Locking device

A locking device and lock nut technology, which is applied in the direction of locking fasteners, turbine/propulsion device lubrication, threaded fasteners, etc., can solve problems such as low reliability and easy failure of locking effect, and achieve The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

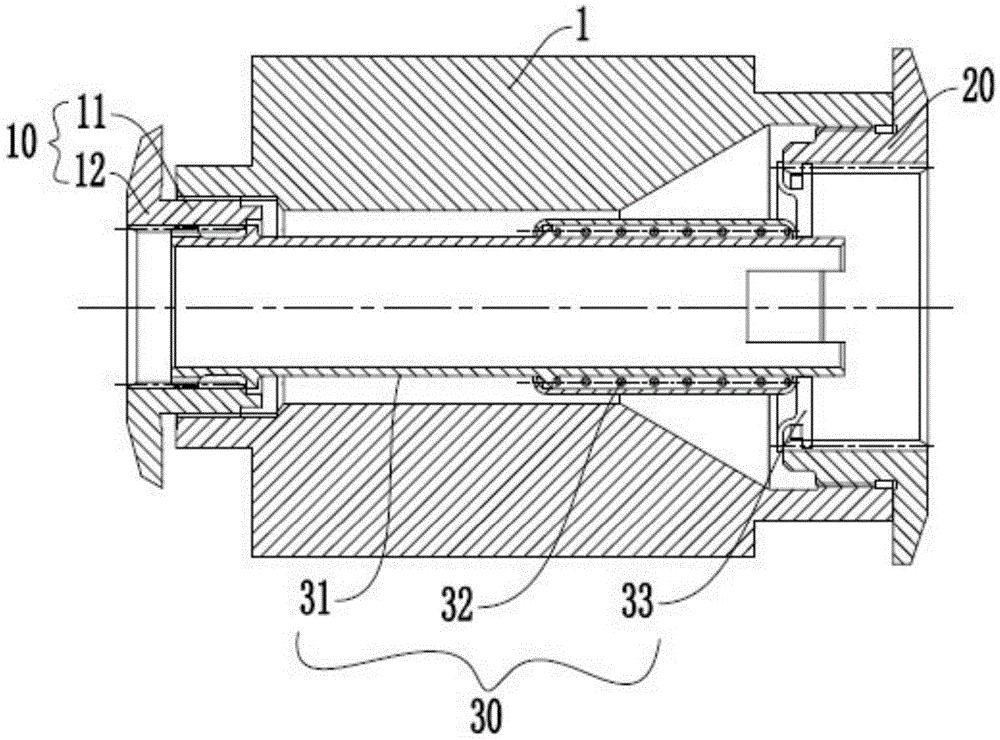

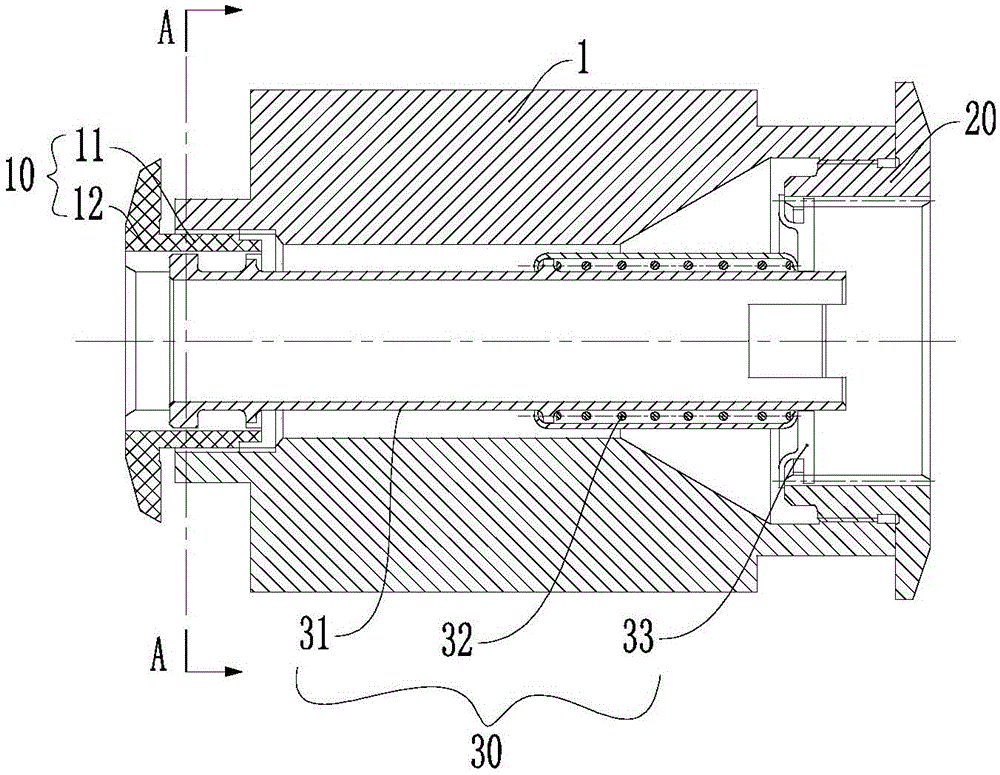

[0024] see figure 1 , the preferred embodiment of the present invention provides a locking device for locking the bearing installed on the rotor shaft 1; the locking device includes a lock nut 10, which is threadedly connected with the first end of the rotor shaft 1 for Lock the bearing installed between the lock nut 10 and the shoulder of the rotor shaft 1; the fixing part 20 is fixedly arranged on the second end of the rotor shaft 1; the self-locking assembly 30 is rigidly connected between the lock nut 10 and the fixing part 20 for fixing the lock nut 10 and the fixing piece 20 along the circumferential direction of the rotor shaft 1 . According to the locking device of the present invention, a lock nut 10 and a fixing member 20 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com