Novel bus lifting ring handle

A bus and handle technology, applied to the special position of the vehicle, transportation and packaging, vehicle components, etc., can solve the problems of poor shock absorption and cushioning, and achieve the effect of increasing the ride experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

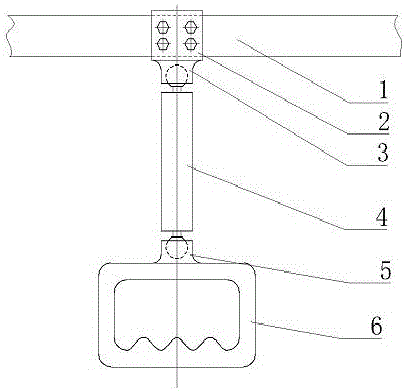

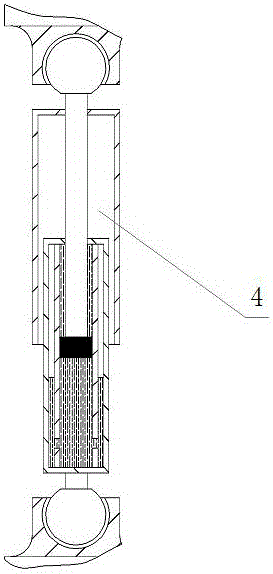

[0025] Bus bracket 1 is a common bus bracket. The fixed support 2 is carbon steel. The spherical joint 3 is a hemispherical joint, which can realize a deflection of 120 degrees. Part 4 is preferably a hydraulic shock absorber. The spherical joint 5 is a hemispherical joint, which can realize a deflection of 120 degrees. Handle 6 is carbon steel.

[0026] Example of use

[0027] When the vehicle bumps, brakes in an emergency, or turns sharply, the human body will generate huge pulling force and torsion force due to the effect of inertia, and the shock absorber 3 reduces a part of the pulling force through hydraulic damping to play a buffering role. The ball joint can rotate 120 degrees in any direction, which prevents the human body from being sprained, and is also convenient for passengers to adjust their body posture arbitrarily.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com