A quick-opening detachable heat preservation box

An insulation box and quick-opening technology, which is applied in the direction of heat preservation, pipeline protection, and pipeline protection through heat insulation, can solve the problems of poor external force bearing performance, easy disassembly and assembly, complex and time-consuming problems, etc., and achieve strong external force bearing performance, Not easy to crack or deform, easy to process and produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

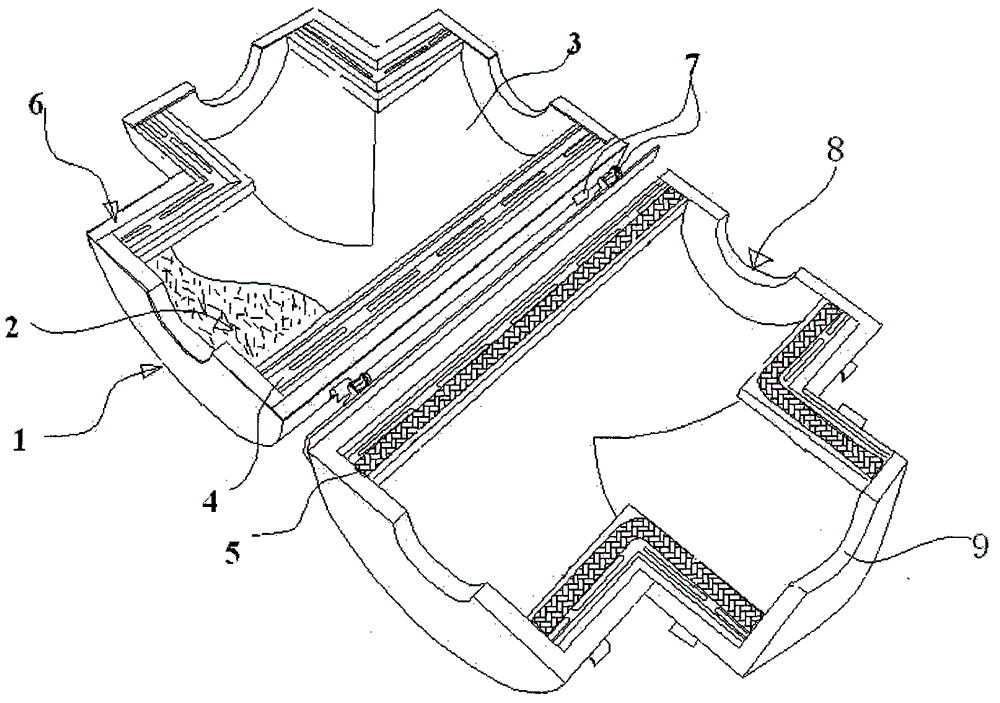

[0016] according to figure 1 The present invention is a quick-opening detachable heat preservation box, which is used for heat preservation of pipes, valves, flanges, heat exchangers and other special-shaped equipment. 1. The heat insulation layer 2 and the reflective layer 3. The split symmetrical structure is fastened by a quick-release lock 7, and the sealing support plate 4 is fixed on the butt joint surface of the split symmetrical structure.

[0017] The protective layer 1 is made of a hard composite material, the hard composite material includes a substrate and a composite reinforcing material, and the substrate is made of one of bentonite, dolomite, magnesium oxychloride, magnesium oxysulfide and magnesium phosphate The composite reinforcing material is made of one or more of glass fiber, polyester fiber, nylon fiber and natural fiber. The heat insulation layer 2 is made of a rigid foam material, which is an ultra-low density porous structure material made by using th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com