Processing method used for multiple recycling of fur dyeing effluent

A treatment method, a technology for dyeing waste liquid, applied in water/sewage multi-stage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the unbearable operating cost of excess sludge, COD and chroma removal The rate is not high, the effluent can not meet the discharge standard and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Dyeing dark brown dyeing wastewater for recycling

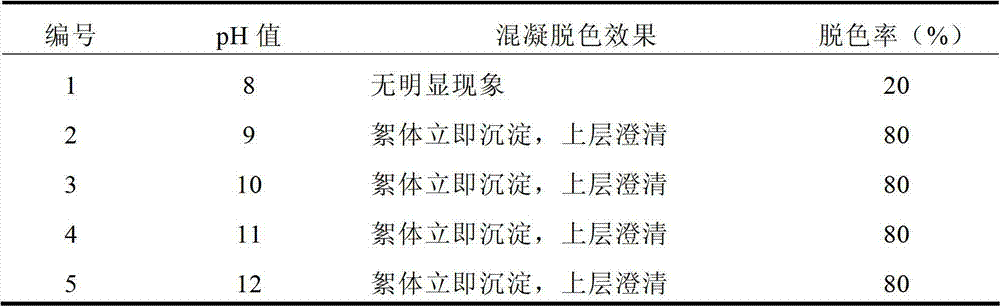

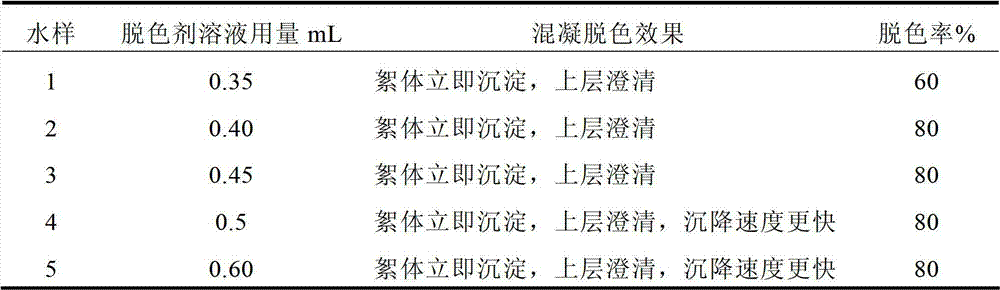

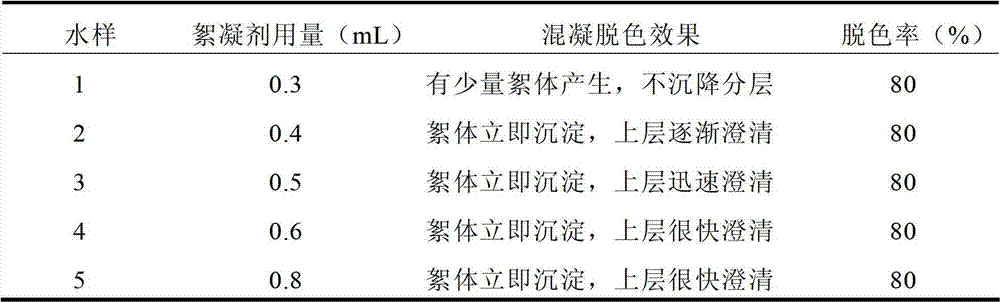

[0026] (1) After the new dye solution is dyed dark brown, take 2000 liters of wastewater, pH=3.5-4.0, chroma 2000 times, chromium content 40mg / L. Add 1.6 kg of lime (0.08% of the wastewater volume), adjust the pH=9.0-10.0, add 2.6 liters of dicyandiamide-formaldehyde polymer decolorizer solution with a concentration of 10wt% (0.13% of the wastewater volume), and add a concentration of 0.1 10 liters of wt% flocculant PAM solution (0.5% of the waste water), stir evenly, let it stand for 2 hours, pump it into the plate and frame filter press with a non-blocking sewage pipeline pump, and control the pressure of the plate and frame filter press to 18KG, The filter cloth density is 15 microns. The filtered sludge is separated, and the filtrate is used for dyeing and recycled. The chroma of the filtrate is about 200, the decolorization rate is 90%; the chromium content is 1.45mg / L, and the chromium removal rate is 96%. ...

Embodiment 2

[0052] 1. Dyeing light brown dyeing wastewater for recycling

[0053] (1) After the new dye solution is dyed light brown, take 1500 liters of wastewater, the chroma is 750, the chromium content is 39.19mg / L, and the pH=3.5-4.2. Add 1.2 kg of lime (0.08% of the wastewater volume), adjust the pH=9.0-10.0, add 3 liters of dicyandiamide-formaldehyde polymer decolorizer solution with a concentration of 10wt% (0.2% of the wastewater volume), and add a concentration of 0.1 8 liters of wt% flocculant PAM solution (0.53% of the waste water), stir evenly, let it stand for 2 hours, pump it into the plate and frame filter press with a non-blocking sewage pipeline pump, and control the pressure of the plate and frame filter press to 18KG, The filter cloth density is 15 microns. The filtered sludge is separated, and the filtrate is used for dyeing and recycled. The color of the filtrate is about 70 times, and the decolorization rate is over 90%.

[0054] It is dyed light brown with the f...

Embodiment 3

[0078] 1. Recycling of mixed dyeing wastewater dyed light brown and dark brown

[0079] (1) After the new dyeing solution is dyed light brown and dark brown, mix the two kinds of wastewater according to the volume ratio of 1:1, take 2000 liters of wastewater, the chroma is 1800 times, pH=3.5-4.2, and the chromium content is 60.07mg / L . Add 1.625 kg of lime (0.08% of the wastewater volume), adjust the pH=9.0-10.0, add 6 liters of dicyandiamide-formaldehyde polymer decolorizing agent solution with a concentration of 10wt% (0.3% of the wastewater volume), and the concentration is 0.1wt % flocculant PAM solution 6.5 liters (0.33% of the waste water), stir evenly, let it stand for 2 hours, pump it into the plate and frame filter press with a non-clogged sewage pipeline pump, control the pressure of the plate and frame filter press to 18KG, filter The cloth density is 15 microns. The filtered sludge is separated, and the filtrate is used for dyeing and recycled. The chroma of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionicity | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com