Relative-position detection method of band-like material

A detection method and relative position technology, applied in the direction of measuring devices, electrical devices, instruments, etc., can solve the problems of low transparency, dust interference, etc., and achieve the effect of simple detection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

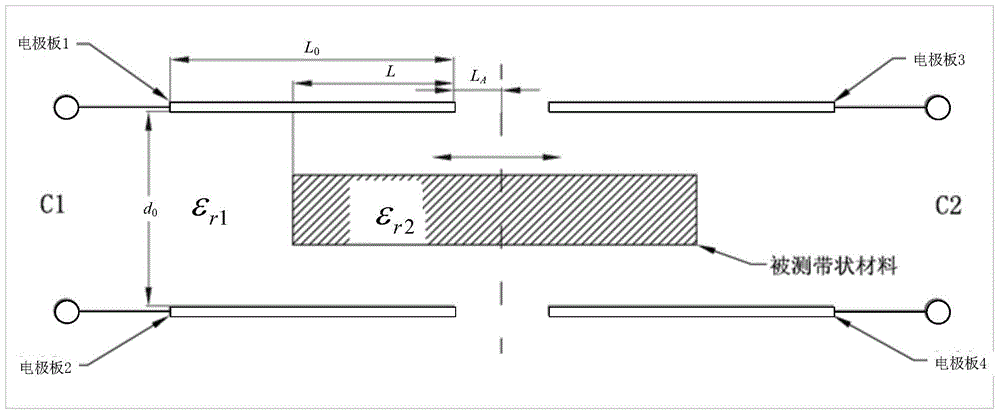

[0016] Combine below figure 1 The method of detecting the relative position of the strip-shaped material according to the present invention will be described.

[0017] Step 1: Arrange the detection structure.

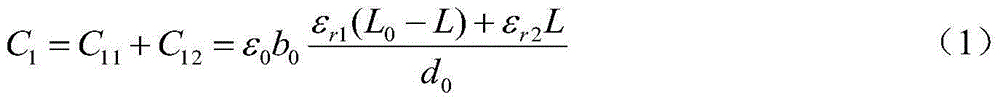

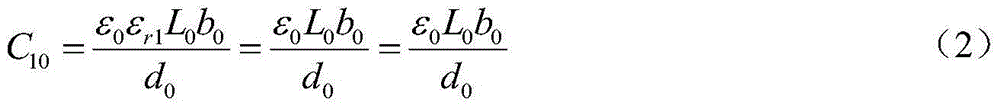

[0018] The detection mechanism consists of four parallel electrode plates of the same size and shape, such as figure 1 shown. The electrode plate 1 and the electrode plate 2 form a capacitor C1, and the electrode plate 3 and the electrode plate 4 form a capacitor C2. The capacitors C1 and C2 are respectively arranged on the left and right sides of the production line of the strip material to be tested. In the embodiment of the present invention, preferably, the two capacitors are left-right symmetrical about the vertical plane where the centerline of the production line of the strip-shaped material to be tested is located. The strip materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com