Multi-station indexing mechanism

An indexing mechanism and multi-station technology, applied in metal processing machinery parts, manufacturing tools, precision positioning equipment, etc., to achieve accurate positioning, high degree of automation, and improve the effect of processing positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

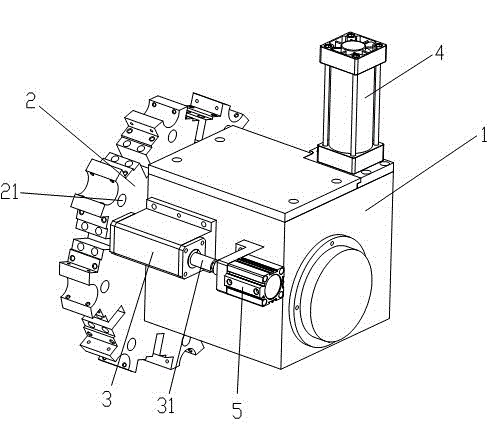

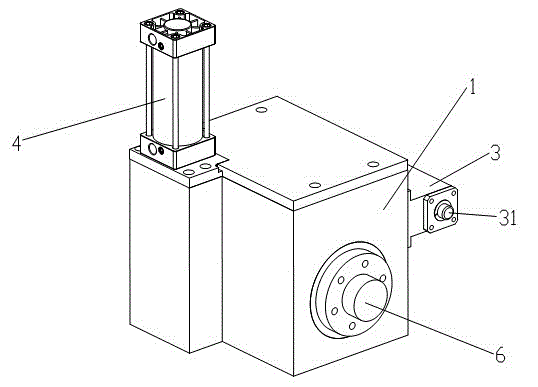

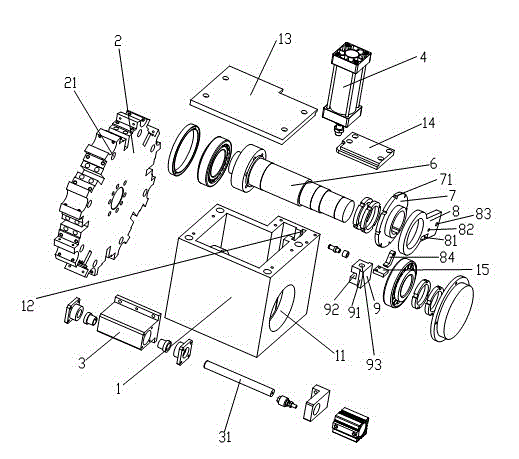

[0032]

[0033] Embodiment of the present invention is illustrated below in conjunction with accompanying drawing:

[0034] see image 3 As shown, a multi-station indexing mechanism is provided, including a central shaft 6, one end of which is fixedly connected with an indexing turntable 2, and the central shaft 6 is arranged on both side walls of a box body 1, A corner of the box body 1 is provided with a guide groove 12, and the box body 1 is provided with an upper cover plate 13 and a corner cover plate 14, and the guide groove 12 is slidably matched with a slider 9, and the slider 9 and the The cylinder 4 that is arranged on the upper plane of the box body 1, that is, the corner cover plate 14, is threaded; the cylinder 4 drives the slide block 9 to slide along the guide groove 12; To drive the indexing turntable 2 to rotate synchronously; the central shaft 6 is also provided with a movable swing arm 8 to cooperate with the indexing toothed disk 7, and the movable swing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com