Wheel hoeing machine

A loader and wheeled technology, used in transportation and packaging, earth movers/shovels, mechanically driven excavators/dredgers, etc. Safety hazards and other issues, to achieve the effect of reducing casualties, work safety and reliability, and eliminating safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

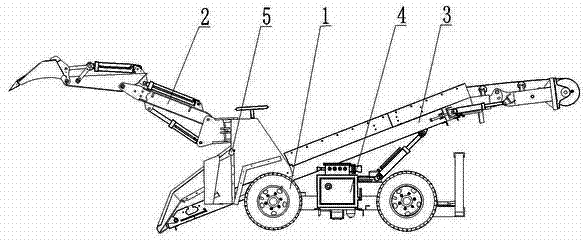

[0030] Such as figure 1 As shown, the present invention integrates a vehicle chassis 1 , an excavation loading mechanism 2 , a conveying and unloading mechanism 3 , an electrical control system 4 , a hydraulic system and its operating mechanism 5 . The motor is driven by an external power supply or a built-in diesel engine as a power source, and electric, hydraulic and mechanical transmissions are used to combine the working mechanism and the running mechanism in the form of a vehicle to form a self-moving pick-and-place machine to realize the walking, steering and braking of the whole machine. . The digging and loading mechanism has functions such as turning, digging, and loading and loading; the conveying and unloading mechanism has functions such as pushing, collecting, receiving, conveying, unloading, lifting, and folding (or telescopic).

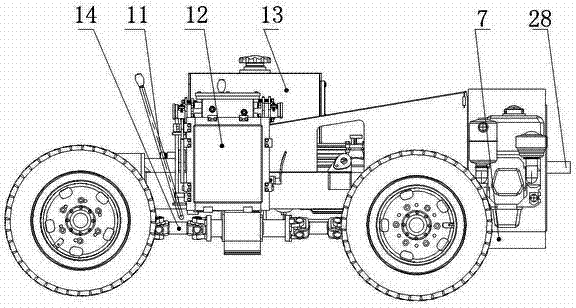

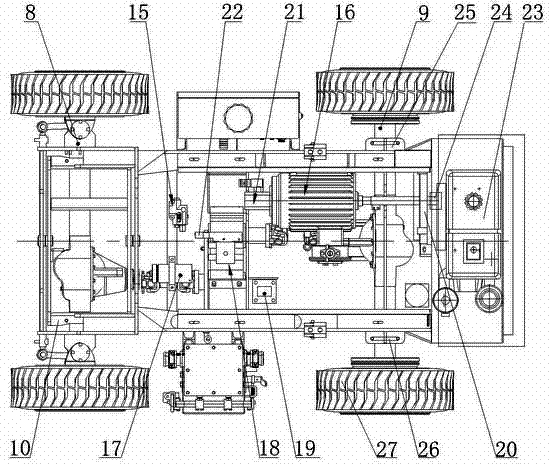

[0031] Such as figure 2 , image 3 As shown, the vehicle chassis is mainly composed of chassis frame 7, front axle 8, rear axle 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com