Automobile magnetic oil pan

A kind of oil pan and magnetic technology, which is applied in the direction of casing, engine components, machine/engine, etc., can solve the problems of secondary wear of the engine, large area of the oil pan, incomplete cleaning of iron filings, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

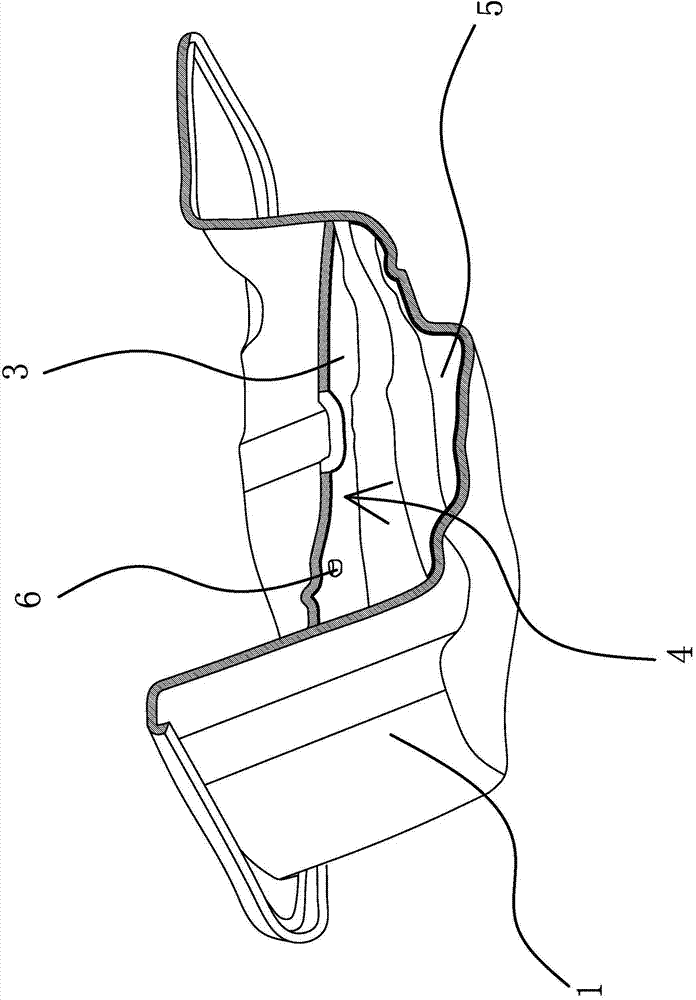

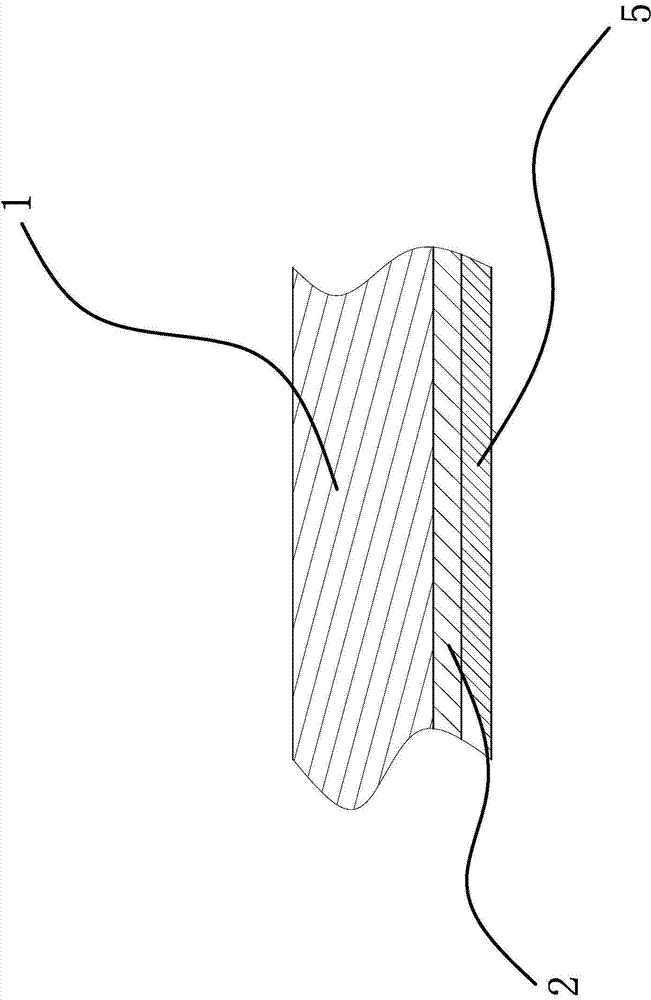

[0029] Such as figure 1 , figure 2 and image 3 As shown, a magnetic oil pan for automobiles, the inner wall of the oil pan 1 is provided with a magnetic layer 2, the upper part of the oil pan 1 is provided with an oil baffle plate 3, and an oil baffle plate 3 is provided between the oil baffle plate 3 and the bottom of the oil pan 1. The magnetic layer 2 is distributed on the bottom and side walls of the oil pan 1 for shielding the magnetic field generated by the magnetic layer 2; the magnetic layer 2 covers the entire bottom of the oil pan 1, and the side walls of the oil pan 1 are partially covered with The magnetic layer 2, the vertical height of the side wall of the oil pan 1 covered with the magnetic layer 2 is 5cm to 15cm; the magnetic layer 2 covers the inner wall of the oil pan 1 in a large area, which can strengthen the magnetization effect of the magnetic layer 2 on the oil and absorb iron The magnetic layer 2 is permanent magnet powder electroplated or sprayed o...

Embodiment 2

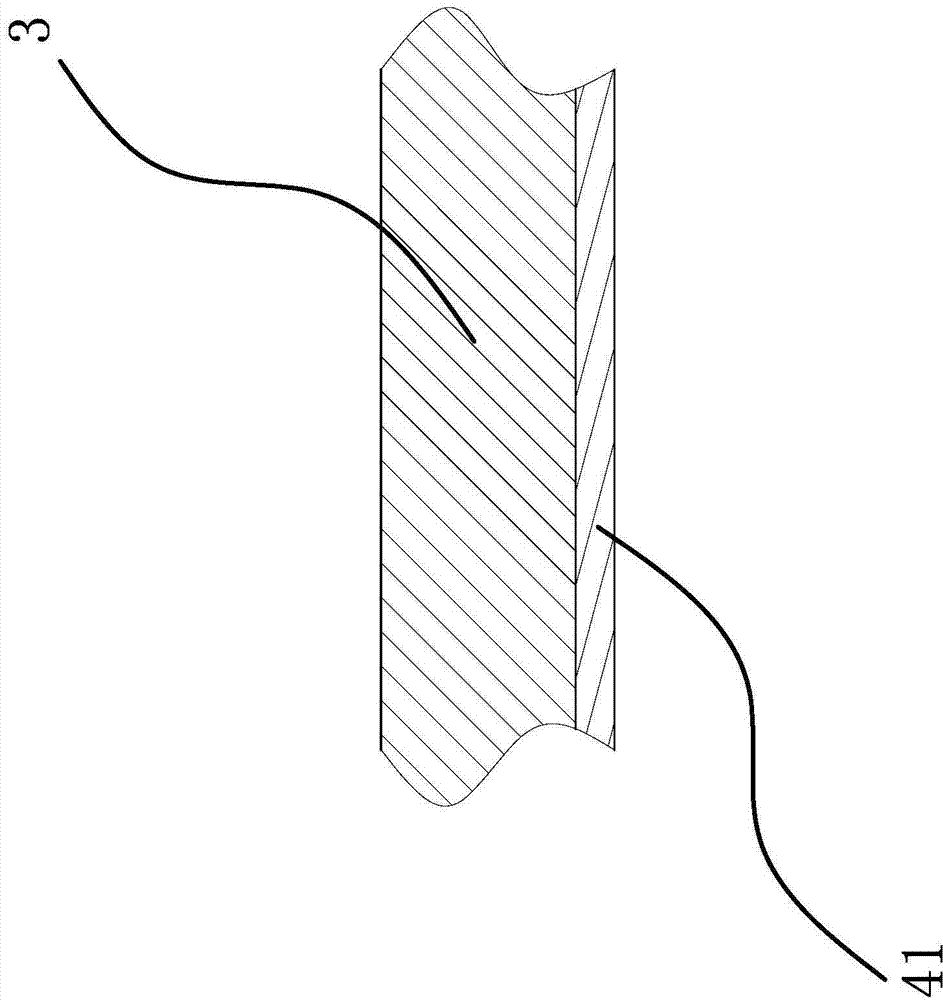

[0036] Such as Figure 4 As shown, the content of this embodiment is roughly the same as that of Embodiment 1, the difference is that the antimagnetic structure 4 includes a baffle 42 fixed on the inner wall of the oil pan 1, and the baffle 42 is located at the oil return hole 6 of the oil baffle 3 Below, the lower surfaces of the oil baffle 3 and the baffle 42 are pasted with a foil shielding layer 41, and the foil is low-carbon iron; this solution can eliminate the possibility of magnetic flux leakage through the oil return hole 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Vertical height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com