Method of verifying reasonable working resistance of working face hydraulic support

A working resistance and hydraulic support technology, which is applied to mine roof supports, earth-moving drilling, mining equipment, etc., can solve the problem of lack of a reasonable support working resistance verification and setting method, lack of working face roof control effect standards, and lack of roof control. performance standards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

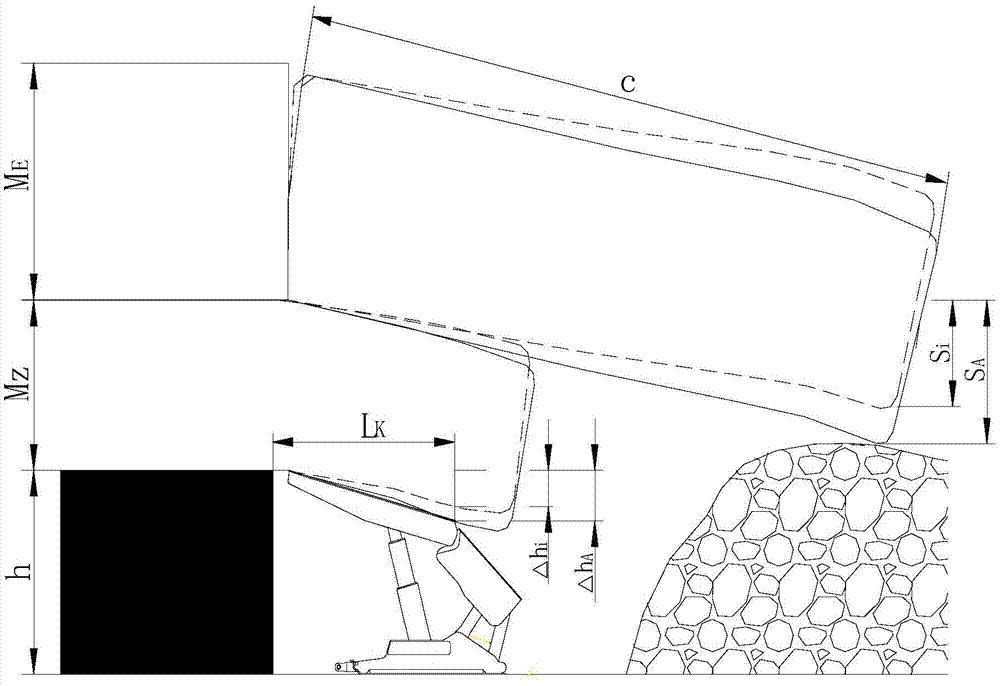

[0056] Taking the 22305 fully mechanized mining face of a certain mine as an example in conjunction with the accompanying drawings, describe in detail the concrete steps that the present invention implements:

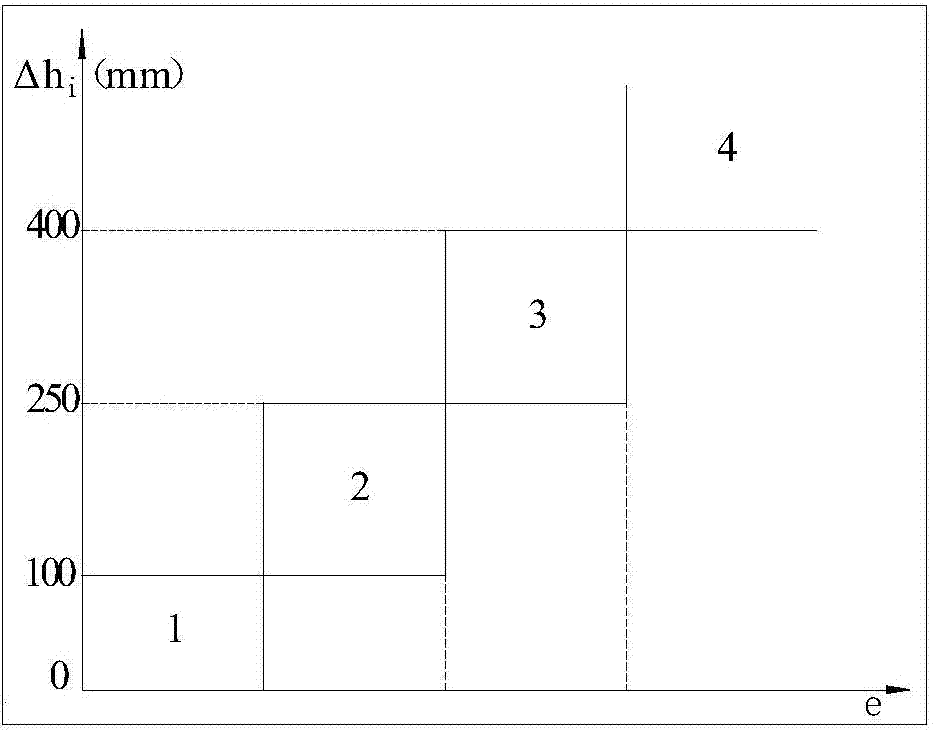

[0057] During the normal advancement of 177m in the 22305 fully mechanized mining face, the working face experienced 9 to 10 roof cycles to press. Select 5 hydraulic supports of 30#, 60#, 80#, 100#, and 120# in the working face as the monitoring objects of working resistance. According to the mine pressure monitoring parameters, adopt the "four-one rule" to approve the supports of the 22305 fully mechanized mining face that have been mined Reasonable working resistance.

[0058] 1) Calculation of the required resistance value for the reasonable working resistance of the support on the working face

[0059] (1) Support rated working resistance p

[0060] The support used in the 22305 fully mechanized mining face is a two-column shielded support with a rated working res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com