In-line back pressure fluid regulator

A back pressure regulator, fluid regulator technology, applied in fluid pressure control, control/regulation system, fluid pressure control without auxiliary power, etc., can solve problems such as small pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

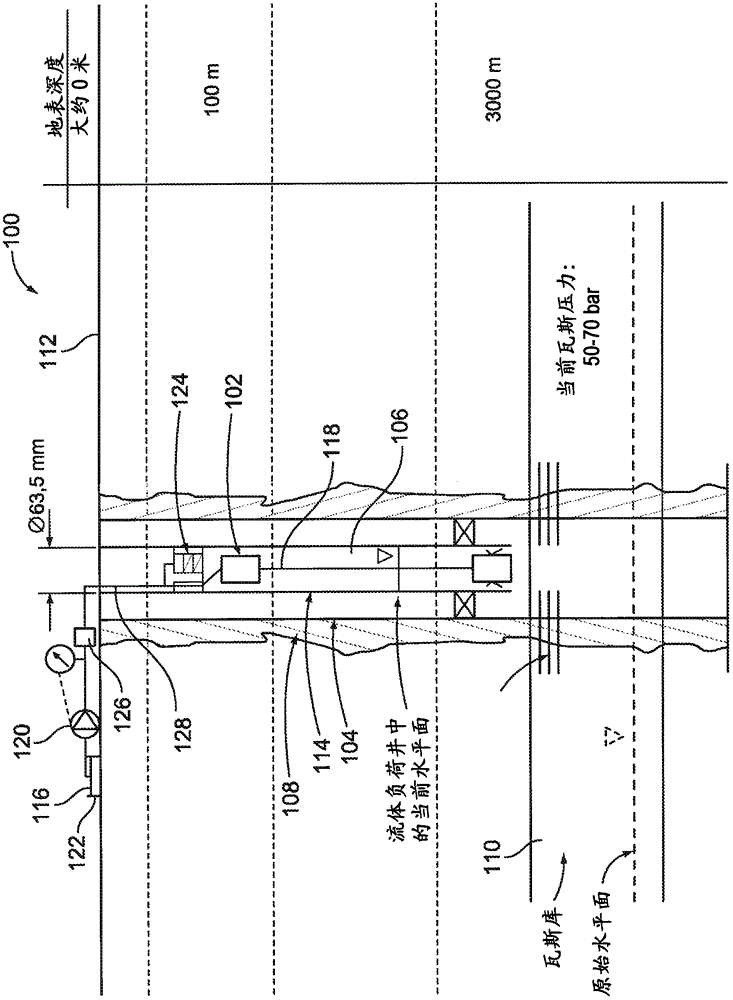

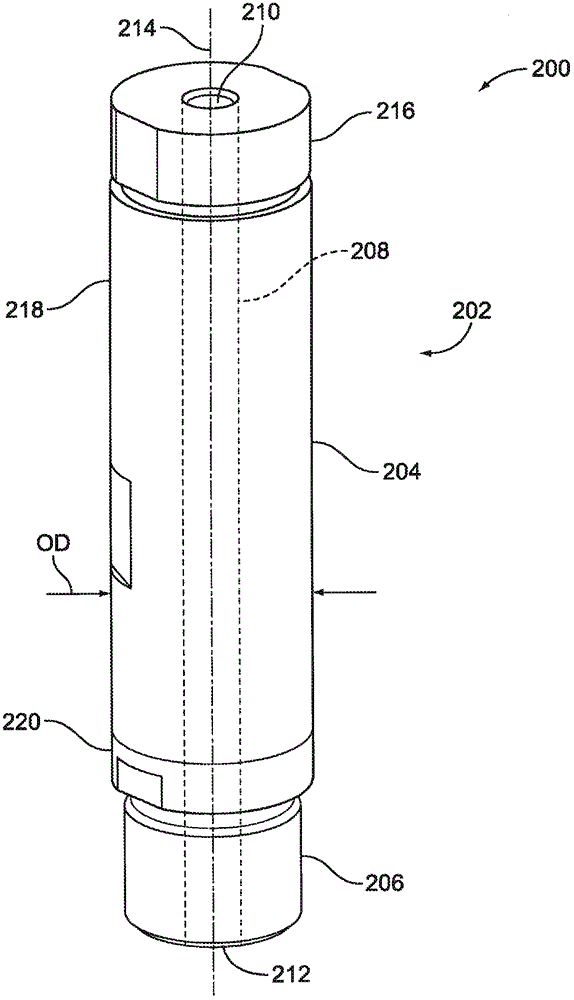

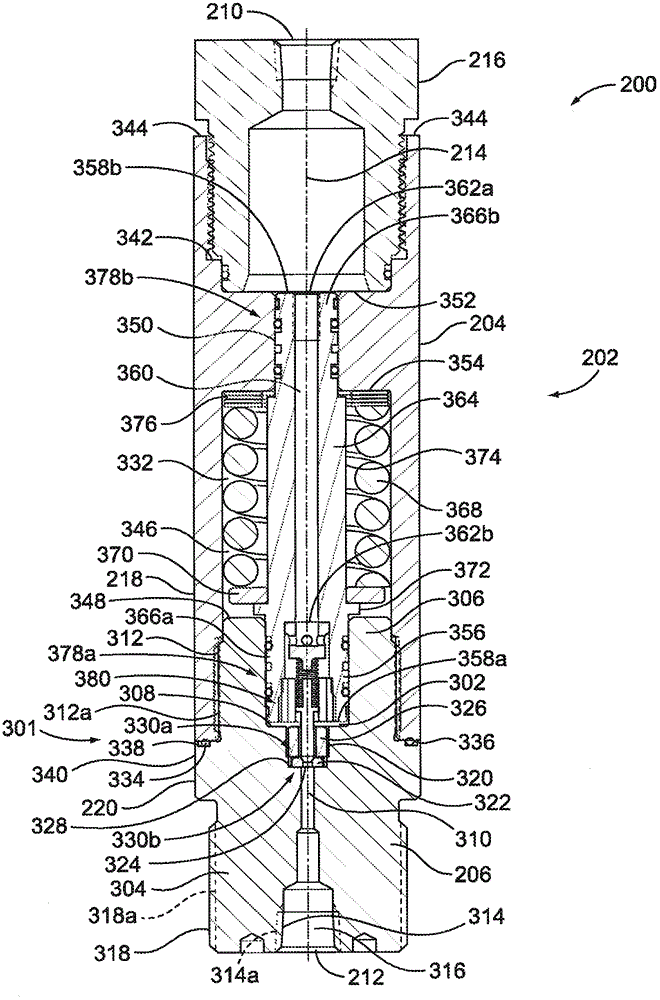

[0016] The coaxial backpressure fluid regulators described herein have a housing that defines a substantially straight or linear fluid flow path between an inlet and an outlet. More specifically, exemplary backpressure fluid regulators may be coaxially coupled with respect to a flow path of a process fluid system. For example, the inlet, outlet, flow control element, loading chamber, and sensing chamber of the exemplary fluid regulators described herein are coaxially aligned to define a substantially straight or linear fluid flow path for the backpressure fluid regulator. As a result, the example backpressure fluid regulators described herein provide a substantially smaller or reduced envelope or footprint compared to conventional backpressure fluid regulators. Accordingly, the example backpressure fluid regulators described herein may be advantageously used in applications with relatively small or severe space constraints (eg, exploratory well applications). Additionally, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com