Pay-off frame for flight stringing

A pay-off frame and stringing technology, applied in the field of pay-off racks, can solve problems such as unsuitable construction parties, increased weight, and complex structures, and achieve the effects of light overall weight, simple connection devices, and accurate flight routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

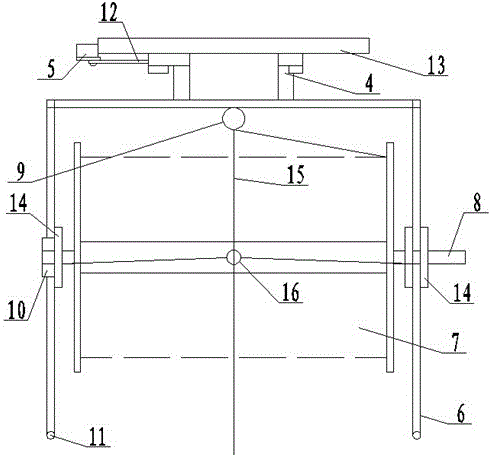

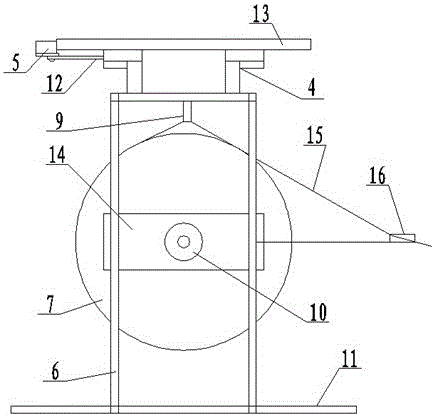

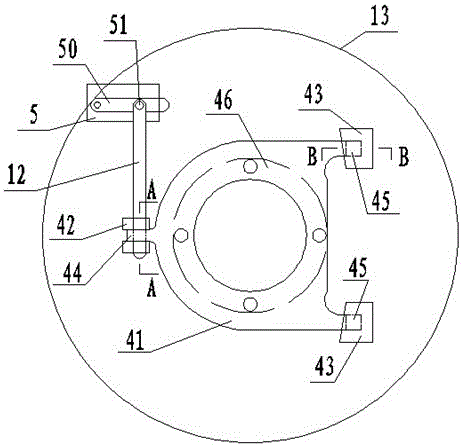

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] Such as figure 1 , 2 As shown, the main body of the pay-off frame for aerial stringing of the present invention is a frame made of light and high-strength pipes (such as carbon pipes), and a bobbin 7 is installed in the frame, and a Dyneema rope 15 is wound around the bobbin 7 . The aircraft may be a multi-axis multi-rotor aircraft. The aircraft chassis 13 is provided with a control device for controlling the flight of the aircraft. The control device can receive the signal from the remote control device to control the flight of the aircraft, and can also realize the automatic flight control of the aircraft according to the signal of the navigator.

[0023] The following of the aircraft chassis 13 is connected to the pay-off rack 6 through a connecting device 4, so that the pay-off rack 6 can rotate freely and can be separated from the aircraft chass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com