Rotary table transmission device of numerical control spiral bevel gear milling machine

A technology of spiral bevel gear and transmission device, which is applied in the field of CNC spiral bevel gear milling machine turntable transmission device, can solve the problems that affect the gear machining accuracy and tooth surface finish, the vibration marks on the gear tooth surface, and low-speed crawling, etc., and achieve improvement The smoothness of the tooth surface, the improvement of machining accuracy, and the effect of smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

[0022] It should be noted that, unless otherwise expressly specified and limited, the terms "first", "second", etc. do not represent sequential installation, nor do they represent the importance of the described components.

[0023] Examples of such embodiments are illustrated in the accompanying drawings, wherein the same or similar reference numerals refer to the same or similar parts or parts having the same or similar functions throughout.

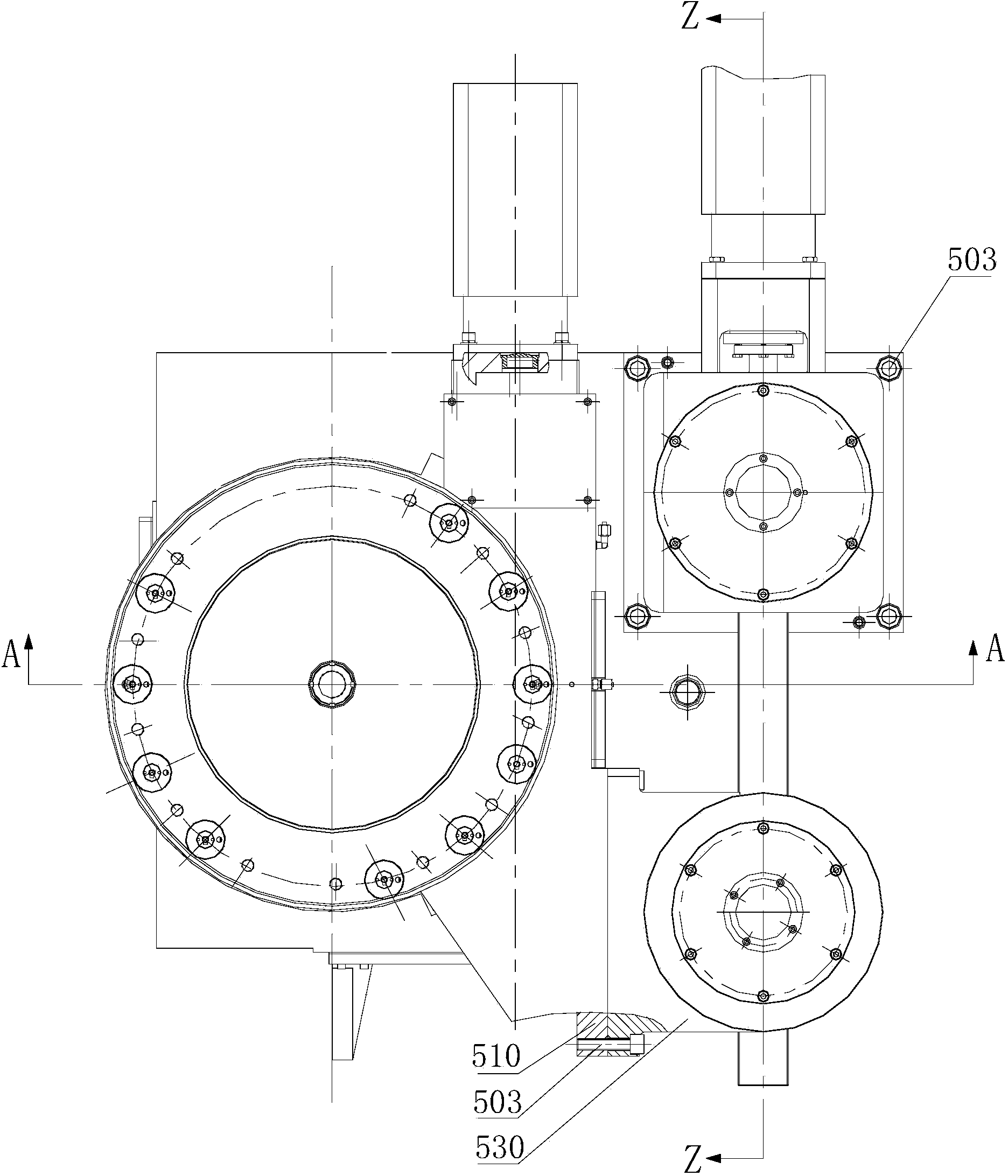

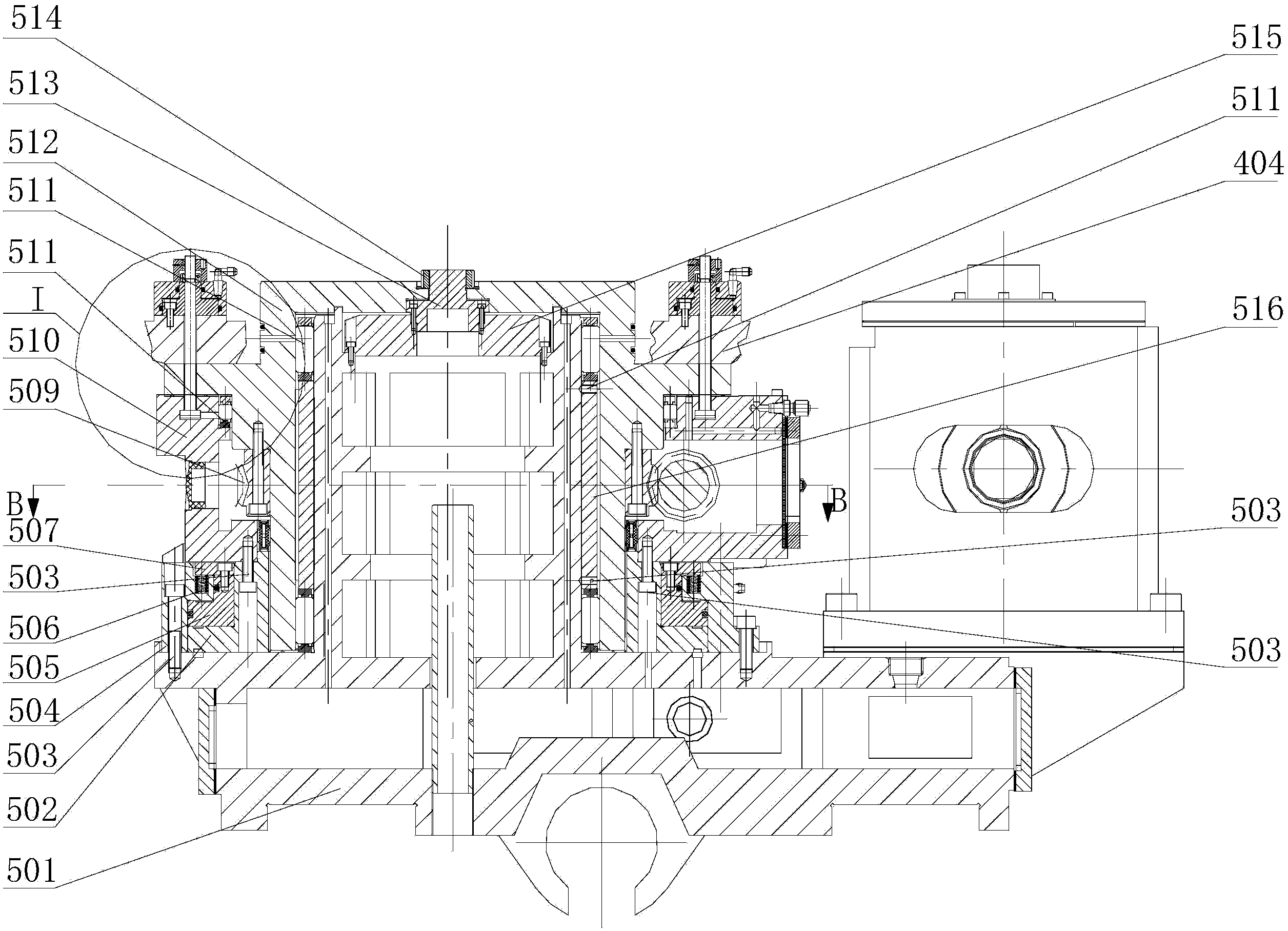

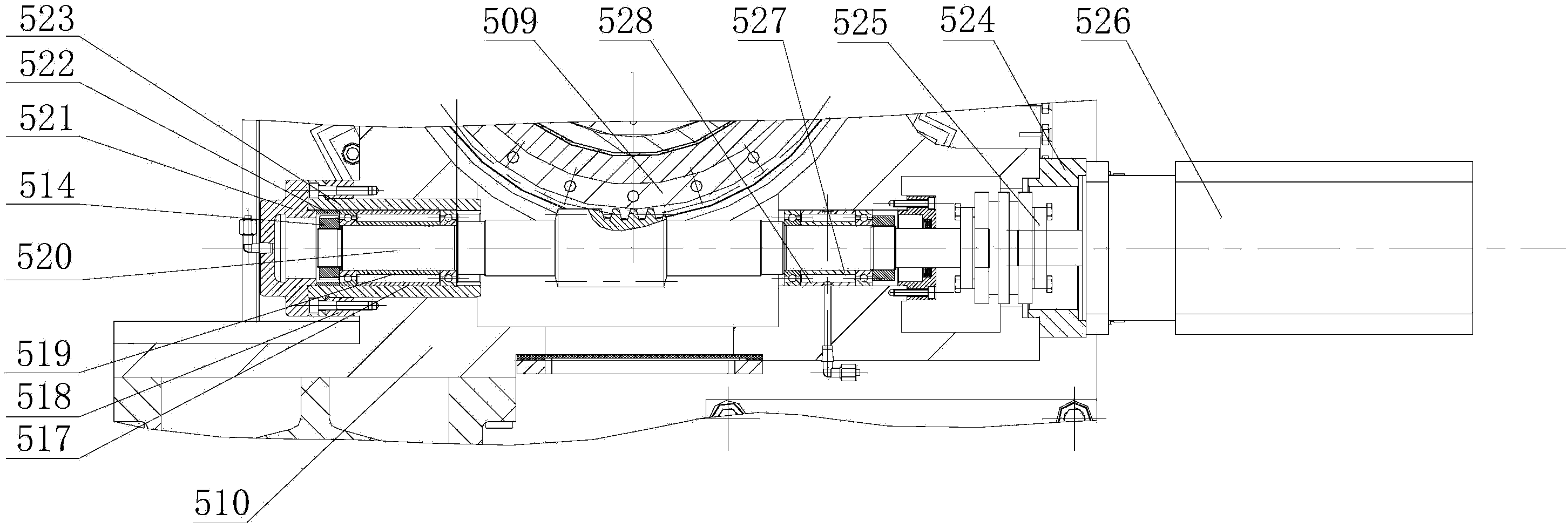

[0024] see Figure 1-Figure 5 , the turntable transmission device of the CNC spiral bevel gear milling machine, including the feed slide 501 and the turntable base 510, and also includes the worm gear bottom sleeve 512 for driving the turntable to rotate. The turntable swing lever mechanism, the second clamping c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com