Hot melt isolater and decorative lamp using seid isolater and its manufacturing method

A technology for spacers and decorative lamps, which is applied to the safety devices of lighting devices, lighting devices, lighting and heating equipment, etc. It can solve the problems of long solidification time of silica gel, difficult operation control, and gaps left, so as to achieve enhanced sealing and waterproofing Effect and tensile properties, avoiding fullness and possible gaps, and preventing mutual contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

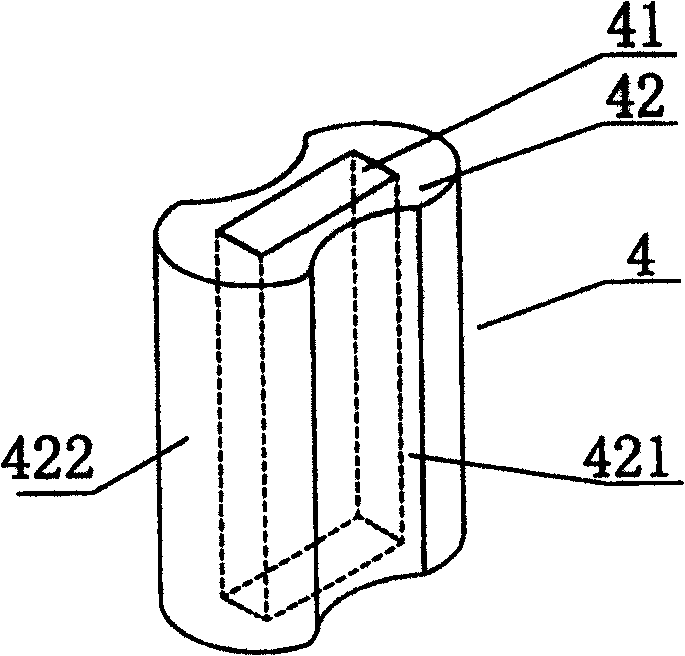

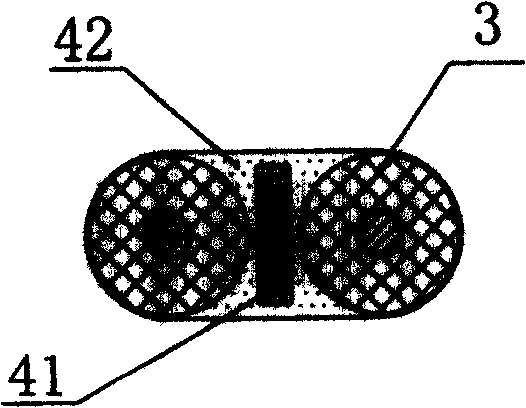

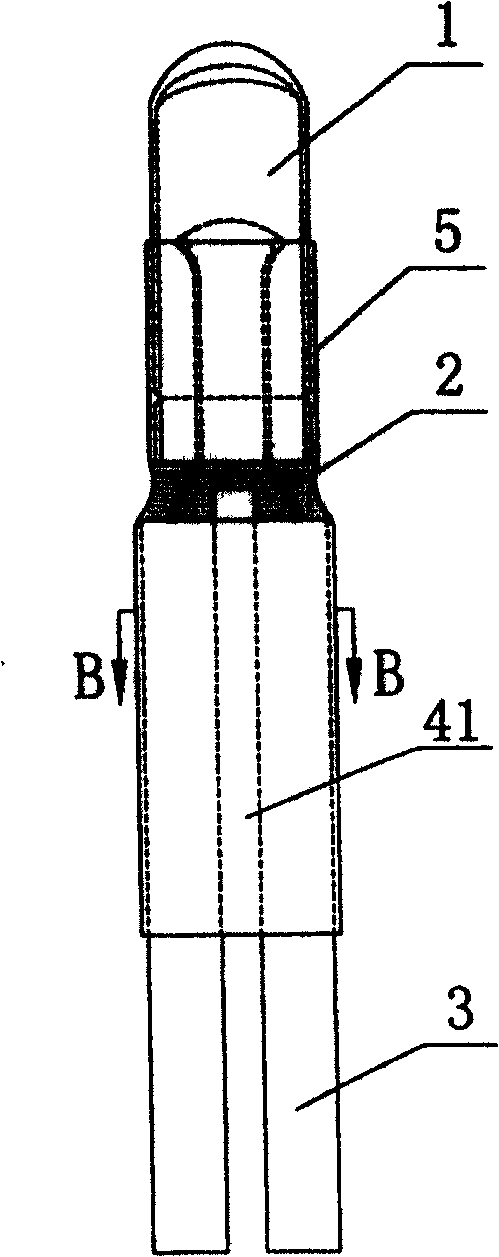

[0020] Such as figure 1 and Figure 4 As shown, a decorative lamp hot-melt spacer of the present invention includes a spacer 4 arranged between the two lamp pins 2 of the bulb 1 and between the two connecting wires 3, and the feature is that the spacer 4 includes a spacer 41 And the hot-melt layer 42 coated on the outside of the separator 41 . In order to further improve the good isolation between the two lamp pins 2 and the connecting wires 3 of the decorative lamp of the present invention, avoid the two lamp pins 2 and the connecting wires 3 from being in contact with each other and cause a short circuit, and at the same time clamp the spacer 4 conveniently and quickly to improve the isolation between the two connecting wires. 3 The stability of the clamping spacer 4, such as figure 1 As shown, the outer surfaces of both sides of the hot-melt layer 42 covering the separator 41 are symmetrically provided with vertical recesses 421 for accommodating wires. In order to incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com