Lithium battery for electric vehicle

A technology for lithium batteries and electric vehicles, which is applied in lithium batteries, non-aqueous electrolyte batteries, battery pack components, etc. It can solve the problems of battery shape deformation, high cost, and weak welding, so as to reduce battery failure rate and improve battery quality. Reliability, effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present application is further described in conjunction with the following examples.

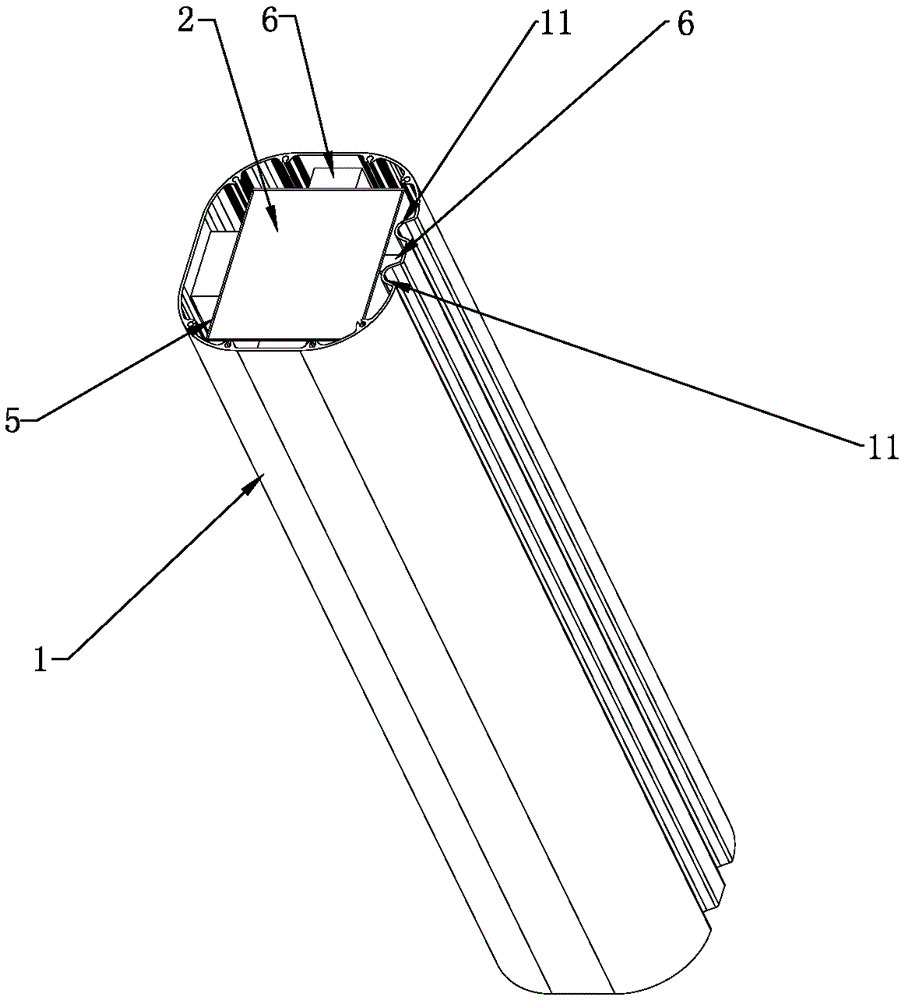

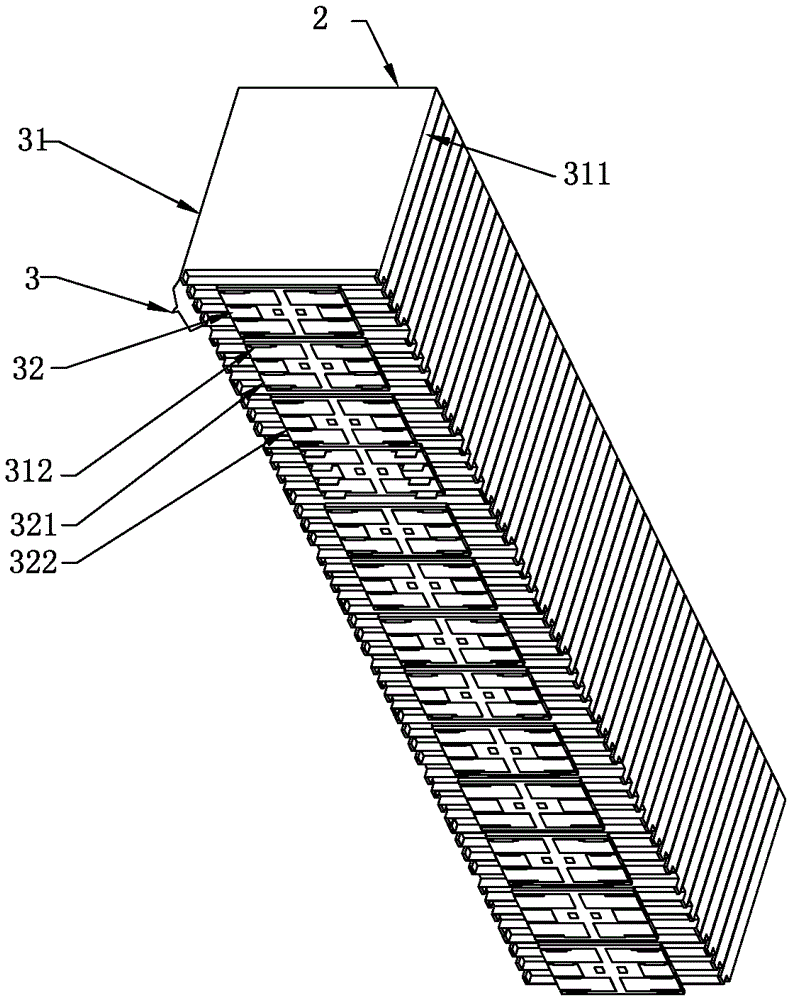

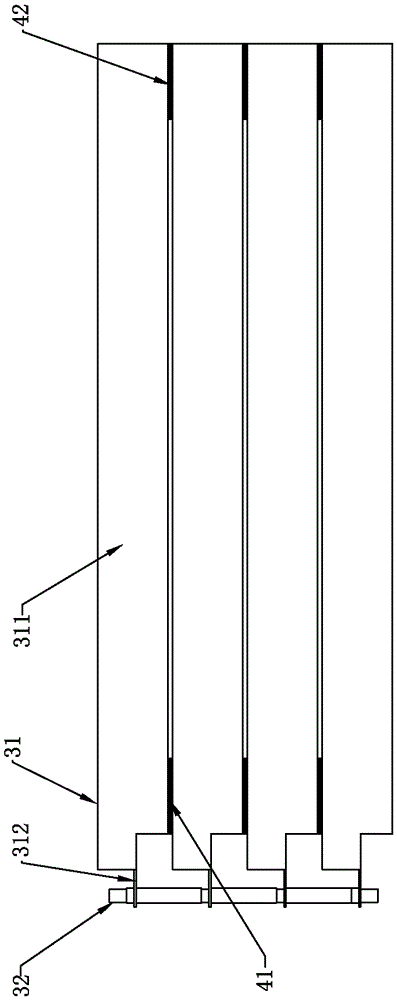

[0025] A specific embodiment of a lithium battery for an electric vehicle in the present application, such as Figure 1 to Figure 4 As shown, it includes: a casing 1, the inner cavity of the casing 1 is provided with a battery core group 2, the battery core group 2 includes a battery module 3, and the battery module 3 includes a connecting plate 32 and at least two A battery chip 31, the connection plate 32 includes a board body 323 made of insulating material, the board body 323 is provided with a pad 321 and at least two sets of tab holes 322, and the battery chip 31 includes a cell body 311 and the cell tab 312 connected to one end of the cell body 311, the cell tab 312 passes through the tab hole 322 from the back of the connecting plate 32, bends toward the pad 321, and is welded on the On the pad 321 , all the cell bodies 311 are sequentially stacked and fixed, and supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com