OSB (oriented strand board) high-strength composite wood veneer and production process thereof

A production process and veneer technology, applied in the field of sheet metal, can solve the problems of messy cracks, uneven surface, limited use, etc., to achieve the effect of smooth surface, good quality, scientific and reasonable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

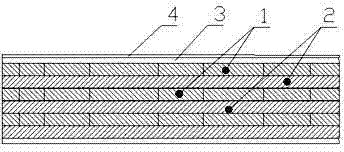

[0032] As shown in the figure, the present invention includes an OSB board. The OSB board is composed of a group of horizontal layers 1 and a group of vertical layers 2. The horizontal layer 1 and the vertical layer 2 are composed of several solid wood sheets respectively. A group of horizontal layers 1 and a group of vertical layers The vertical layer 2 of the group is formed by alternate bonding of formaldehyde-free glue. The wood grain of the solid wood veneer of the horizontal layer 1 and the grain of the solid wood veneer of the vertical layer 2 are arranged in a cross pattern. It also has a veneer 3, which is pasted on the OSB board. upper surface or / and lower surface. The veneer 3 is pasted on the upper surface of the veneer 3 . Veneer panel 3 is technical veneer or fiberboard.

[0033] Technical veneer (commercially available products, also known as veneer or artificial veneer) is a kind of performance that is produced by ordinary wood (fast-growing wood) as raw mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com