A Self-adjusting Device for Bearing Pretightening Force Based on Piezoelectric Ceramic Actuator

A technology of bearing preload and piezoelectric ceramics, applied in transmission parts, manufacturing tools, mechanical equipment, etc., can solve problems such as difficulty in processing intermediate rings, reducing bearing life and rigidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation method of the present invention will be further described below in conjunction with the accompanying drawings.

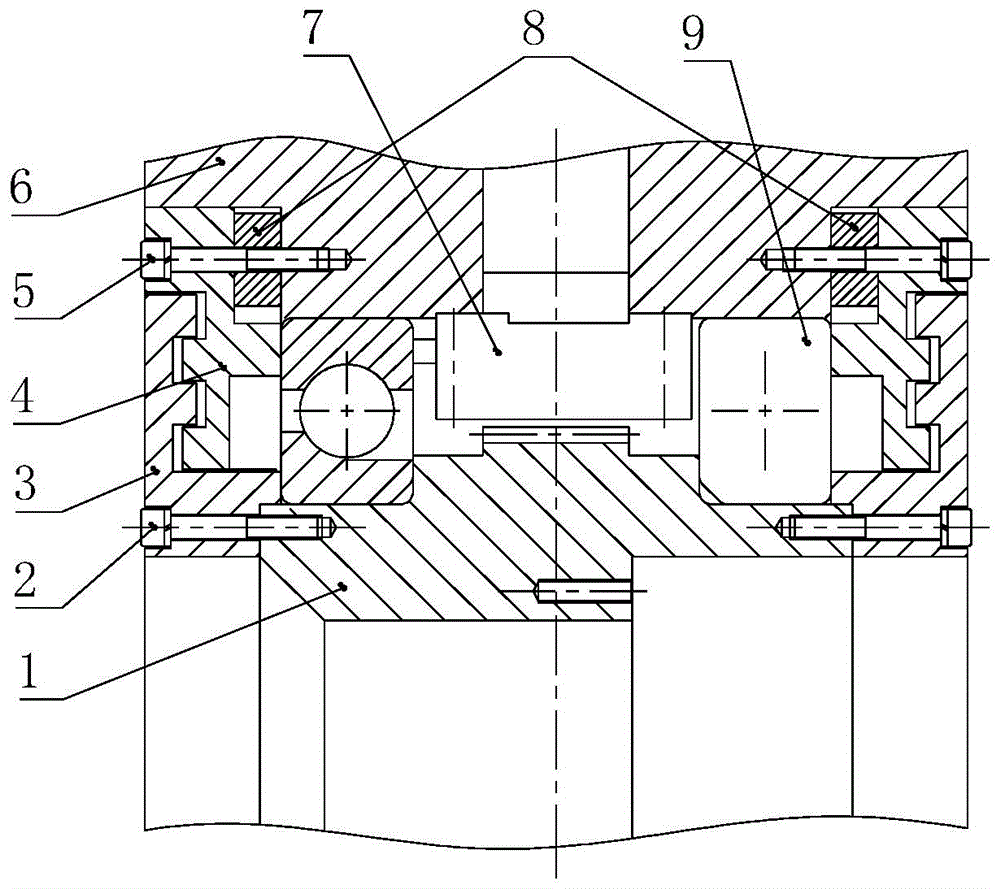

[0027] Such as figure 1 As shown, the main shaft 1 adopts a hollow design, and the parts and clamps are installed in the cavity of the main shaft. An angular contact ball bearing 9 with a relatively large diameter is used as a support. The sealing of the main shaft 1 adopts a labyrinth seal. The outer ring 3 of the labyrinth seal is fixed on the main shaft 1 by the hexagon socket head cap screw 2, and the outer ring of the labyrinth seal rotates together with the main shaft. The outer ring 3 of the labyrinth seal and the shoulder of the main shaft 1 fix the inner ring of the bearing. The inner ring 4 of the labyrinth seal is fixed on the installation base 6 through the hexagon socket head cap screw 5, which together with the piezoelectric ceramic actuator 7 fixes the outer ring of the bearing, and during the installation process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com