Intelligent control double-meshing automobile gear precision detection system

A technology for automobile gear and precision detection, which is applied in the direction of machine gear/transmission mechanism testing, vehicle testing, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

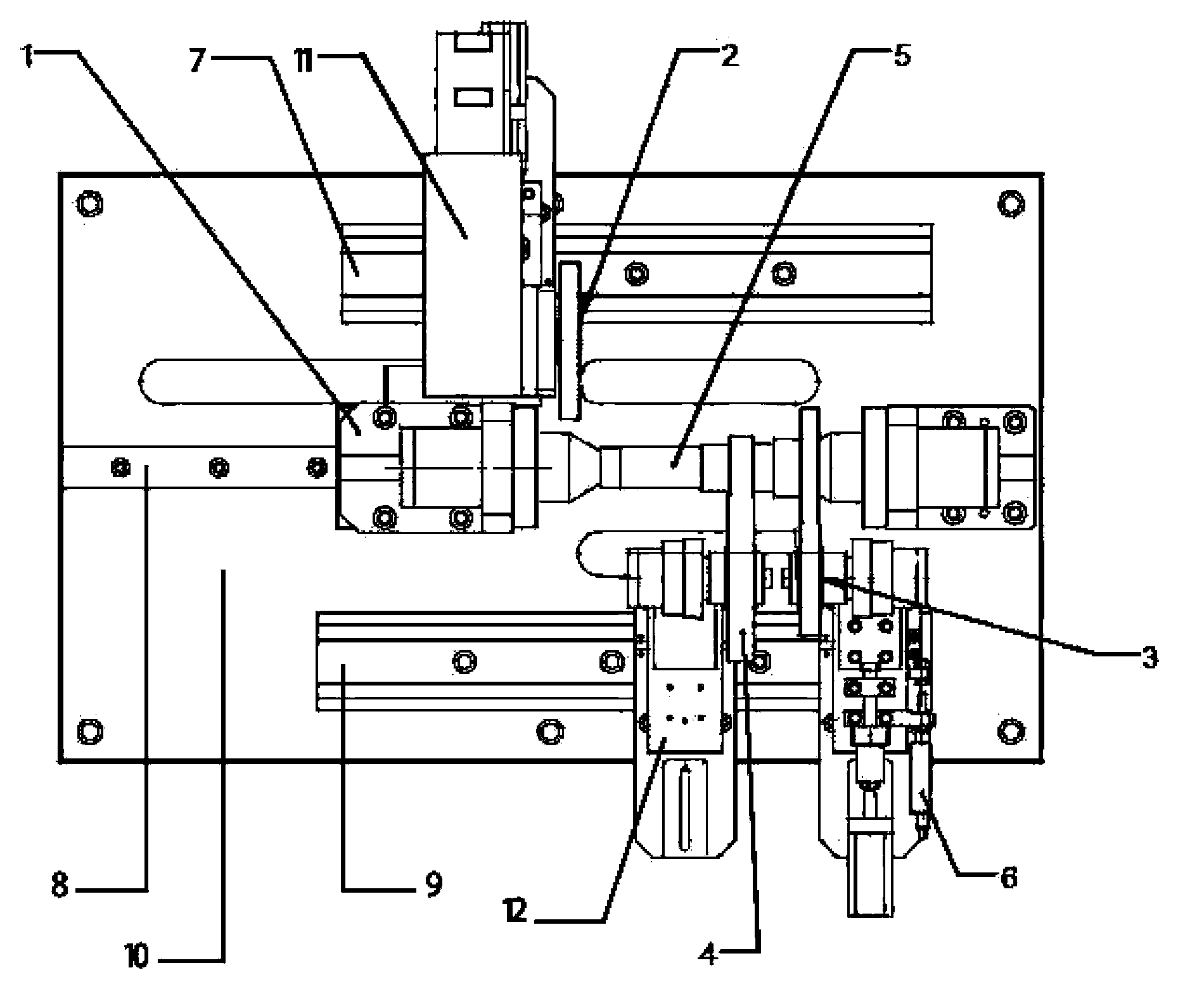

[0029] Such as figure 1 , a double tooth meshing instrument, comprising a base 10, a guide rail, a fastening device, a driving device, and a testing device, wherein the guide rail is fixed on the base 10 and is in three parallel upper, middle and lower sections; the driving device and The upper guide rail 7 is connected; the test device is fixed on the lower guide rail 9; the fastening device is connected to the middle guide rail 8, and it is characterized in that the fastening device is divided into two ends, and one end is fixed on the base 10, The other end is provided with a propulsion cylinder 1, and is fixed on the guide rail corresponding to its position direction; the test device is provided with a displacement sensor 6 and a high-precision standard test wheel, and the upper section guide rail 7, the middle section guide rail 8, the lower section The guide rails 9 are all dovetail groove guide rails, which can freely slide back and forth in the axial direction, so as t...

specific Embodiment 2

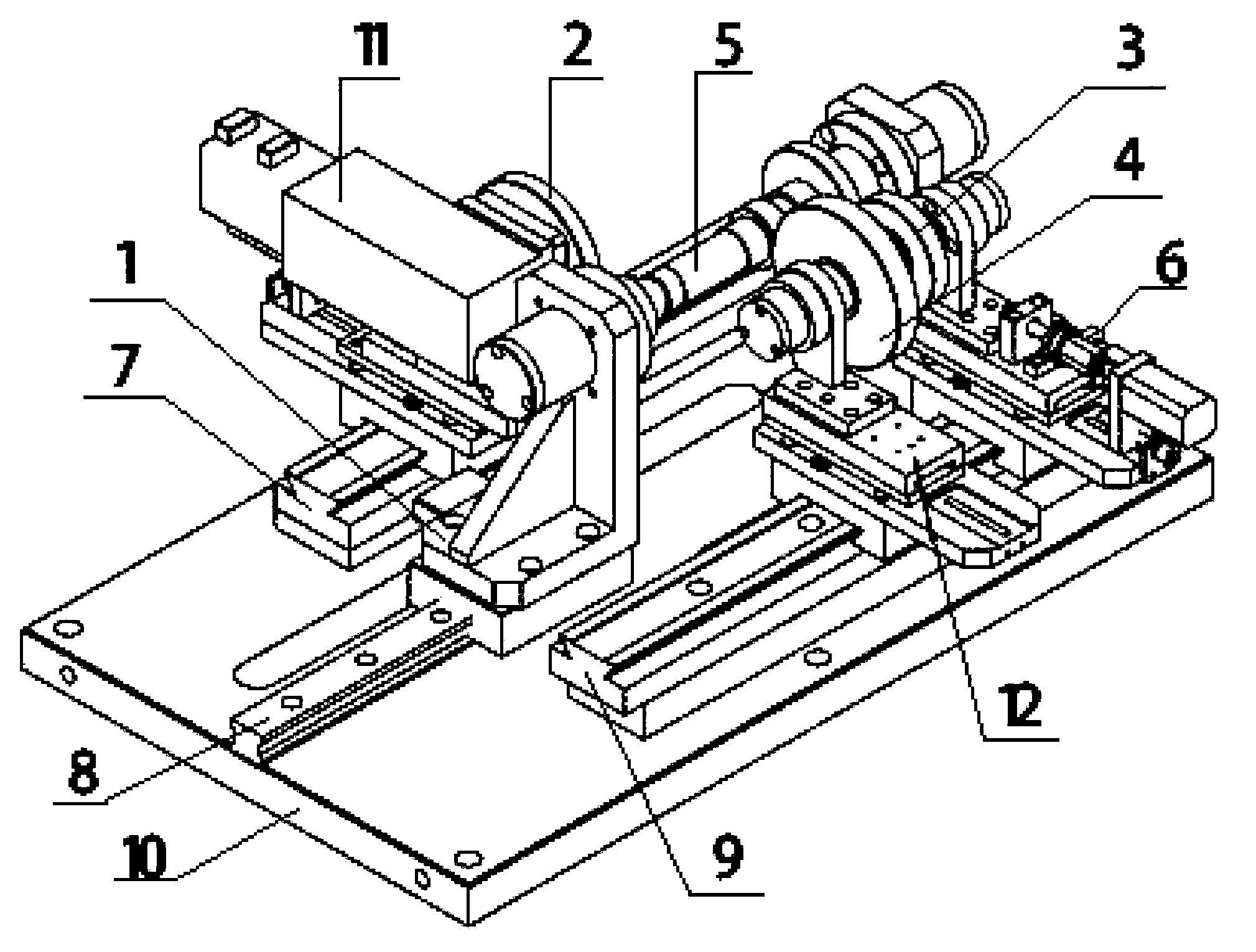

[0030] Such as figure 2 As shown, when the workpiece 5 to be tested is placed at the corresponding position of the fastening device, the continuous pressure of 0.5-0.6 MPa is provided by the push cylinder 5 to fasten the workpiece 5 to be measured at the corresponding position to be tested. The driving device The drive gear 2 and the servo motor 11 are provided and connected to each other, the drive gear 2 is driven by the servo motor 11 to rotate radially, and the upper guide rail 7 is used to axially move to the position of the corresponding workpiece 5 to be measured, and then the sliding table device is used 12 Make its drive tooth 2 contact the gear of the workpiece to be measured and mesh with each other, and drive the workpiece 5 to be measured to rotate.

specific Embodiment 3

[0031] Such as figure 2 As shown, after the workpiece 5 to be tested is placed in place, use the accurate detection position detected by the displacement sensor 6 to move the overall testing device axially from the lower guide rail 9 to the corresponding detected position of the workpiece 5 to be tested, and then use the sliding table device 12 Make the small-diameter standard test wheel 3 and the large-diameter standard test wheel 4 mesh with the gear of the tested workpiece, and test to obtain the total measurement center distance variable of the measured workpiece 5 gears, a tooth degree variable, runout, burr, M value and other gear data to achieve the purpose of detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com