Serration-type steel reinforcement cage machining jig frame and construction method thereof

A construction method and reinforcement cage technology, applied in the direction of wire rod processing, other household appliances, and wire manufacturing of ring nets, etc., can solve the problems of inability to form flow operations, uneven distribution of main reinforcement, slow construction progress, etc., and reduce construction work. The investment of personnel and equipment, the reduction of processing costs, and the effect of construction quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following non-limiting examples illustrate the invention.

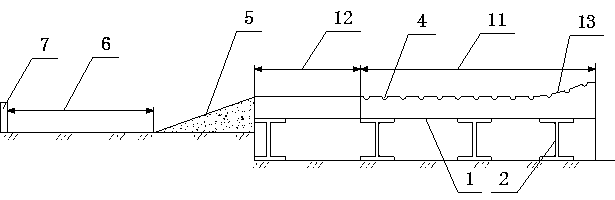

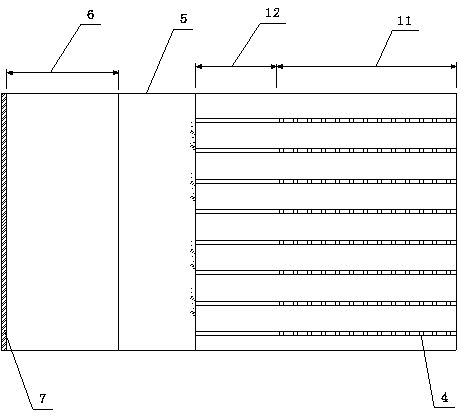

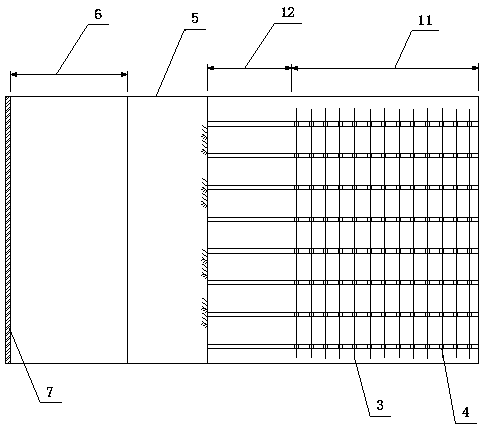

[0034] Such as Figures 1 to 3 As shown, a tire frame processed by a sawtooth steel cage includes several strip-shaped tire frames arranged side by side. The tire frame is composed of a tire frame body 1 and a bracket 2 supporting the tire frame body 1. The tire frame body 1 is A steel plate, the bracket 2 is made of section steel, the tire frame is divided into the main reinforcement welding and forming area 11 and the spiral reinforcement binding area 12 along its length direction, and the main reinforcement welding and forming area 11 is far away from the spiral reinforcement binding area 12, and the tail of one end is a circle Arc segment 13, its upper surface is raised in an arc, and the upper surface of arc segment 13 is a 45° arc; tire frames are arranged horizontally, and each tire frame is parallel to each other and the upper surface is even; the main rib welding and forming area 11 The surface is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com