A silver fiber multi-layer fabric with high electromagnetic shielding

An electromagnetic shielding and silver fiber technology, applied in the field of silver fiber multi-layer fabrics, can solve the problems of affecting the electromagnetic shielding durability of fabrics, reducing the shielding performance, affecting the appearance, etc., to achieve excellent electromagnetic shielding efficiency, improve service life, reduce oxidation and other problems. Possible effects of sun exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

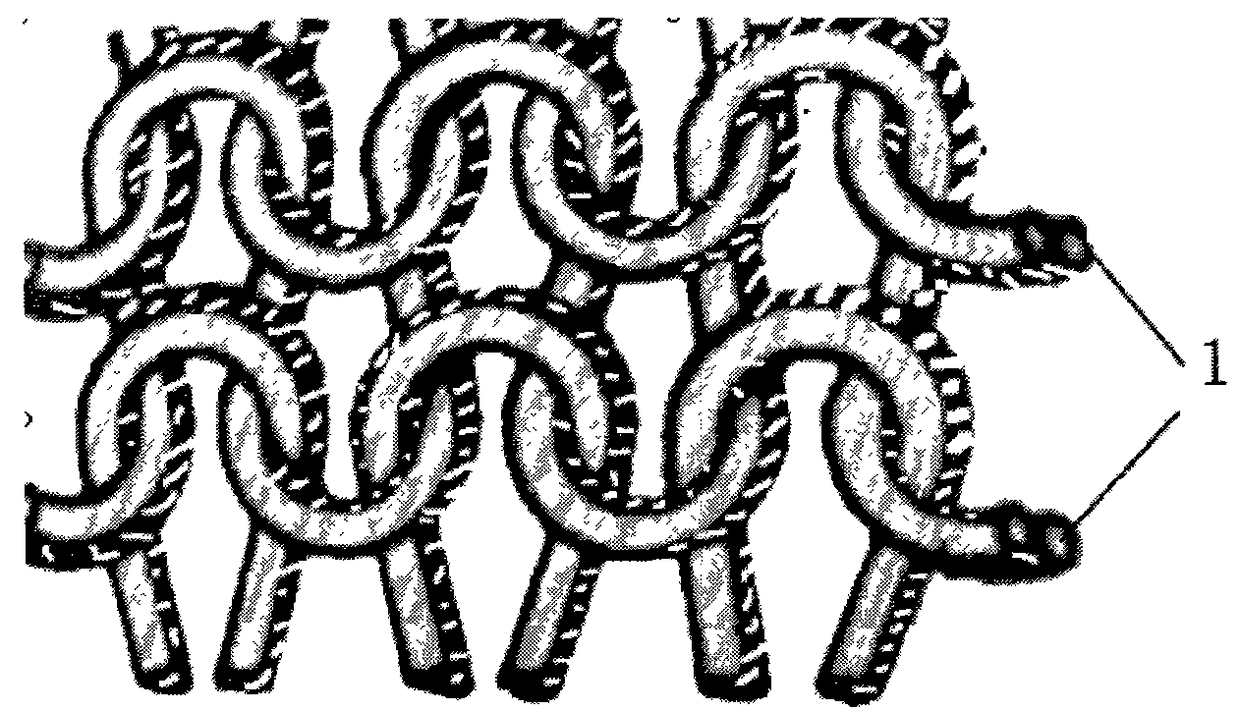

[0020] figure 1 It is a schematic diagram of the lapped yarn structure of the traditional weft flat weave, including silver fiber 1 and yarn weave.

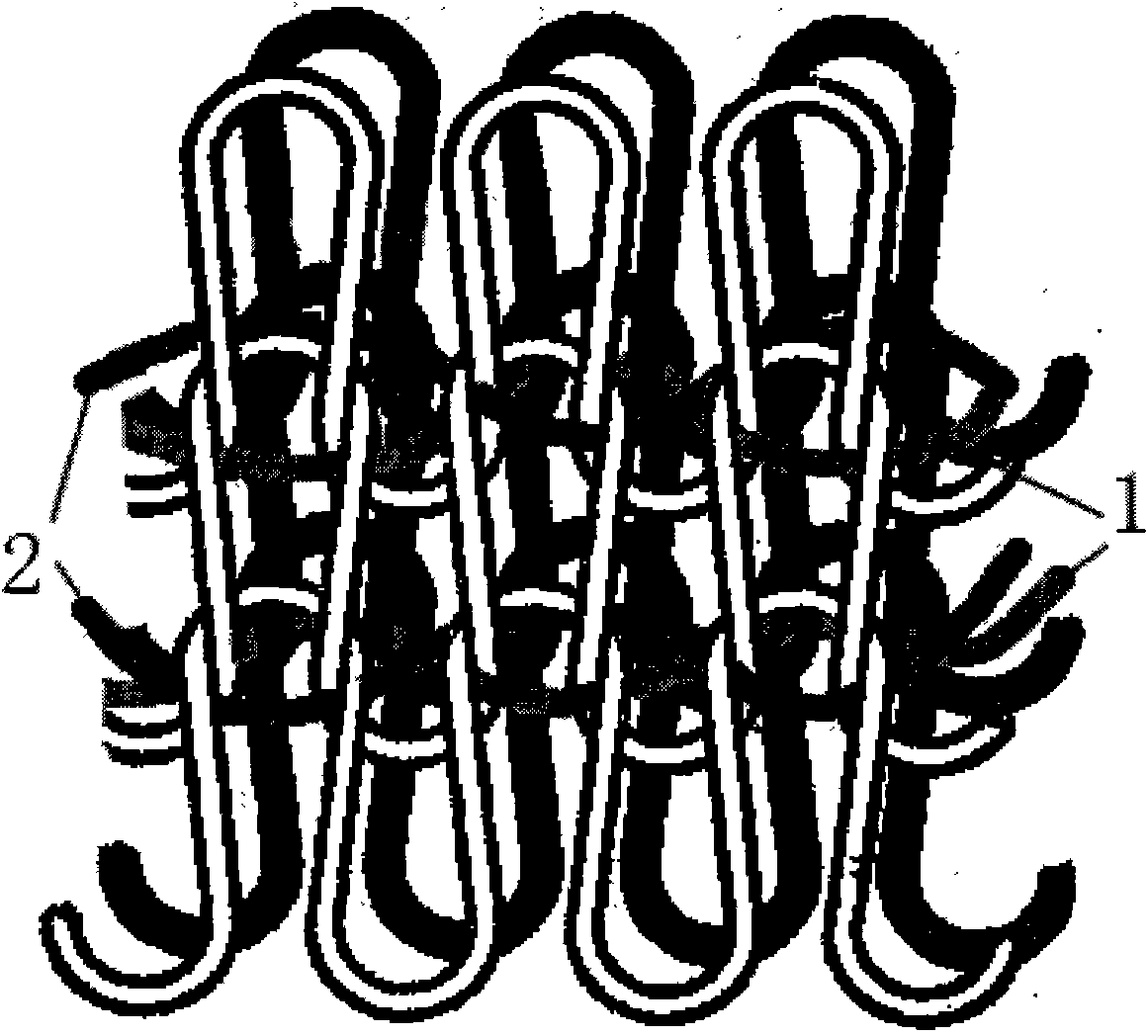

[0021] like image 3 Shown, a kind of silver fiber multi-layer fabric of high electromagnetic shielding, comprises the surface layer and the inner layer that feel is soft that 10tex cotton yarn is formed by fineness, is provided with such as between the surface layer and the inner layer image 3 The shown 70D silver fiber tissue layer with a three-dimensional groove structure for connecting the surface layer and the inner layer as electromagnetic shielding, the silver fiber tissue layer is composed of silver fiber 1 and silver fiber 2, and the silver fiber tissue layer is evenly distributed For each row of the healthy cloth fabric, the silver fibers between two adjacent rows are in close contact with each other due to shrinkage and hot-pressing to form a three-dimensional groove structure. The shrinkage rate of the fabric is con...

Embodiment 2

[0023] The same part of this embodiment and embodiment 1 will not be repeated, and its difference is: the shielding tissue layer is formed between the surface layer and the inner layer by the silver fiber 1 of 150D with a full set of circles, such as Figure 4 As shown, this structure can endow the healthy cloth fabric with better electromagnetic shielding effect.

[0024] The silver fiber tissue layer is evenly distributed in each row of the healthy cloth fabric, and the silver fibers 1 in two adjacent rows are in close contact with each other due to shrinkage and hot pressing to form a three-dimensional groove structure in space, and the shrinkage rate of the fabric is controlled within 1%. , the hot-pressing setting temperature is 180°C, the hot-pressing speed is 50 m / min, the line pressure is 88 kg / cm, and the fabric weight is controlled at 220-260 g / m 2 between.

Embodiment 3

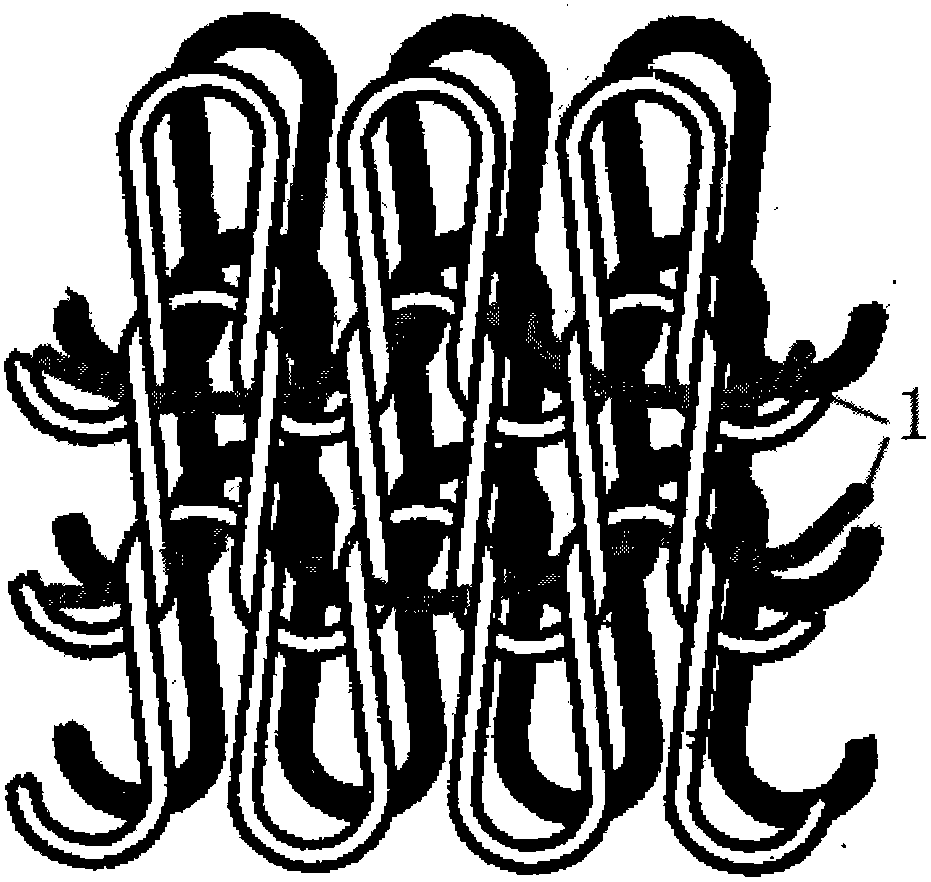

[0026] A high electromagnetic shielding silver fiber multi-layer fabric, including a soft surface layer and an inner layer formed by a cotton yarn with a fineness of 14.5tex, between the surface layer and the inner layer is arranged such as figure 2 The 40D silver fiber tissue layer with a three-dimensional groove structure used as electromagnetic shielding to connect the surface layer and the inner layer is shown. The silver fiber tissue layer is composed of silver fibers 1. This structure can endow the healthy cloth fabric with excellent electromagnetic shielding effect .

[0027] The silver fiber tissue layer is evenly distributed in each row of the healthy cloth fabric, and the 40D silver fibers in two adjacent rows are in close contact with each other due to shrinkage and hot pressing to form a three-dimensional groove structure in space, and the shrinkage rate of the fabric is controlled at 2%. Within the range, the hot-press setting temperature is 170°C, the hot-press ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com