Apparatus and method for measuring spline dimension of besides-star wheel

A technology of outer star wheel and spline, which is applied in the field of non-contact measurement, can solve problems such as difficult to meet fast, mass production, low detection efficiency, and gauge disputes, so as to improve measurement accuracy and detection efficiency, enhance clarity and Effect of contrast, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

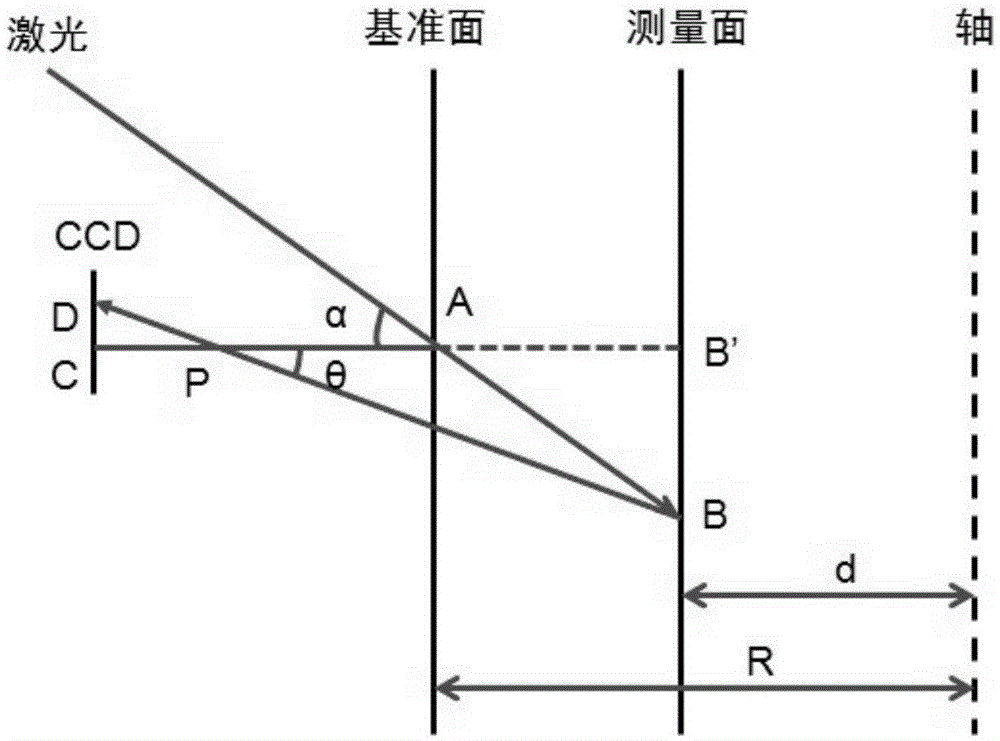

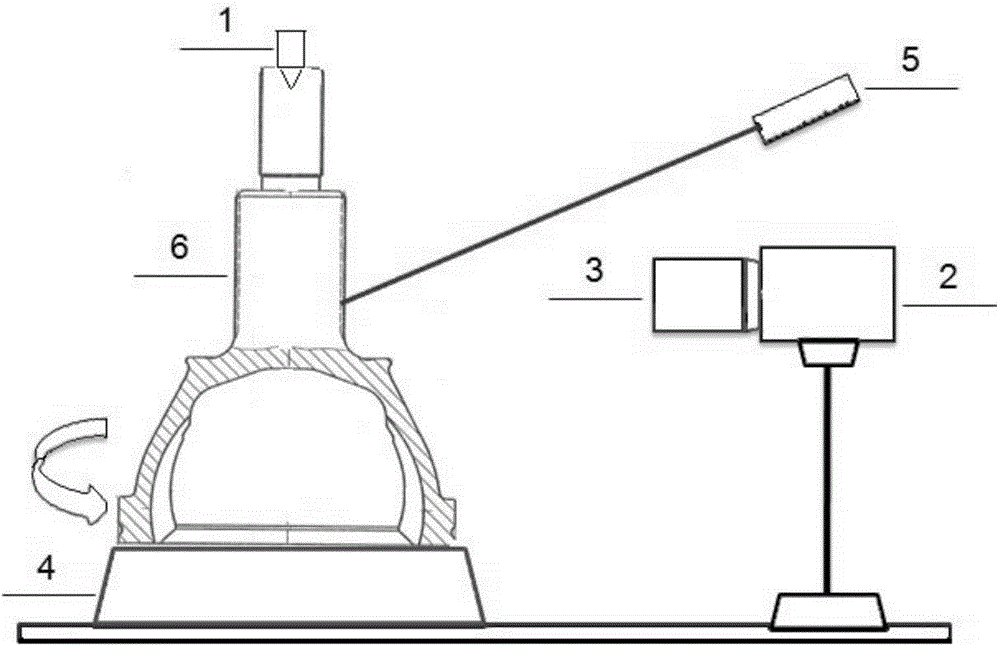

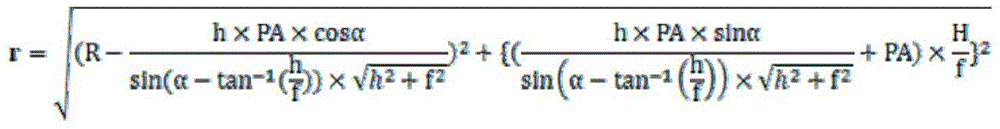

[0031] The device for measuring the spline size of the outer planet wheel provided by this embodiment is as follows: figure 2 As shown, it is made based on the triangulation method, including a laser 5, a camera 2, a lens 3 and a mechanical structure for fixing the measured object. The mechanical structure used to fix the workpiece under test includes the turntable 4 at the bottom and the thimble 1 at the top. After the thimble 1 is pressed down, the workpiece 6 under test is axially fixed. The turntable 4 is driven by a servo motor. The laser 5 selects a 20mW large divergence angle bar laser. The camera 2 selects a 5 million pixel CCD camera for use. Lens 3 is a 50mm fixed-focus lens. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com