Intelligent high-efficiency direct-mix heat exchanger unit

A heat exchange unit and high-efficiency technology, applied in the direction of household heating, heating mode, household heating, etc., can solve the problems of poor mixing effect, slow valve adjustment, affecting the thermal efficiency of the system, etc., to achieve improved water mixing effect, precision Improve and ensure the effect of heating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

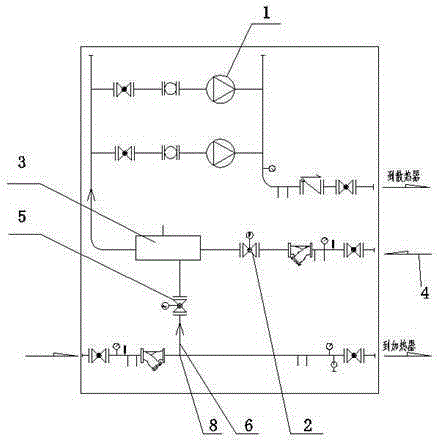

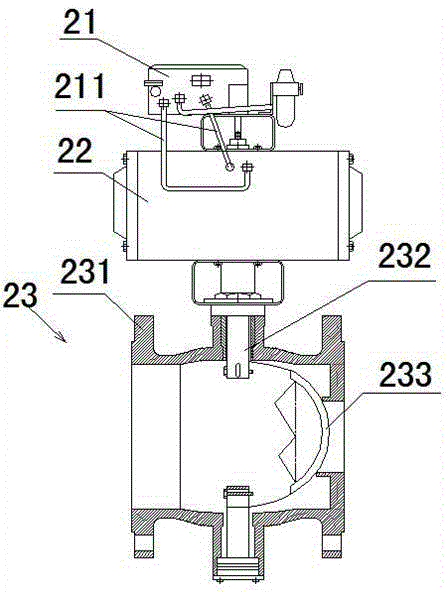

[0012] see figure 1 , the water mixing pipeline 6 is connected between the return water tee 8 bypass and the water supply tee bypass, the water supply tee is a three-way mixing tank 3, and the pipeline at the water supply inlet of the three-way mixing tank Connect to the first pneumatic regulating valve 2; connect to the second pneumatic regulating valve 5 on the water mixing line; see figure 2 , the pneumatic regulating valve includes a valve 23, a pneumatic actuator 22 and a valve positioner 21. The valve is a split welded unequal diameter valve, and its valve body 231 is composed of two split parts and then welded. Yes, the two splits mean that they are cut into two symmetrical parts along the axial direction of the valve body (the axial direction of the inlet and outlet of the valve), and each split body is formed by die-casting; the outlet diameter of the valve is the diameter of the inlet 1.1-1.5 times, that is, the inlet of the valve is smaller than the outlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com