External double lip skeleton oil seal

A skeleton oil seal and skeleton technology, applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve problems such as inconvenient disassembly, and achieve cost-saving, low-cost, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

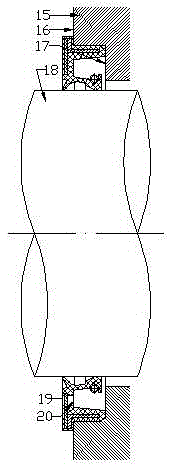

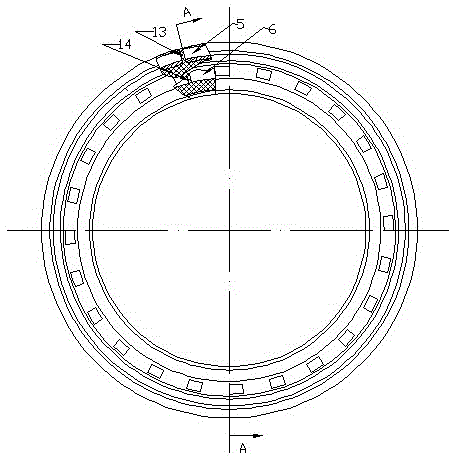

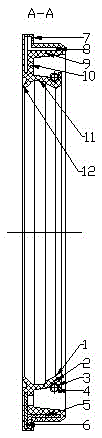

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

[0028] This embodiment discloses an externally mounted double-lip frame oil seal, the design concept of which is: design the ring pad-shaped frame 5 and the L-shaped frame 6, and use the ring pad-shaped frame 5 and the L-shaped frame 6 to be fixed or made into one body structure together constitute the radial and axial support mechanism of the external double-lip skeleton oil seal to solve the problem of the support strength of the shoulder 9 and the back 10. The part placed in the limit step 7 with the ring pad-shaped skeleton 5 and the L-shaped skeleton 6 provides sufficient mechanical strength for online disassembly. The split and partially split structures of the ring pad-shaped skeleton 5 and the L-shaped skeleton 6 provide convenience for online disassembly, disassembly and removal.

[0029] See the specific structure Figure 1-Figure 3 .

[0030] See attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com