A test device for testing rock fracture toughness

A technology of fracture toughness and test equipment, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of shearing of difficult rocks and measurement of composite fracture toughness, and achieve simple loading and unloading process and easy operation Easy to use, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

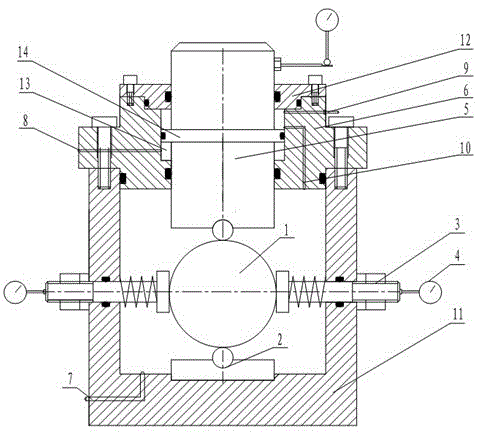

[0016] Below in conjunction with accompanying drawing and operating principle the present invention is described in detail, see figure 1 :

[0017] A test device for testing the fracture toughness of rocks, the device consists of a pad 2, a spring positioning device 3, a dial gauge 4, a loading shaft 5, an upper cover 6, an oil inlet 7, an exhaust port 8, an oil outlet 9, The oil pipeline 10, the box body 11, the top cover 12, the oil chamber 13, and the collar 14 are composed of coaxial circular holes symmetrically arranged on the two side walls of the box body 11, and the spring positioning devices 3 are respectively movable and placed on the coaxial circular holes. The hole is used to fix the sample 1; the outer wall of the loading shaft 5 is provided with a collar 14 whose section is concentric with the section of the loading shaft. The upper cover 6 is bolted, and the upper cover 6 is set on the loading shaft 5 and connected with the box body 11 by bolts. There is an oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com