Method for determining occurrence state of mercury in desulfurization by-product

A technology of desulfurization by-products and occurrence state, which is applied in the field of measuring the occurrence state of mercury in desulfurization by-products, and can solve problems such as unsuitable desulfurization by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

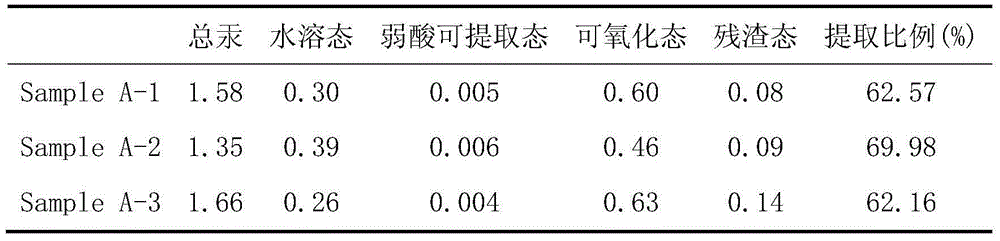

Embodiment 1

[0027] Select a semi-dry desulfurization ash sample from a power plant in Zhejiang, divide it into three equal parts, each 5g, and mark it as Sample A-1, Sample A-2, and Sample A-3. At first adopt atomic fluorescence spectrophotometry to measure the content of total mercury in the sample, then use the method in the present invention to measure respectively the content of mercury in each extraction step in three groups of samples to be tested, concrete determination steps are:

[0028] (1) Take the sample to be tested that has been ground through a 60-mesh sieve, add deionized water, stir at a constant temperature of 30°C, shake for 30 minutes, let stand for 8 hours, centrifuge at 4000rpm for 10 minutes, take the supernatant after centrifugation and filter to be tested, the residue dry. This step extracts water-soluble mercury, mainly including HgCl 2 , HgNO 3 , HgSO 4 etc., liquid-solid ratio 1:5g / ml (liquid-solid ratio will affect the extraction ratio of mercury, within th...

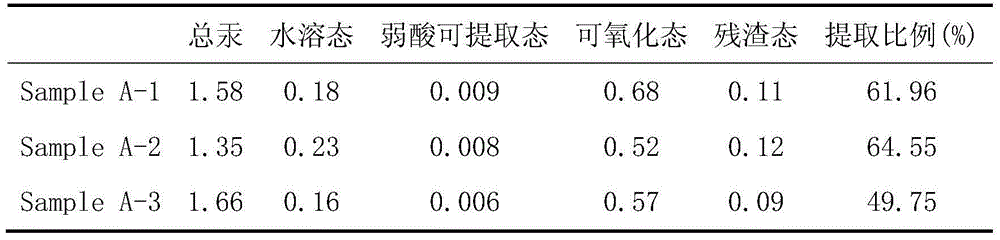

Embodiment 2

[0056] Select a wet desulfurization gypsum sample from a power plant in Zhejiang, divide it into three equal parts, each 5g, and mark it as Sample B-1, Sample B-2, and Sample B-3. At first adopt atomic fluorescence spectrophotometry to measure the content of total mercury in the sample, then use the method in the present invention to measure respectively the content of mercury in each extraction step in three groups of samples to be tested, concrete determination steps are:

[0057] (1) Take the sample to be tested that has been ground through an 80-mesh sieve, add deionized water, shake at a constant temperature of 20°C for 30 minutes after stirring, let stand for 8 hours, centrifuge at 4500rpm for 15 minutes, take the supernatant after centrifugation, filter it for testing, and dry the residue . This step extracts water-soluble mercury, mainly including HgCl 2 , HgNO 3 , HgSO 4 etc., the liquid-solid ratio is 1:10g / ml;

[0058] (2) Freeze-dry the residue from step (1) to...

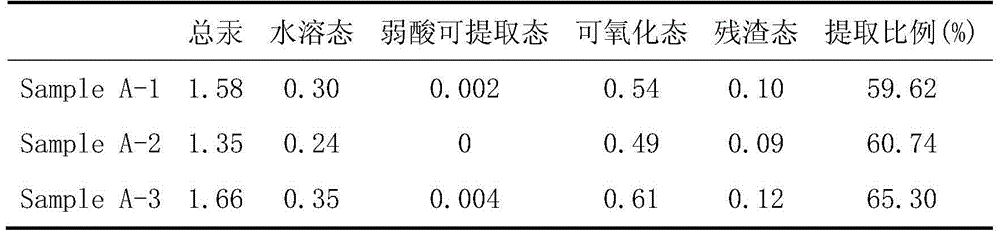

Embodiment 3

[0066] Select a wet desulfurization gypsum sample from a power plant in Zhejiang, divide it into three equal parts, each 5g, and mark it as Sample C-1, Sample C-2, and Sample C-3. At first adopt atomic fluorescence spectrophotometry to measure the content of total mercury in the sample, then use the method in the present invention to measure respectively the content of mercury in each extraction step in three groups of samples to be tested, concrete determination steps are:

[0067] (1) Take the sample to be tested that has been ground through a 70-mesh sieve, add deionized water, stir at a constant temperature of 25°C, shake for 30 minutes, let it stand for 8 hours, centrifuge at 5000rpm for 20 minutes, take the supernatant after centrifugation and filter it to be tested, the residue dry. This step extracts water-soluble mercury, mainly including HgCl 2 , HgNO 3 , HgSO 4 etc., the liquid-solid ratio is 1:6g / ml;

[0068] (2) Freeze-dry the residue from step (1) to remove m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com