Preparation method of pH color-changing fabric

A technology of fabric and pH value, which is applied in dyeing, textiles and papermaking, etc., can solve the problems of limited application research, and achieve the effect of simple process, good rubbing fastness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a pH-value color-changing fabric, the steps are as follows:

[0027] (1) Prepare alizarin dye (Sinopharm Chemical Reagent Co., Ltd.) solution with distilled water, and then use a pipette to accurately suck the specified amount of dye solution into a clean dyeing cup to make up the required amount of water.

[0028] (2) After the dye bath is prepared, squeeze the bleached cotton cloth that has been wetted in water and put it into the alizarin dye bath to start dyeing. The amount of dye is 0.5% (owf), and the bath ratio is 50:1.

[0029] (3) Dyeing process: use a constant temperature oscillator in a water bath to dye cotton fabrics. The fabrics are dyed at 40°C. After reaching 90°C, they are dyed for 30 minutes and then cooled to room temperature.

[0030] (4) After dyeing, after washing and soaping, place the dyed fabric in an electric heating constant temperature blast drying oven to dry.

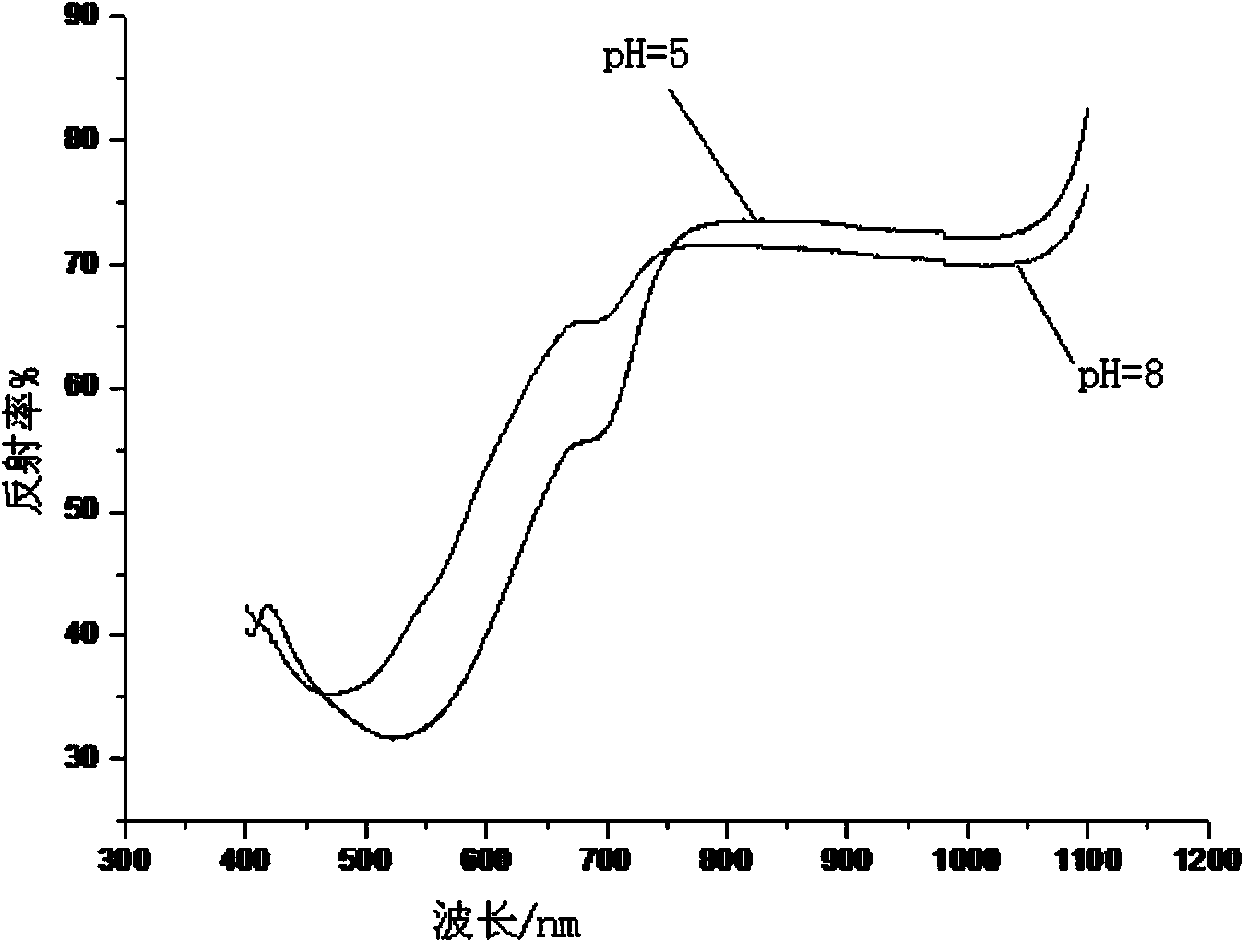

[0031] (5) In order to characterize the acid color rendering of al...

Embodiment 2

[0034] A method for preparing a pH-value color-changing fabric, the steps are as follows:

[0035] (1) Prepare the Congo red dye (China Yuanhang Reagent Factory Shanghai) solution with distilled water, and then use a pipette to accurately suck the specified amount of dye solution into a clean dyeing cup to make up the required amount of water.

[0036] (2) After the dye bath is prepared, squeeze the bleached cotton cloth that has been wetted in water and put it into the Congo red dye bath to start dyeing. The amount of dye is 0.5% (owf), and the bath ratio is 50:1.

[0037] (3) Dyeing process: use a constant temperature oscillator in a water bath to dye cotton fabrics. The fabrics are dyed at 40°C. After reaching 90°C, they are kept and dyed for 30 minutes and then cooled to room temperature.

[0038] (4) After dyeing, after washing and soaping, place the dyed fabric in an electric heating constant temperature blast drying oven to dry.

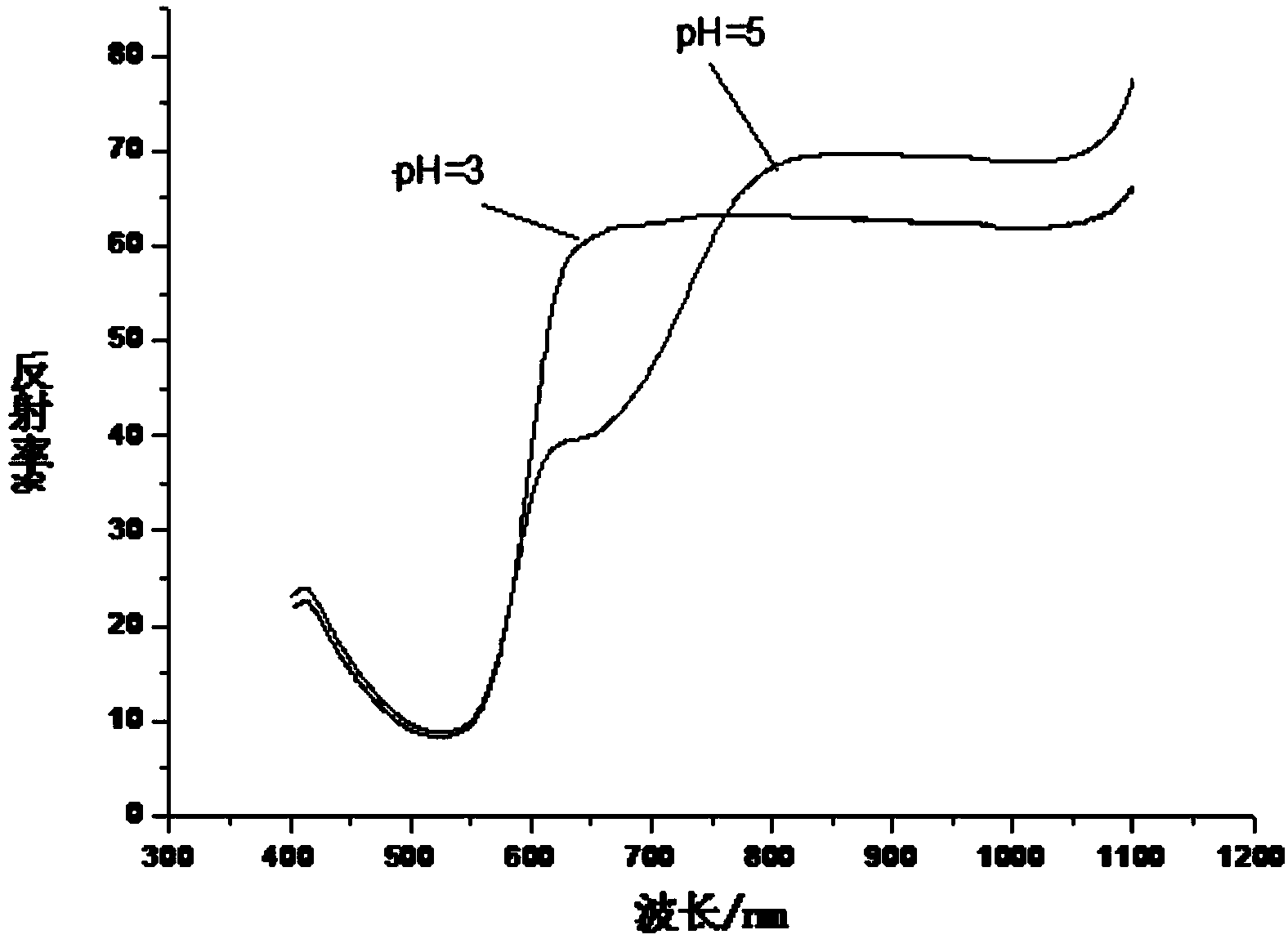

[0039] (5) In order to characterize the acid col...

Embodiment 3

[0042] A method for preparing a pH-value color-changing fabric, the steps are as follows:

[0043] (1) Prepare brilliant yellow dye (Sinopharm Chemical Reagent Co., Ltd.) solution with distilled water, and then use a pipette to accurately suck the specified amount of dye solution into a clean dyeing cup to make up the required amount of water.

[0044] (2) After the dyeing bath is prepared, squeeze the bleached cotton cloth that has been wetted in water and put it into the brilliant yellow dyeing bath to start dyeing. The amount of dye is 0.5% (owf), and the bath ratio is 50:1.

[0045] (3) Dyeing process: use a constant temperature oscillator in a water bath to dye cotton fabrics. The fabrics are dyed at 40°C. After reaching 90°C, they are dyed for 30 minutes and then cooled to room temperature.

[0046] (4) After dyeing, after washing and soaping, place the dyed fabric in an electric heating constant temperature blast drying oven to dry.

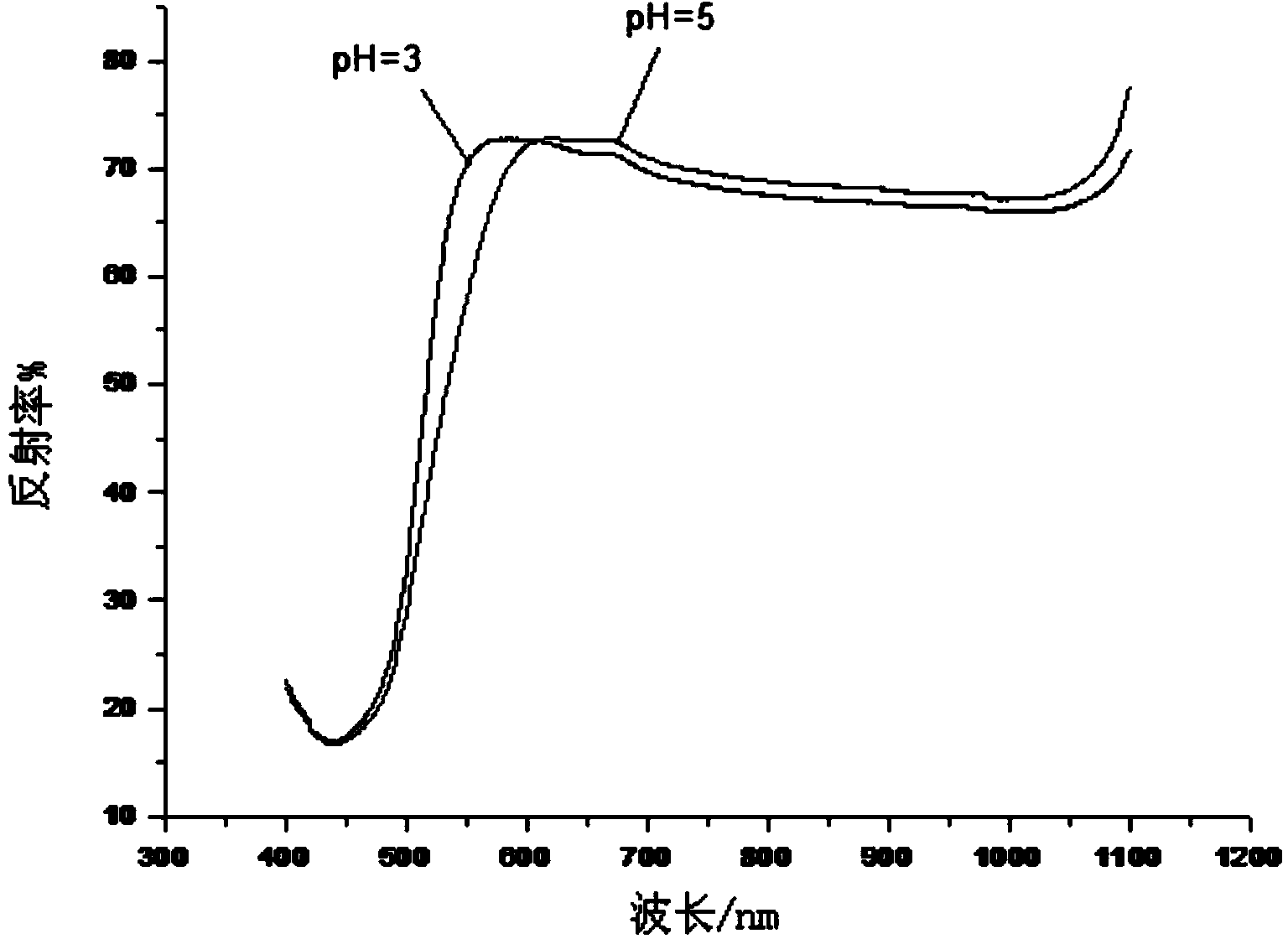

[0047] (5) In order to characterize the acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com