Device for turning over cop and cop bobbin

A bobbin and bobbin technology, applied in transportation and packaging, textile and papermaking, thin material processing, etc., can solve problems such as elastic liner wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

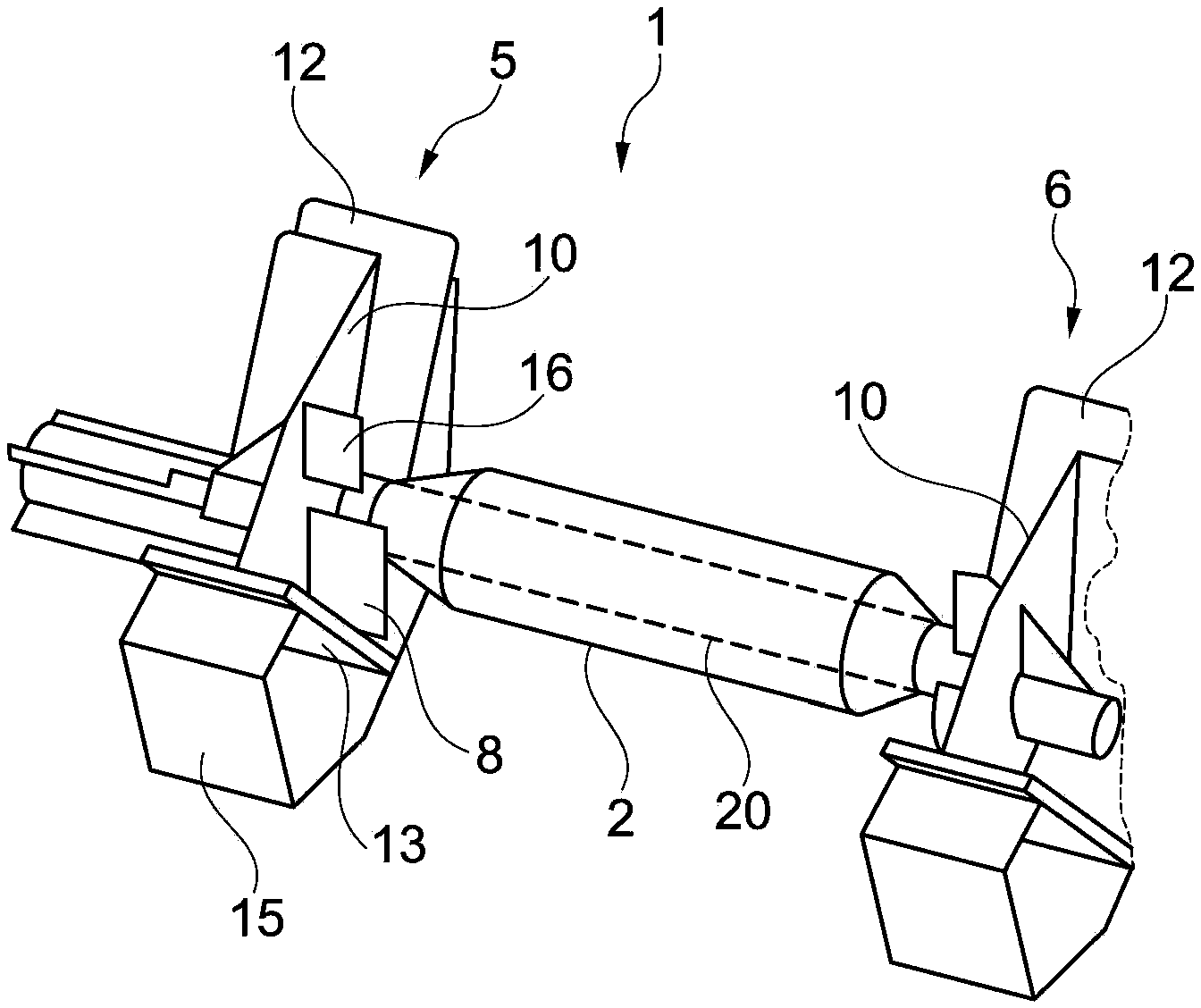

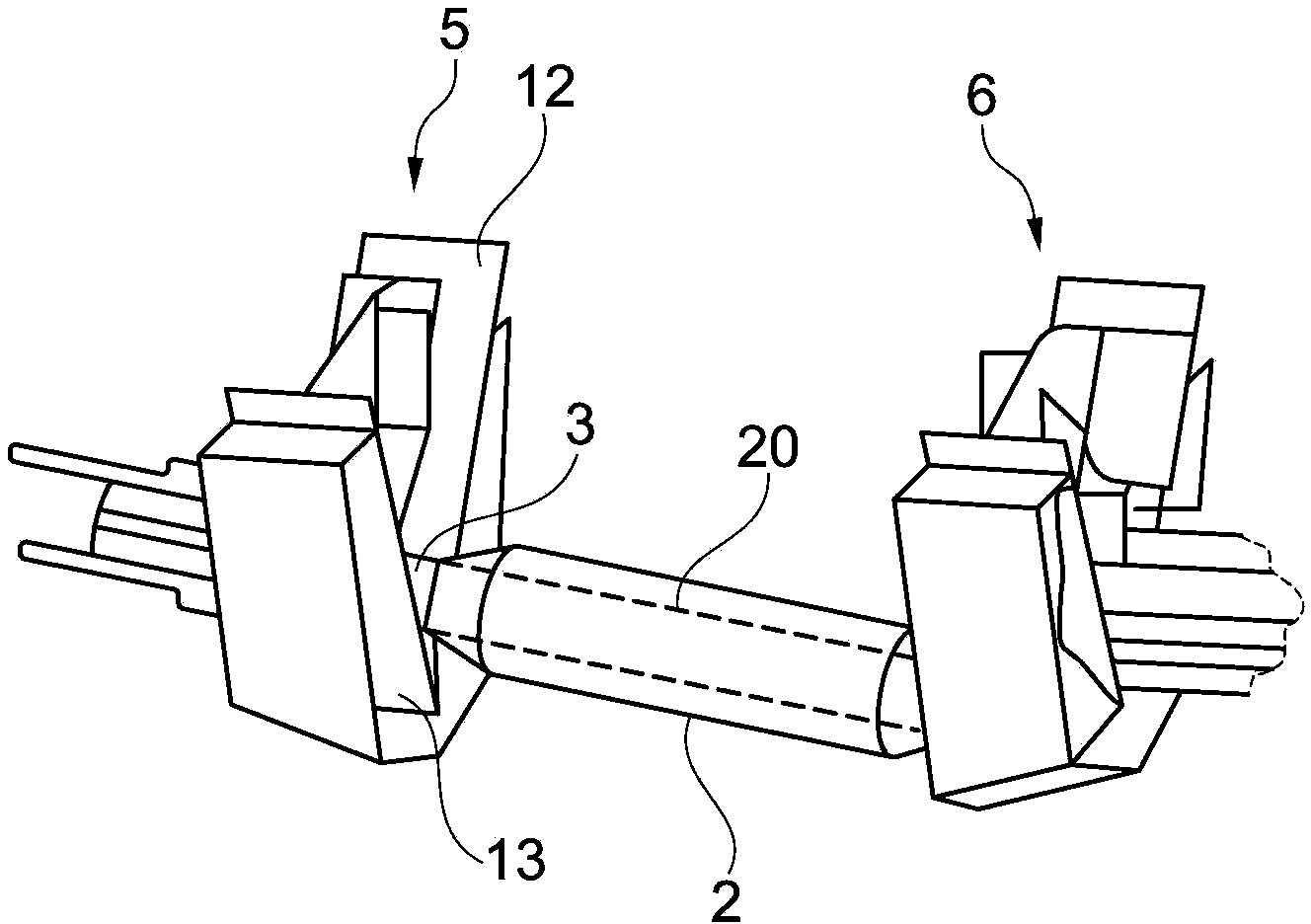

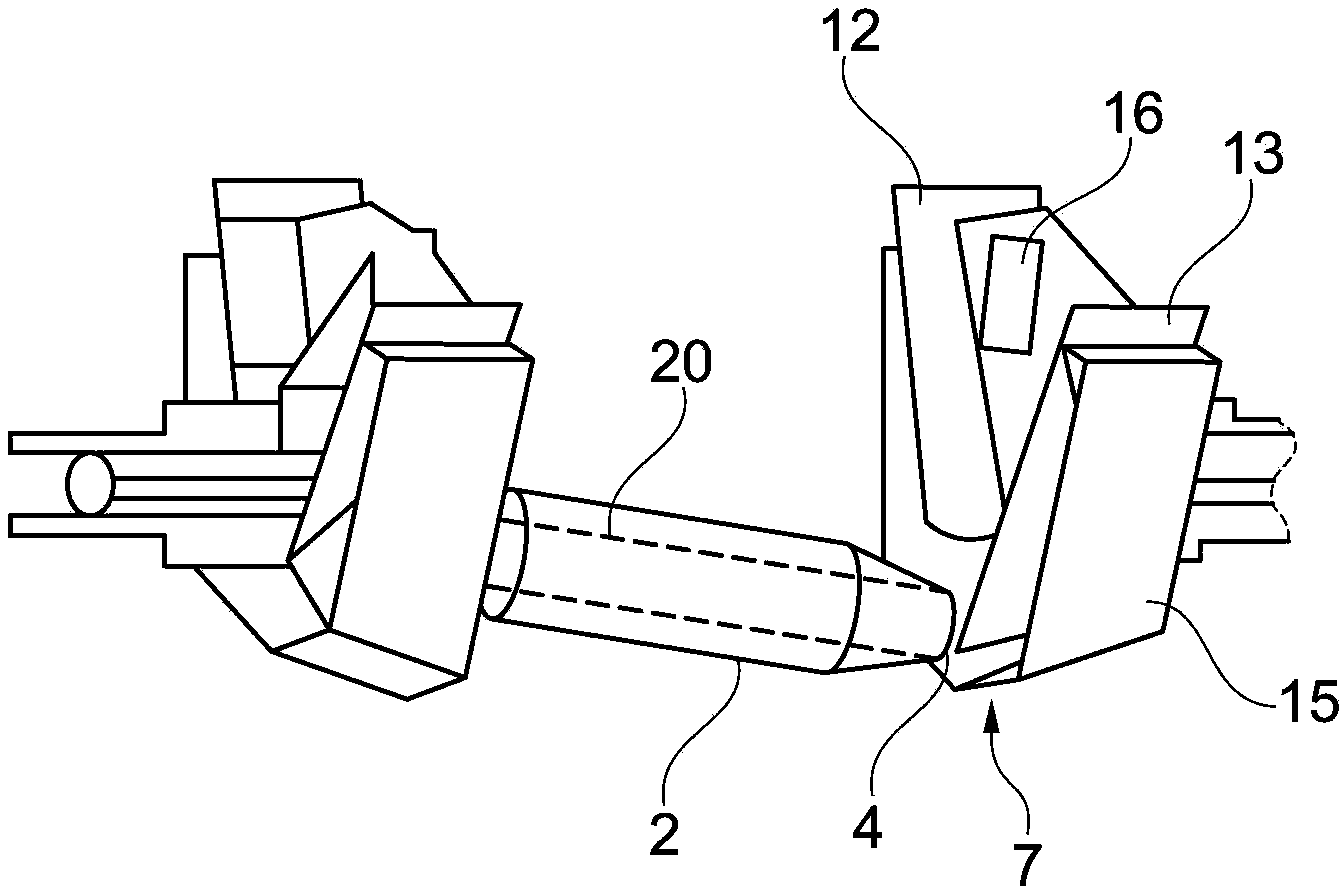

[0041] figure 1 The device 1 according to the invention for inverting bobbins 2 and bobbins 20 is shown. The function of the device 1 will be described below with respect to the bobbin 2 . However, this function also applies to the cop bobbin 20 as well. The cop bobbins 20 , which are largely covered by the winding of the cop 2 , are indicated by dashed lines. The device 1 has two opposite holders 5 and 6 for bobbin ends, wherein the holders 5 , 6 are arranged and formed symmetrically with respect to a horizontal plane lying between the two holders 5 , 6 . Each bracket 5 , 6 is configured as a funnel-shaped profile 11 formed by two funnel plates 12 , 13 . The funnel plates 12 and 13 are mounted on a profile 15 .

[0042] Figure 10 Only the profiled part 15 is shown. The profiled part 15 has two inserts 18 for the funnel plates 12 , 13 . Figure 11 The profile with the funnel plates 12 and 13 installed is shown in side view. The funnel plate 13 now extends as far as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com