Warning device for preventing welding missing and welding lack during carbon dioxide welding

A carbon dioxide and alarm device technology, applied in auxiliary devices, measuring devices, electrical devices, etc., can solve the problem of wasting time and achieve the effect of avoiding missing welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

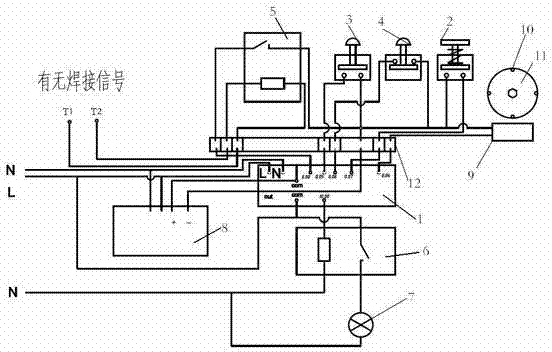

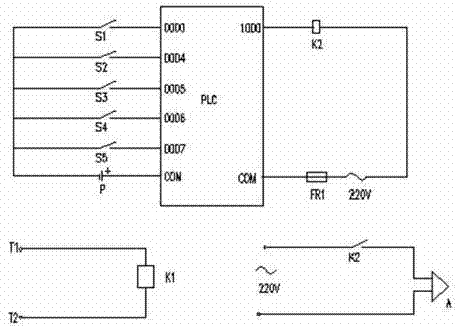

[0013] Example: see figure 1 , figure 2 .

[0014] An alarm device for preventing missing welding and less welding in carbon dioxide welding, comprising a reset switch 2, a first stroke switch 3, a second stroke switch 4, a first intermediate relay 5, a second intermediate relay 6, an audible and visual alarm 7, and a welding length Detection signal device, PLC1, switching power supply 8; reset switch 2, first travel switch 3, second travel switch 4, first intermediate relay 5, second intermediate relay 6, welding length detection signal device, switching power supply 8 and PLC1 respectively Electrically connected, the first intermediate relay 5 is electrically connected to the welding machine gas valve control terminal coil, and the second intermediate relay 6 is electrically connected to the sound and light alarm 7.

[0015] The welding length detection signal device includes a magnetic switch 9 and a matching magnetic mounting plate 11. The magnetic mounting plate 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com