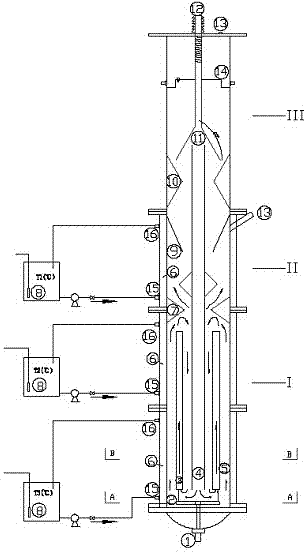

Bypass-type constant-temperature internal-circulation anaerobic sludge bed reactor

An anaerobic sludge bed and internal circulation technology, applied in anaerobic digestion treatment, waste fuel, etc., can solve the problems of poor adaptability to sudden changes in water quality and load, large differences in sludge bed fluid state, and affecting treatment capacity, etc., to achieve Prolonged contact process, improved treatment effect, reduced effect of limiting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

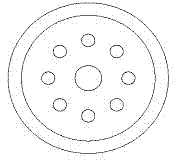

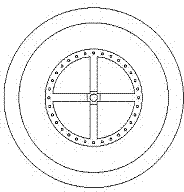

[0016] High-concentration organic wastewater containing oil enters from the bottom water inlet pipe 1, and passes through the large-resistance annular water distribution coil 2. The upper part of the coil is equipped with water distribution holes at equal intervals. The anaerobic suspended sludge layer becomes an independent small anaerobic sludge bed, and the water flows upward in the diversion pipe 3. When the water flow rises to the outlet through the diversion pipe, it is deflected by the baffle plate 7 of the first-stage three-phase separator. Part of the muddy water diverges downward after deflection, returns to the lower water inlet of the diversion pipe 3, mixes with the incoming water and enters the diversion pipe 3, and forms a circulating flow (first-stage circulation) in the large sludge area 5; the other part diverts upward and enters the first stage In the sedimentation area of the three-phase separator, the mud and water are initially separated, and the biogas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com