Pounding end, hammering method and welded joint using the method

A technology of tipping and hammering, applied in the direction of welding/welding/cutting items, welding equipment, welding equipment, etc., can solve problems such as fatigue notch, fatigue fracture, etc., and achieve the effect of improving fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

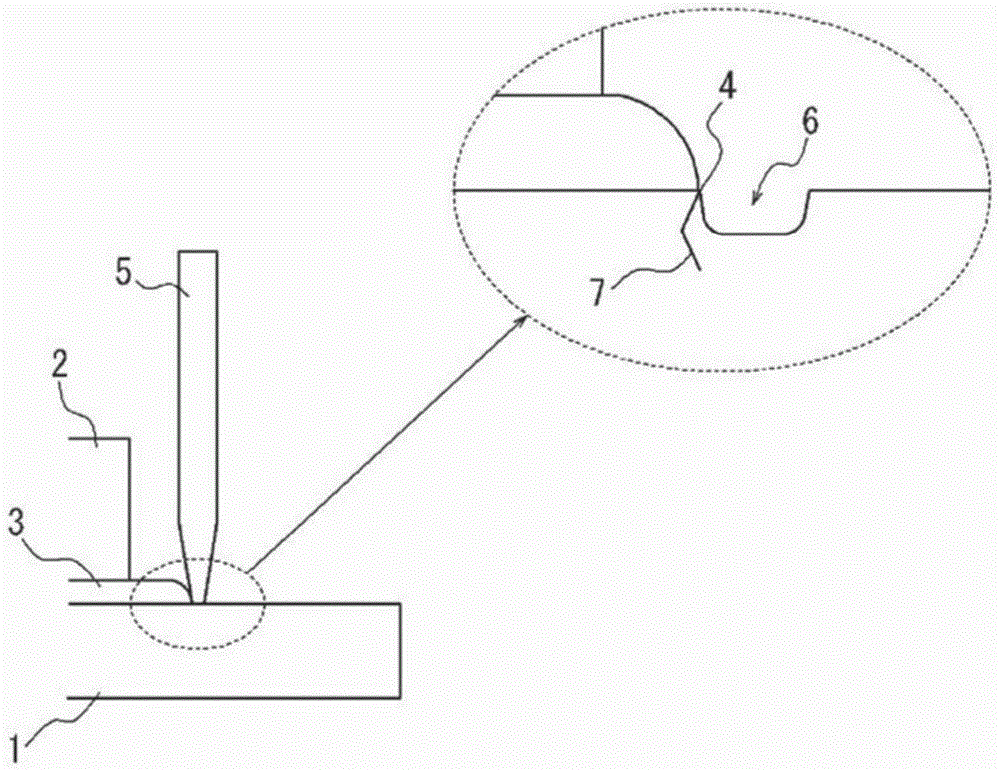

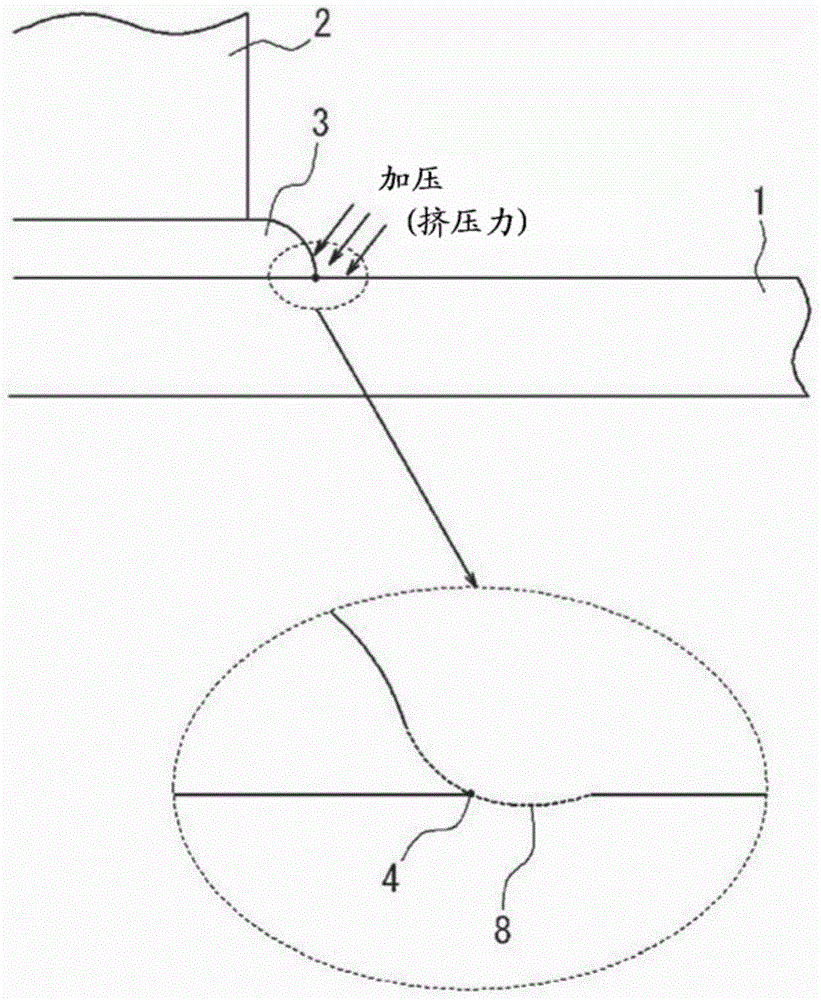

Method used

Image

Examples

example 1)

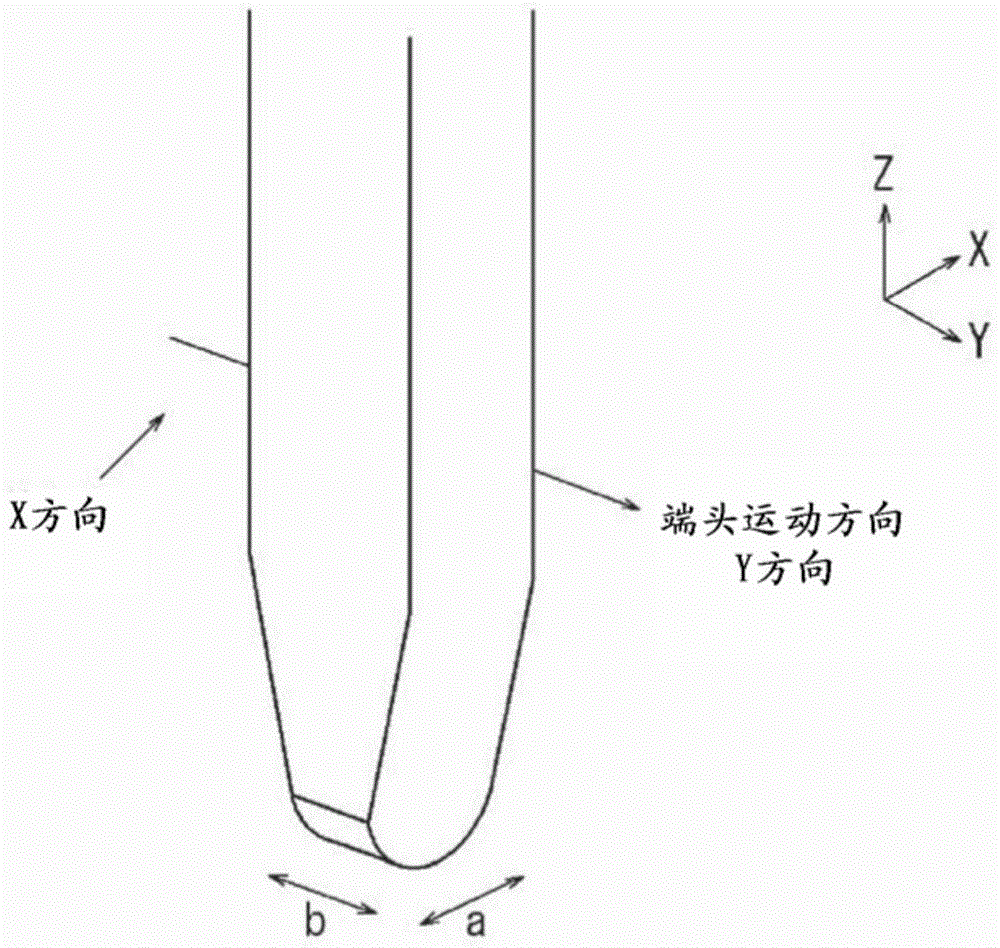

[0082] The following striking tips were prepared: with a radius of curvature of 4.5 mm at the top in the XZ section (section orthogonal to the direction of movement of the tip) and with a radius of curvature in the YZ section (section in the direction of movement of the tip) 5 mm in length. The following striking tip is also prepared: in the XZ section (section orthogonal to the direction of movement of the tip) having an elliptical arc shape whose major radius is perpendicular to the direction of movement and striking tip The axis directions are both oriented parallel - the major radius is 6 mm and the minor radius is 3 mm, and has a length of 9 mm in the YZ section (the section in the direction of motion of the tip). A hemispherical striking tip having a distal end having a radius of curvature of 1.5 mm was also prepared. Such as Figure 6A As shown, the welding is performed by performing welding (welding line Protective gas 100% CO 2 , Welding current 240 amps - weldin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com