Diaphragm capsule valve stroke test device and using method thereof

A test device and bellows valve technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as low efficiency, difficulty in ensuring constant temperature of the test environment, complicated process, etc., and achieve reduction Small impact, improved test accuracy and test efficiency, large economic and social value effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

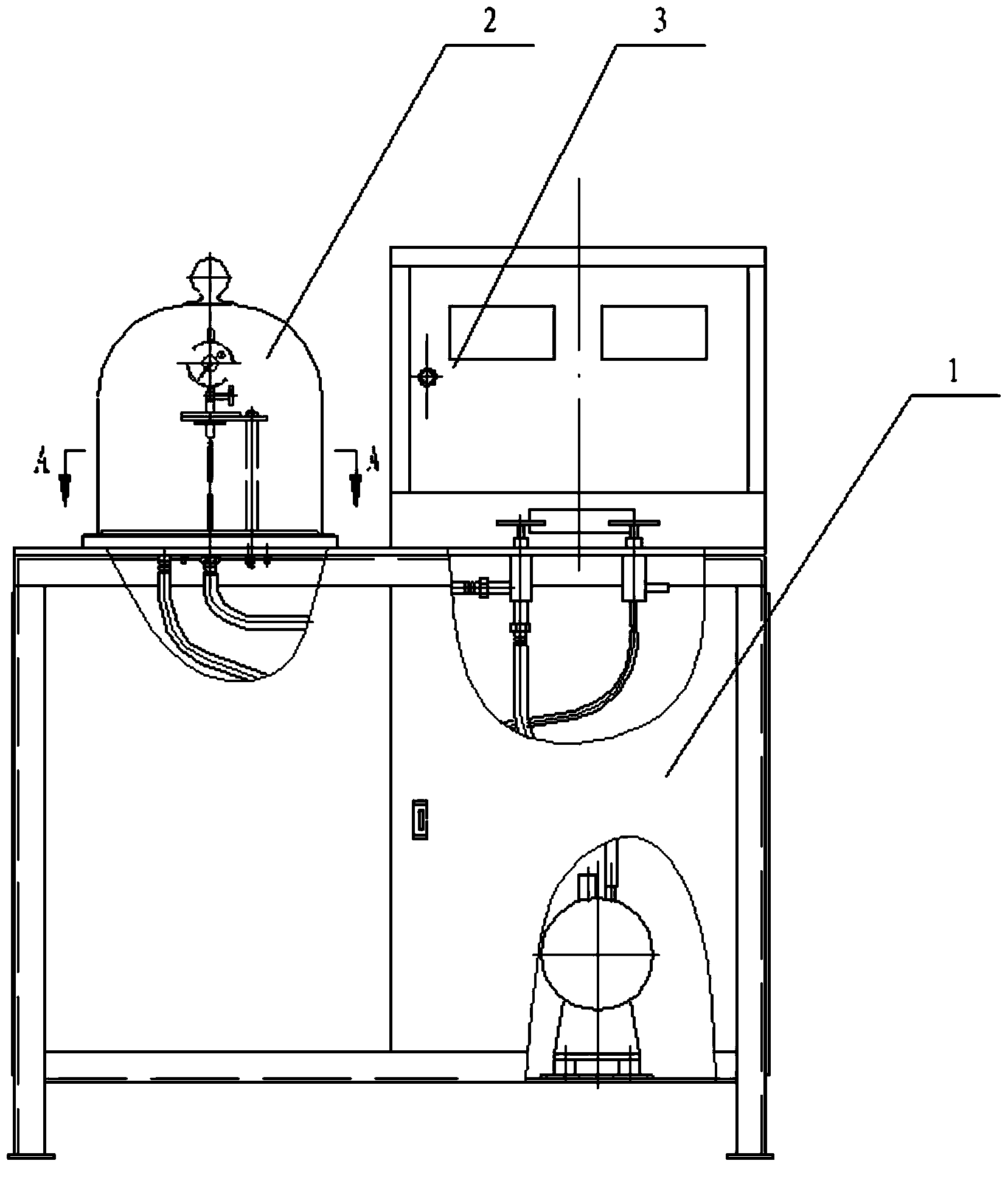

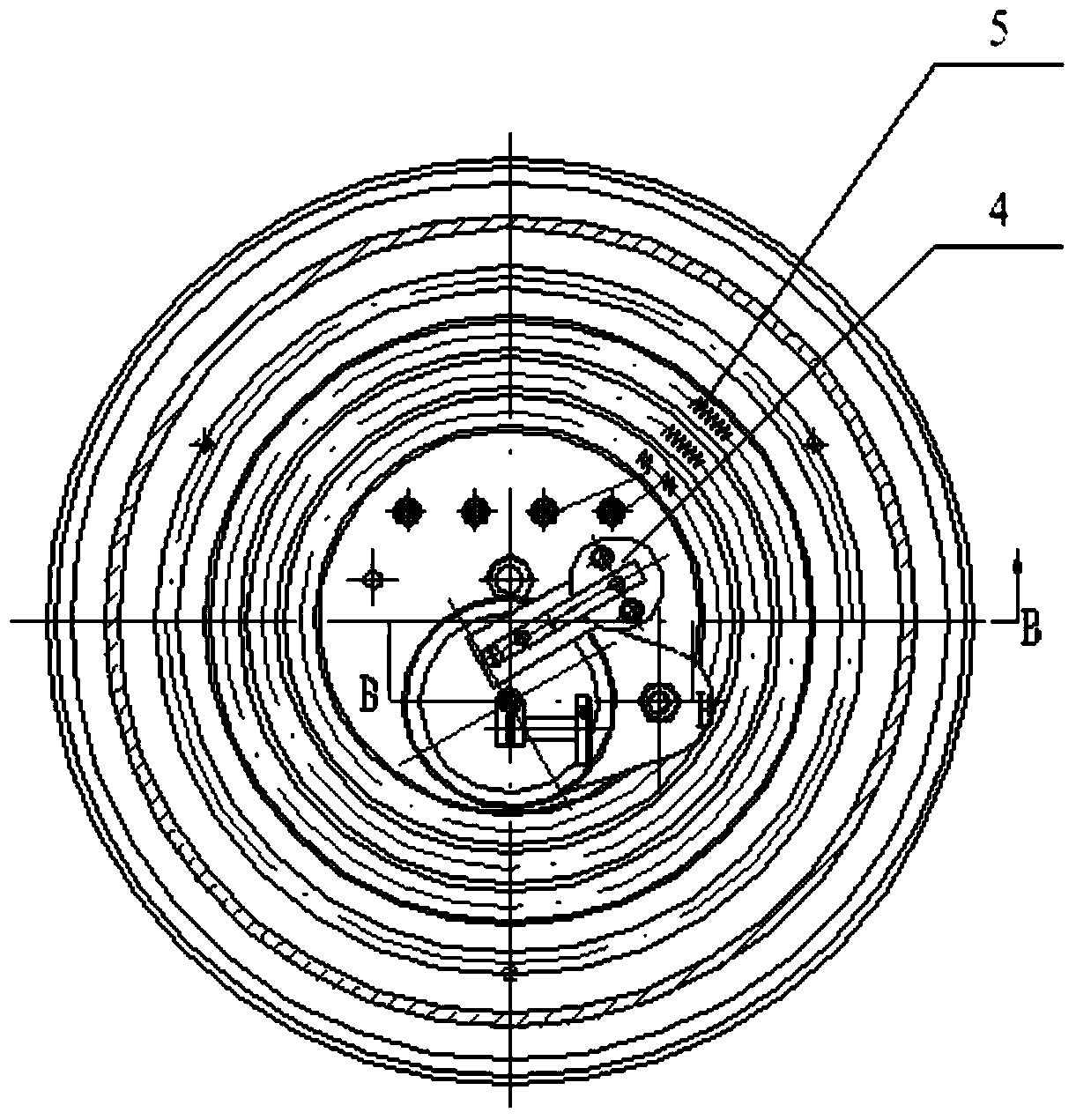

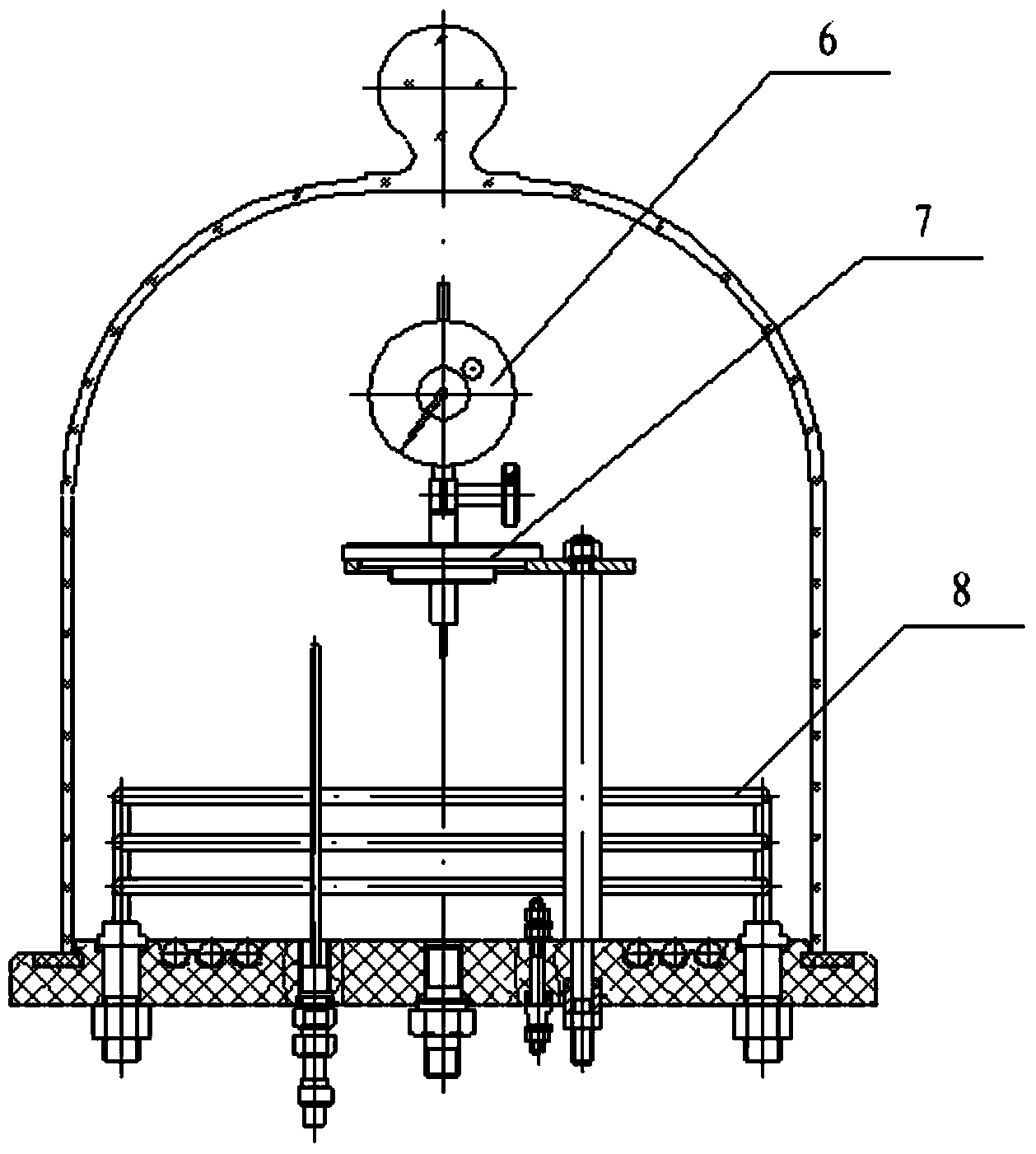

[0030] This embodiment provides a bellows valve travel test device, the bellows valve travel test device consists of the following: workbench 1, vacuum chamber 2 and instrument box 3, vibrator 4, heating resistance wire 5, dial indicator 6 , measuring tool 7, evaporator 8, vacuum pump 9, manual switch valve 10, automatic switch valve 11, automatic air release valve 12, manual air release valve 13, condenser 14, refrigeration compressor 15, absolute pressure sensor 16, temperature measurement sensor 17;

[0031] The vacuum chamber 2 includes a bell-type structure and a lower chassis, the bell-type structure is located above the lower chassis, and the lower chassis is provided with a small hole structure for installing measuring tools 7, sensors, conductive terminals and for The intake and exhaust of the vacuum chamber, the vacuum chamber 2 and the instrument box 3 are fixedly installed on the workbench 1;

[0032] The vacuum pump 9, the refrigeration compressor 15 and the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com