Tertiary premix energy-saving gas distribution chamber for stove

A gas distribution chamber and stove technology, which is applied in the field of tertiary premixed energy-saving air distribution chambers for stoves, can solve the problems of air pollution, wasted gas, unreasonable air premixing, etc., so as to reduce pollution, save energy, and save gas. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

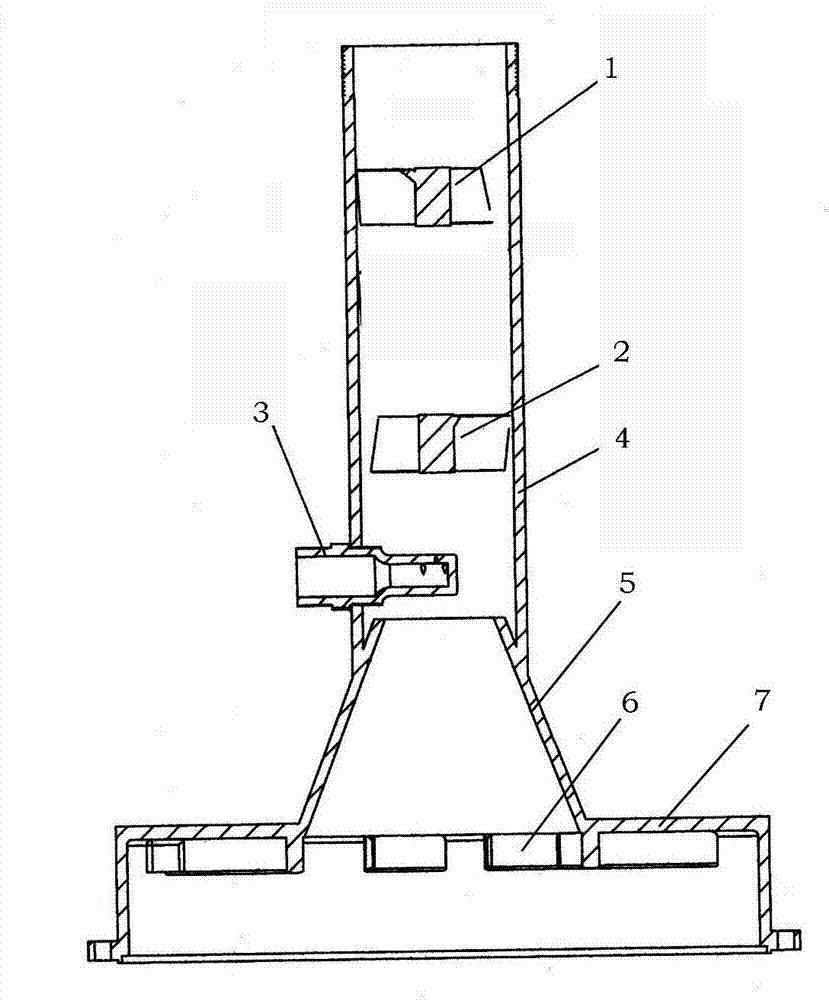

[0020] Such as figure 1 As shown, the three-time premixed energy-saving gas distribution chamber for the stove of the present invention has the following structure: a first fan 1 and a second fan 2 are arranged in the fan duct 4, and the distance between the first fan 1 and the second fan 2 is 115 -125mm, the direction of the fan blades of the first fan 1 and the second fan 2 is arranged in symmetrical opposite directions, the lower end of the fan pipe 4 is connected with the conical cylinder 5, the diameter of the upper end of the conical cylinder 5 is smaller than the diameter of the lower end, and the upper end of the conical cylinder 5 5-20 millimeters are arranged in the blower duct 4, and the position of 10-50 millimeter of the blower duct 4 bottoms apart from the conical barrel is provided with a round hole, and the gas nozzle 3 is connected in the round hole.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com