Winding method and structure of a high-frequency transformer

A high-frequency transformer and winding technology, applied in the field of transformers, can solve the problems of unstable winding voltage, poor coupling of high-frequency transformer windings, and poor tightness and flatness of high-frequency transformers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

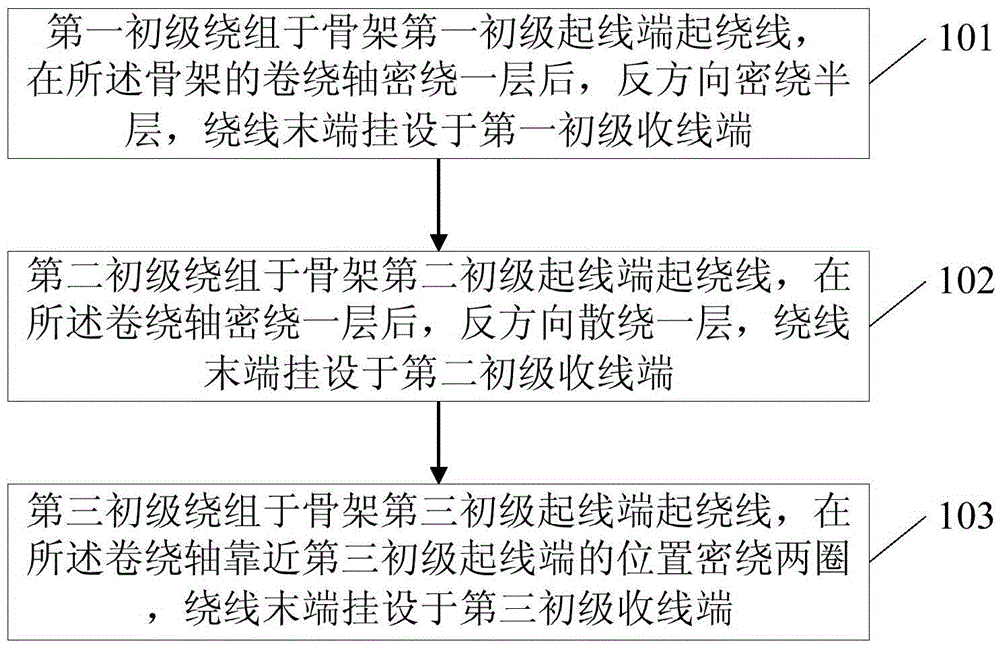

[0016] figure 1 It is a flow chart of the high frequency transformer winding method provided by the first embodiment of the present invention. Such as figure 1 As shown, the method provided by the embodiment of the present invention includes:

[0017] Step 101, the first primary winding is wound at the first primary starting end of the frame, after the winding axis of the frame is tightly wound for one layer, the opposite direction is tightly wound for half a layer, and the end of the winding is hung on the first primary winding end. end of line.

[0018] Step 102, the second primary winding is wound at the second primary starting end of the skeleton, after the winding shaft is tightly wound for one layer, the winding shaft is wound one layer in the opposite direction, and the end of the winding is hung on the second primary winding end .

[0019] Step 103, the third primary winding is wound at the third primary start-up end of the skeleton, close-wound two turns at the po...

Embodiment 2

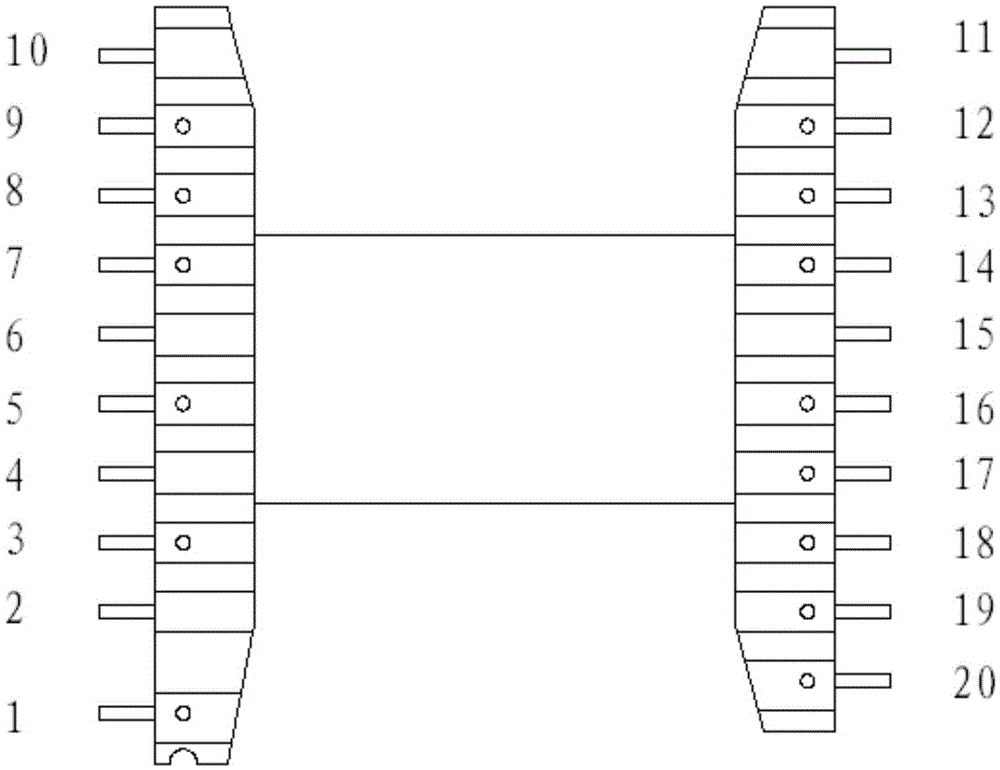

[0027] figure 2 It is a schematic diagram of the winding method of the high-frequency transformer provided by the second embodiment of the present invention. This embodiment provides a preferred embodiment based on the first embodiment. Such as figure 2 As shown, the method provided by the embodiment of the present invention includes:

[0028] The first primary winding starts 20 strands of enamelled copper wire at the first primary starting end 5 of the skeleton, and the 20 strands of enamelled copper wire form a counterclockwise twisted winding, after the winding shaft of the skeleton is tightly wound for one layer Add a layer of insulating tape, and wind half a layer in the opposite direction, and the end of the winding is hung on the end 7 of the first primary take-up end.

[0029] The first secondary winding starts with 27 strands of enamelled copper wires at the first secondary starting ends 12, 13 and 14 of the skeleton, and divides them into counterclockwise twiste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com