Pneumatic fresh lotus plumule removing machine

A lotus seed and pneumatic technology, which is applied in the fields of fruit core removal device, food science, and application, can solve the problems of unstable product quality, high loss rate of lotus seeds, non-compliance, etc., to reduce manual labor intensity, improve core removal efficiency, The effect of improving the core removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

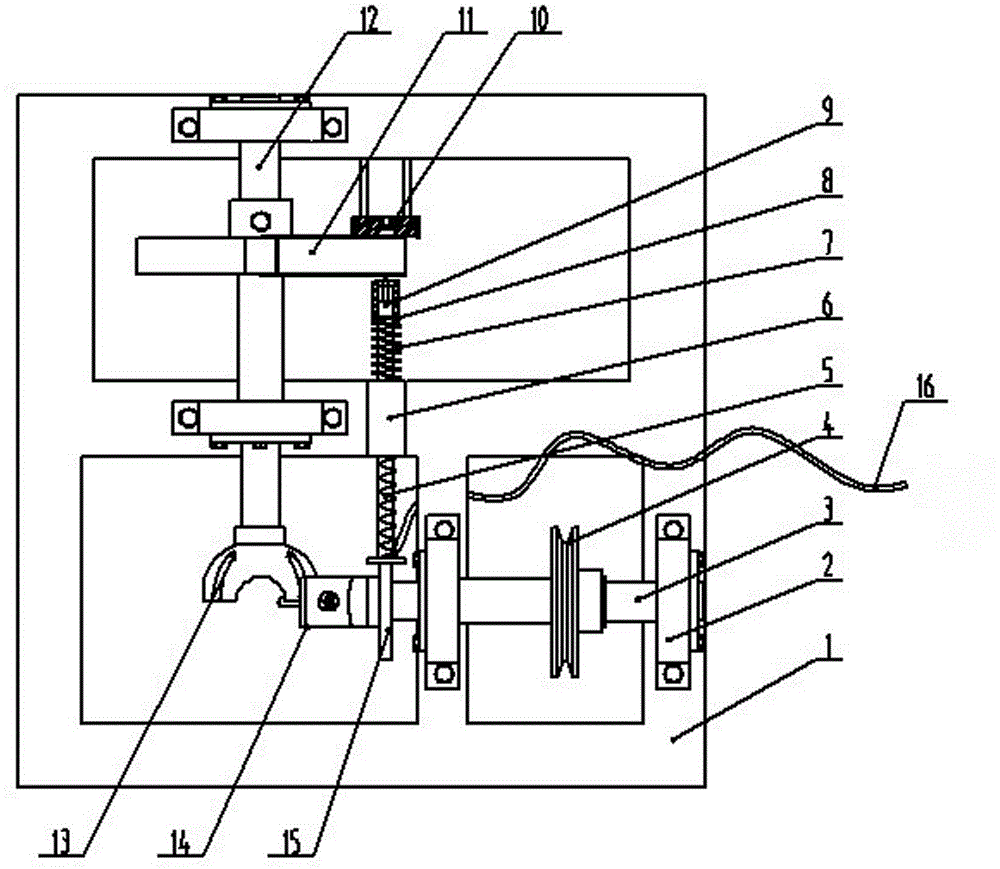

[0011] A pneumatic coring machine for fresh lotus seeds, comprising a frame 1, a main shaft 3, a bearing 2, a driven shaft 12, a pulley 4, and a motor 18, the motor 18 is connected to the pulley 4 on the main shaft 3 through a belt 17, and its characteristic is that the main shaft One end of 1 is equipped with a cam 15 and a sheave pick 14, and the sheave pick 14 is connected with the sheave 13 on the driven shaft 12, and the drum 11 is installed on the driven shaft 12, and the drum 11 rotates with the driven shaft 12, and the drum On the side of 11, there are evenly distributed material troughs 23, and a feed hopper 19 is installed above the drum 11; the cam 15 on the main shaft 3 is in contact with the through-heart transmission rod 5, and the through-heart transmission rod 5 is arranged in the guide sleeve 6, and the spring 7 Set on the through-core transmission rod 5, the end of the through-center transmission rod 5 is equipped with a hollow die 9 and a through-core die 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com