Moisturizing method and moisturizing strip for nozzle of digital printing machine

A technology of digital printing machine and moisturizing strip, applied in printing and other directions, can solve the problems of easy soiling, poor adhesion and sealing, difficult to control the amount of moisturizing liquid, etc., to achieve good surface adsorption, prevent air backflow, and good moisturizing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Moisturizing methods for nozzles of digital printing machines, including:

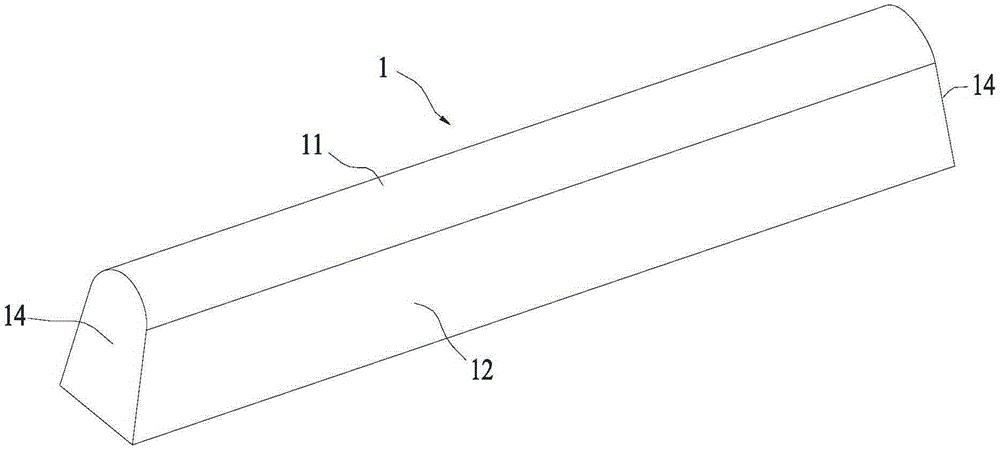

[0025] Use pad printing silicone to make moisturizing strips, and install the moisturizing strips on a horizontal platform to keep the upper surface of the moisturizing strips horizontal;

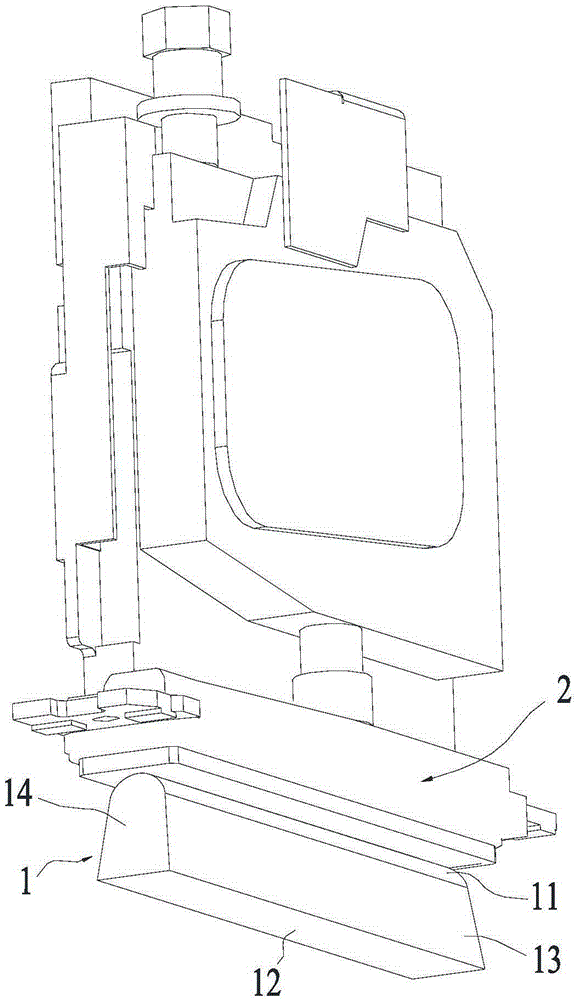

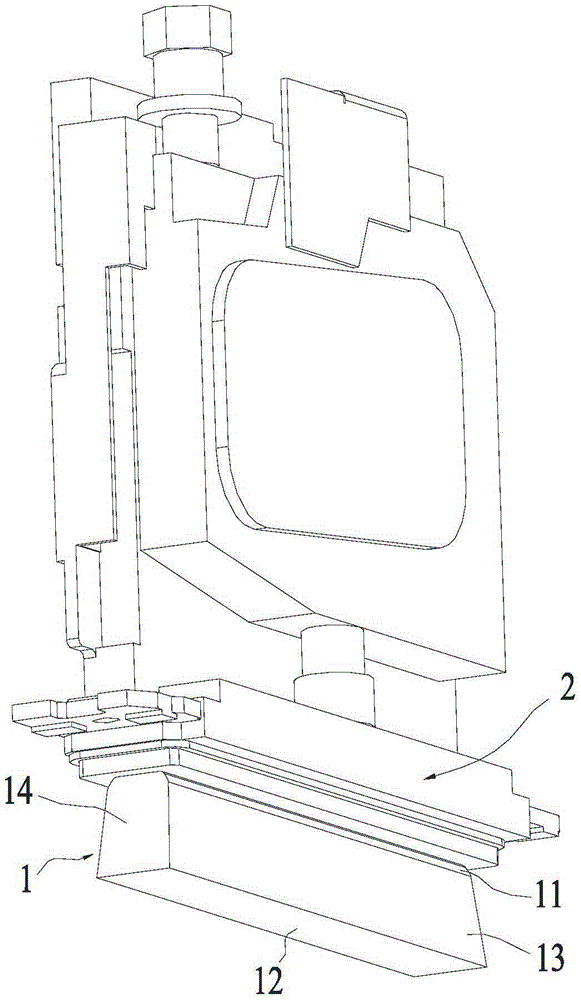

[0026] Move the nozzle that needs to be moisturized to the top of the moisturizing strip, move the nozzle down until it touches the moisturizing strip, and then reduce the speed, and press down on the moisturizing strip at a speed of 0.5mm / s~1mm / s, that is, the speed at which the nozzle presses down on the moisturizing strip is less than that of the bottom Move the nozzle to the speed of touching the moisturizing strip, then the moisturizing strip deforms elastically and squeezes away the air at the outlet of each nozzle hole on the nozzle, as shown in figure 2 As shown, when the moisturizing strip 1 is elastically deformed until the upper surface of the moisturizing strip is sealed flat with the nozzle hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com