An automatic material preparation device for detonator combined mold in detonator production

A combined mode and detonator technology, applied in detonators, offensive equipment, etc., can solve the problems of prone to errors, low work efficiency, low forward rate, etc., and achieve the effects of good matching, compact device structure, and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

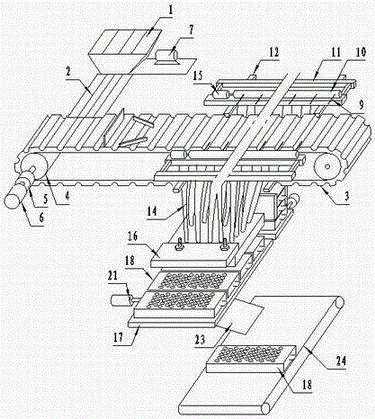

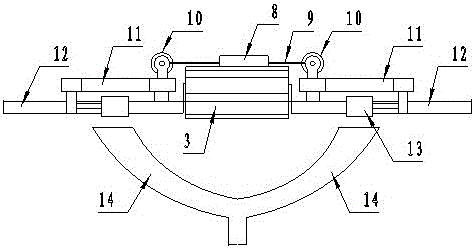

[0026] Such as figure 1 As shown, the present invention includes a tube delivery mechanism, a tube shell direction adjustment mechanism and a tube loading mechanism connected in sequence. The tube delivery mechanism is on the top of the detonator tube casing automatic discharge device, the tube casing direction adjustment mechanism is located on both sides of the tube delivery mechanism, and the tube loading mechanism is located under the tube case direction adjustment mechanism. The detonator casing automatic pipe arrangement device is arranged at the beginning of the detonator production line, and a complete production line is formed by the assembly line conveyor belt and the detonator assembly line.

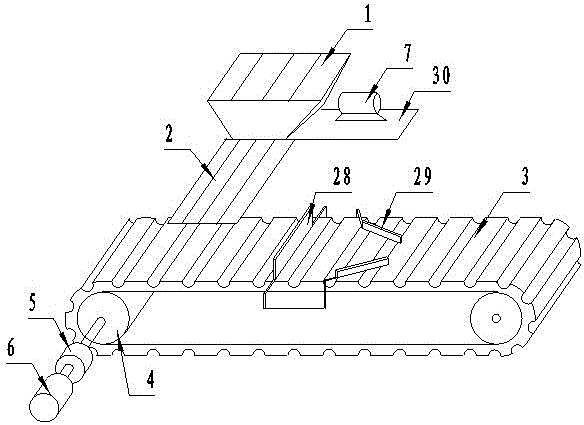

[0027] Such as figure 2 As shown, the pipe feeding mechanism includes a hopper 1, a slide plate 2, a conveyor belt 3, and a driving wheel 4 and a driving ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com