Take-up and pay-off device applied to mobile device

A technology for retracting and unwinding devices and mobile equipment, which is applied in the field of cable winding devices, which can solve problems such as pedestrians falling, short circuits, metal objects falling into the ditch, etc., and achieve the effects of avoiding sprains, simplifying the system structure, and not consuming electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

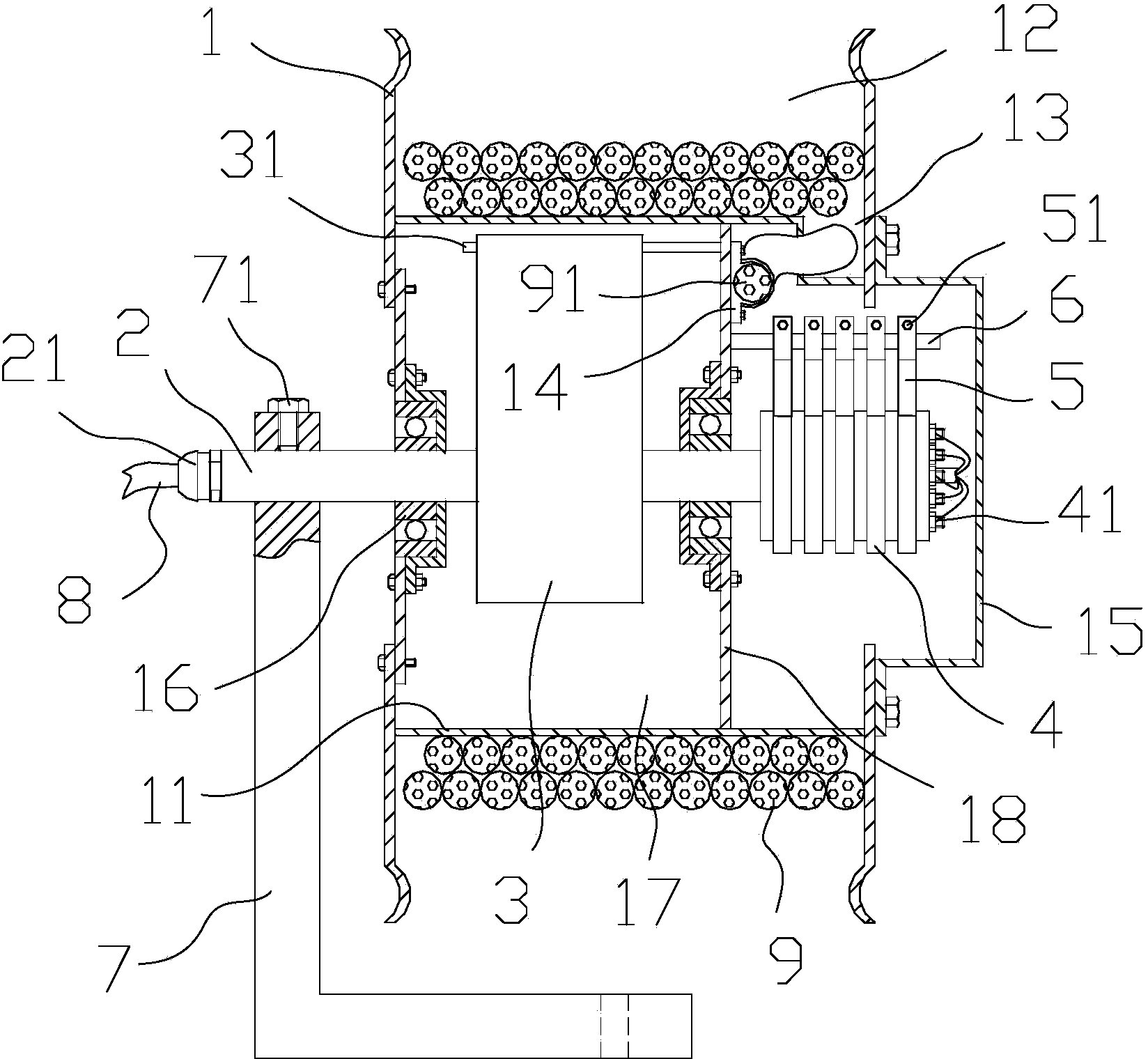

[0013] Such as figure 1 As shown, the bracket 1 is fixed on the mobile device.

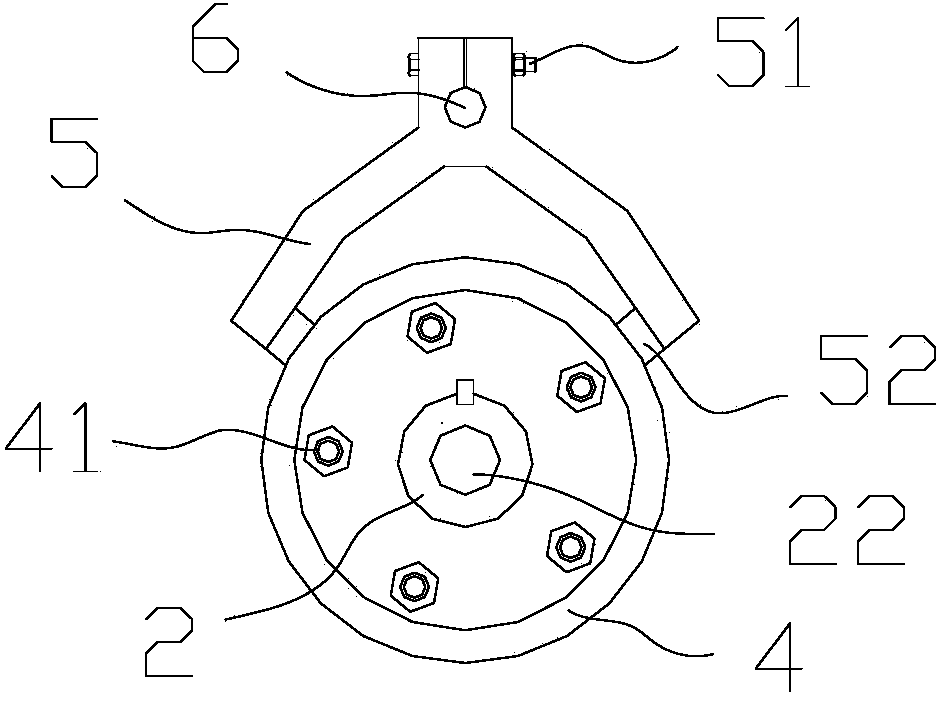

[0014] The wire reel 1 is provided with an annular wire groove 12, the cable 9 is wound in the wire groove 12, the hollow mandrel 2 is fixed through the bearing 16 in the middle of the wire reel 1, and there is an annular cavity 17 inside the ring inner wall at the bottom of the wire groove 12 , the cavity 17 is equipped with a scroll spring 3, the inner end of the scroll spring 3 adopts a straight hook type, and is fixed on the mandrel 2 through a card slot embedded in the mandrel 2, and the outer end of the scroll spring 3 adopts a hinged type, Slip on the pull rod 31 that is fixedly connected with the side wall 18 of the wire tray.

[0015] Both ends of the mandrel 2 extend to the outside of the coil 1 . Wherein, the bracket 7 is provided with a shaft hole for the mandrel 2 to pass through, and one end of the mandrel 2 is fixed on the bracket 7 through the shaft hole, and the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com