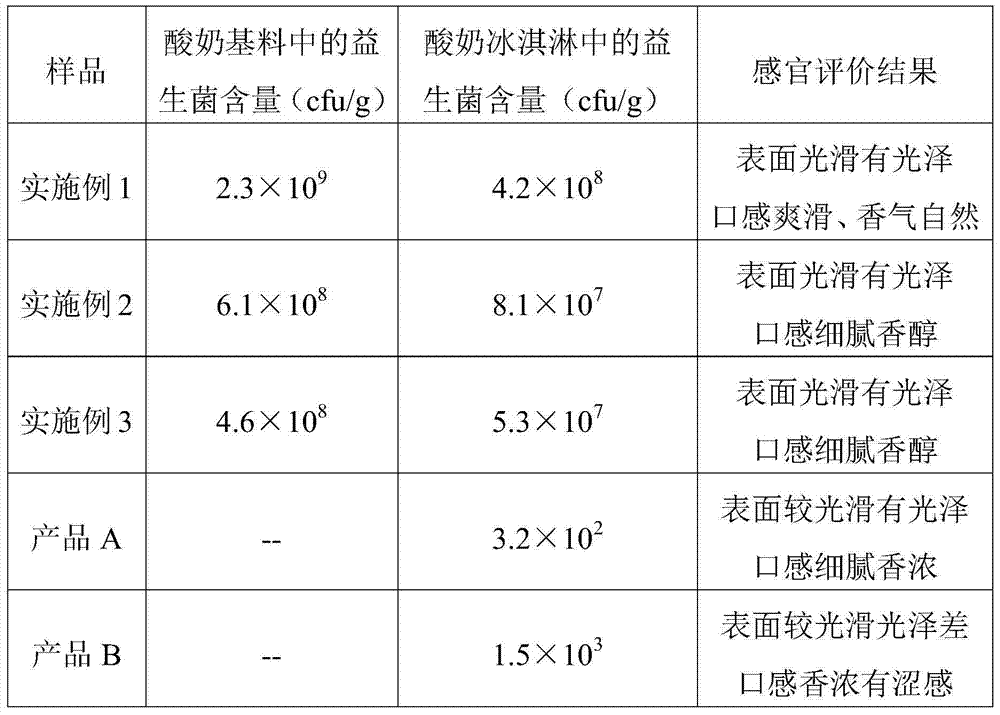

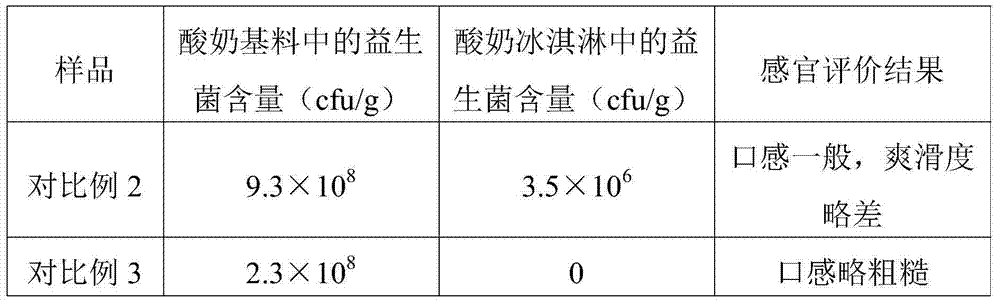

Examples

Embodiment 1

[0037] (1) Preparation of yogurt base

[0038] Mix 92% anti-antibiotic milk and 8% white sugar, homogenize at 63°C and 15MPa pressure, sterilize at 90°C for 5 minutes, then cool to 36°C, inoculate at this temperature, ferment, ferment The end point is 70°T, stir and cool to 6°C, after-cooking for 10 hours for use. The inoculation amount of the inoculation is 0.3u / Kg.

[0039] (2) Preparation of ice cream base

[0040] The raw material formula (by mass percentage) of the ice cream base material of table 1 embodiment 1

[0041] White sugar

20%

whole milk powder

10%

whey protein powder

5%

Anhydrous Cream

5%

thickener

8%

water

52%

[0042] The raw material formula of ice cream base material is as shown in table 1, and the production process step of ice cream base material is:

[0043] 1) Heat 52% water to 60°C, add thickener, white sugar, whole milk powder, whey protein powder, and anhydrous cream in sequence, a...

Embodiment 2

[0049] (1) Preparation of yogurt base

[0050] Mix 90% anti-antibiotic milk and 10% white sugar, homogenize at 60°C and 20MPa pressure, sterilize at 95°C for 7 minutes, then cool to 40°C, inoculate at this temperature, ferment, ferment The end point is 80°T, stir and cool to 4°C, after-cooking for 10 hours for use. The inoculation amount of the inoculation is 0.1u / Kg.

[0051] (2) Preparation of ice cream base

[0052] The raw material formula (by mass percentage) of the ice cream base material of table 2 embodiment 2

[0053] White sugar

15%

skim milk powder

15%

2%

Anhydrous Cream

15%

thickener

5%

water

48%

[0054] The raw material formula of ice cream base material is as shown in table 2, and the production process step of ice cream base material is:

[0055] 1) Heat 47% of water to 65°C, add thickener, white sugar, skim milk powder, whey protein powder, anhydrous cream in sequence, ...

Embodiment 3

[0061] (1) Preparation of yogurt base

[0062] Mix 94% anti-antibiotic milk and 6% white sugar, homogenize at 70°C and 15MPa pressure, sterilize at 85°C for 10 minutes, then cool to 44°C, inoculate at this temperature, ferment, ferment The end point is 90°T, stir and cool to 2°C, after-cooking for 10 hours for use. The inoculation amount of the inoculation is 0.6u / Kg.

[0063] (2) Preparation of ice cream base

[0064] The raw material formula (by mass percentage) of the ice cream base material of table 3 embodiment 3

[0065] White sugar

25%

whole milk powder

12%

4%

cream

10%

thickener

7%

water

42%

[0066] The raw material formula of ice cream base material is as shown in table 3, and the production process step of ice cream base material is:

[0067] 1) Heat 42% water to 70°C, add thickener, white sugar, whole milk powder, whey protein powder, and cream in sequence, and stir for 12 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com