Preparation method of bionic gecko adhesive tape

A technology of tape and gecko, applied in the field of preparation of imitation gecko foot bristles, can solve the problems of high cost, difficult demoulding, complicated operation, etc., and achieve the effects of low cost, simple operation and controllable experimental parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0028] Specific embodiment 1: In this embodiment, ZnO / PDMS composite imitation gecko foot microarray is prepared according to the following steps:

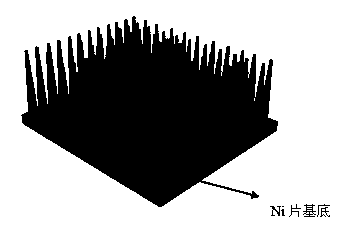

[0029] Step 1. Preparation of ZnO microarrays by solution chemistry

[0030] The Ni metal sheet was polished, ultrasonically cleaned with absolute ethanol and distilled water, and dried in an oven at 300 °C. Suspend the dried metal sheet in 50-1000mL by 0.02-0.5M Zn (NO 3 ) 2 and 0.5-3M NH 3 ·H 2 In the mixed solution prepared by O, react at 50-100°C for 10-30h. During the reaction, keep stirring the solution slightly. The metal sheet in the solution is taken out, rinsed with water repeatedly, and dried to obtain a ZnO one-dimensional nano-array.

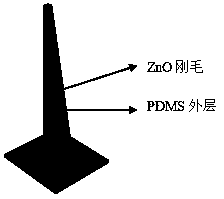

[0031] Step 2. Preparation of ZnO / PDMS composite microarray

[0032] Immerse the ZnO array in the above steps in a chloroform solution of 0.01-10% (w / w) polydimethylsiloxane (PDMS), take it out after 0.2-2h, and store it at a temperature of 50-100°C Curing 1-24h.

specific Embodiment approach 2

[0033] Specific embodiment two: this embodiment prepares imitation gecko foot microarray according to the following steps:

[0034] Step 1. Preparation of ZnO microarrays by solution chemistry

[0035] The Ni metal sheet was polished, ultrasonically cleaned with absolute ethanol and distilled water, and dried in an oven at 300 ° C, and prepared with 45 mM Zn (NO 3 ) 2 and 0.1M NH 3 ·H 2 O mixed solution 300mL. Suspend the dried metal pieces in the solution and react at 60°C for 6 hours. During the reaction, the solution is constantly stirred slightly. The metal sheet in the solution is taken out, rinsed with water repeatedly, and dried to obtain a ZnO one-dimensional nano-array.

[0036] Step 2. Preparation of ZnO / PDMS composite microarray

[0037] The ZnO array in the above steps was immersed in a 2% (w / w) polydimethylsiloxane (PDMS) chloroform solution, taken out after 0.5h, and cured at a temperature of 90°C for 1h.

[0038] The small area of the imitation gecko foot...

specific Embodiment approach 3

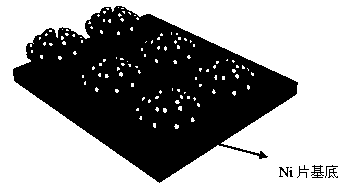

[0039] Specific embodiment three: this embodiment prepares imitation gecko foot microarray according to the following steps:

[0040] Step 1. Preparation of ZnO microarrays by solution chemistry

[0041] The Ni metal sheet was polished, ultrasonically cleaned with absolute ethanol and distilled water, and dried in an oven at 300°C, and prepared with 0.1M Zn (NO 3 ) 2 and 1.2M NH 3 ·H 2 O mixed solution 300mL. Suspend the dried metal pieces in the solution and react at 70°C for 24 hours. During the reaction, the solution is constantly stirred slightly. The metal sheet in the solution is taken out, rinsed with water repeatedly, and dried to obtain a ZnO one-dimensional nano-array.

[0042] Step 2. Preparation of ZnO / PDMS composite microarray

[0043] The ZnO array in the above steps was immersed in a 2% (w / w) polydimethylsiloxane (PDMS) chloroform solution, taken out after 0.2-2h, and cured at a temperature of 90°C for 1h.

[0044] The small area of the imitation ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com