Photodegradable nanometer polymer coated fertilizer and preparation method thereof

A fertilizer and coating technology, applied in the direction of fertilizer mixture, fertilization device, application, etc., to achieve high degradation efficiency, realize cyclic development, and reduce accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

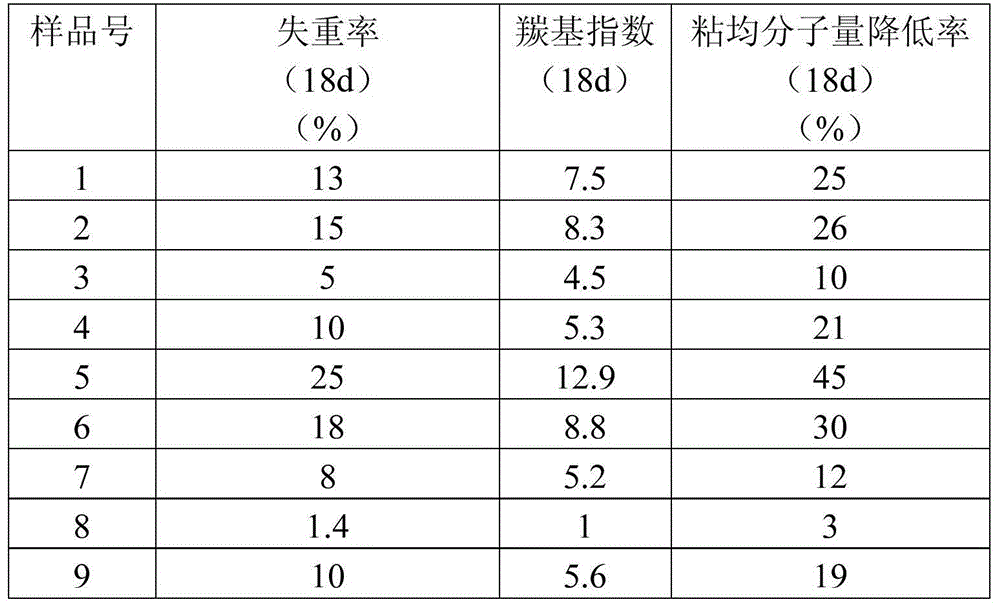

Embodiment 1

[0023] Embodiment 1, preparation of photodegradable nanometer polymer coated fertilizer

[0024] Weigh 45g of low-density polyethylene (purchased from Beijing Yanshan Petrochemical Co., Ltd., the model is 1F7B, the viscosity average molecular weight is 40700), 8.5g of filler material talcum powder and 0.6g of nano photocatalyst with a particle size of 50nm are coated with a layer of hydrophobic layer of nano-titanium dioxide (that is, hydrophobic nano-titanium dioxide, purchased from Beijing Deke Daojin Technology Co., Ltd.), mixed in 1L of tetrachlorethylene at 100-110°C to obtain a coating solution; 1kg of urea particles were placed in the jet stream In the tower, the temperature of the dry hot air is controlled at 100-110°C. Under the support of the hot air, the coating liquid is sprayed onto the surface of the suspended and fluidized urea particles through the nozzle, and the coating with a coating rate of 5% is obtained after the solvent evaporates. Fertilizer, recorded a...

Embodiment 2

[0025] Embodiment 2: Preparation of Photodegradable Nanopolymer Coated Fertilizer

[0026] Weigh 45g of low-density polyethylene (purchased from Beijing Yanshan Petrochemical Co., Ltd., the model is 1F7B, the viscosity average molecular weight is 40700), 4g of starch, 4.5g of calcium carbonate and 0.6g of nano photocatalyst with a particle size of 20nm coated with a layer of Hydrophobic layer of nano-titanium dioxide (that is, hydrophobic nano-titanium dioxide, purchased from Beijing Deke Daojin Technology Co., Ltd.), mixed in 1L tetrachlorethylene at 100-110 ° C to obtain a coating solution; 1kg urea particles were placed in the spray In the flow tower, the temperature of the dry hot air is controlled at 100-110°C. Under the support of the hot air, the coating liquid is sprayed onto the surface of the suspended and fluidized urea particles through the nozzle. After the solvent is volatilized, the coating with a coating rate of 5% Membrane fertilizer, denoted as sample 2.

Embodiment 3

[0027] Embodiment 3: Preparation of Photodegradable Nanopolymer Coated Fertilizer

[0028] Weigh 45g of polystyrene (purchased from Sinopec Yangzi BASF, the model is EPS403W, the viscosity average molecular weight is 53870), 8.5g of talc powder and 1.1g of nano-titanium dioxide with a particle size of 30nm and a hydrophilic layer on the surface (that is, hydrophilic Water-based nano-titanium dioxide (purchased from Degussa, model P25) was mixed in 1L of tetrachlorethylene at 100-110°C to obtain the coating solution; 1kg of urea particles were placed in the spray tower, and the temperature of the drying hot air was controlled At 100-110°C, the coating liquid is sprayed onto the surface of the suspended and fluidized urea particles through the nozzle under the support of hot air, and the coated fertilizer with a coating rate of 5% is obtained after the solvent is volatilized, which is recorded as sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com